3*4 wiring method for medium-pressure distribution network

A wiring method and distribution network technology, applied in the direction of electrical components, circuit devices, emergency power supply arrangements, etc., can solve the problems of high reliability, power supply capacity, weak operation flexibility, power supply capacity cannot meet the power demand, etc., to achieve The effect of high power supply reliability and high power supply capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

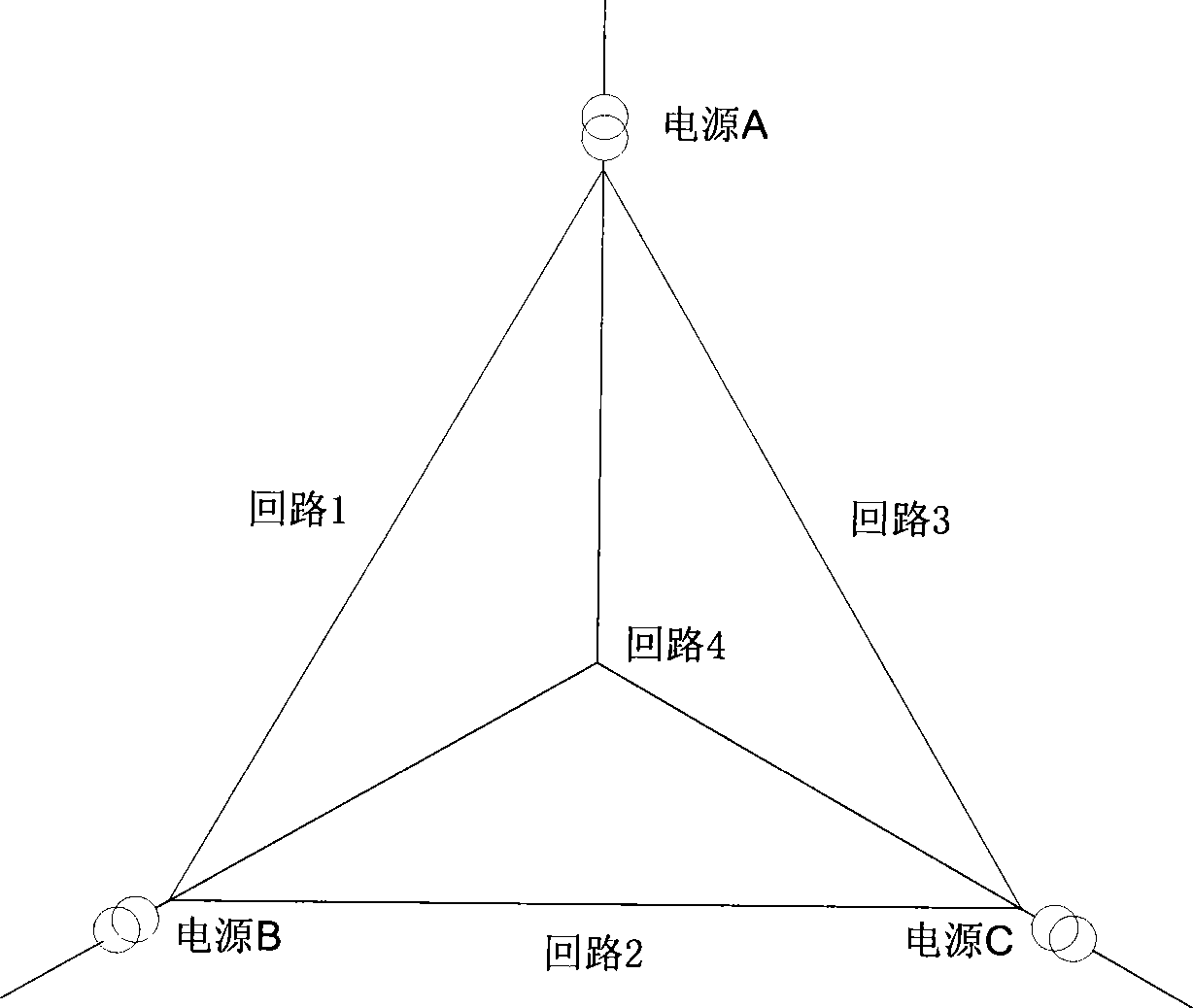

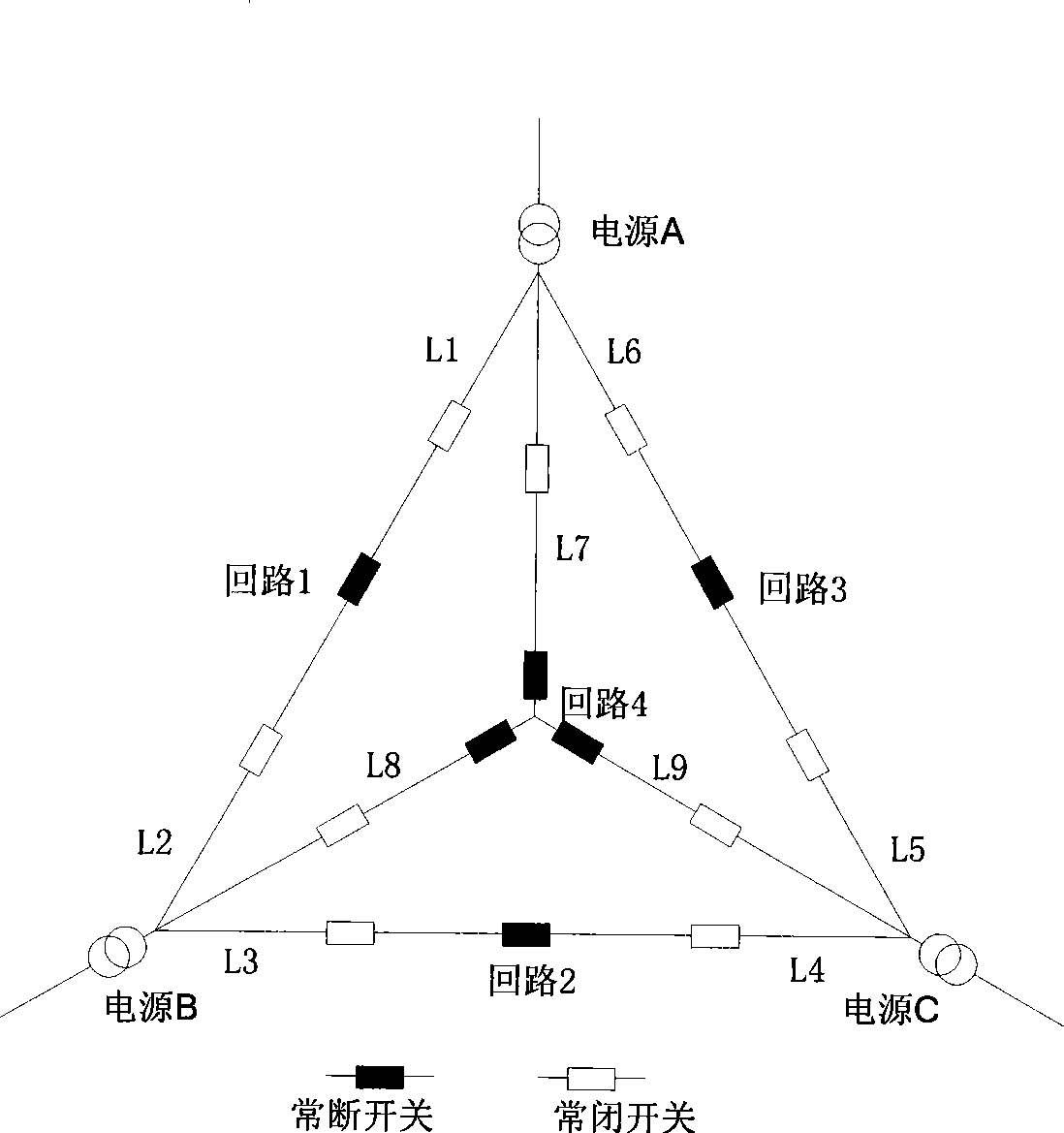

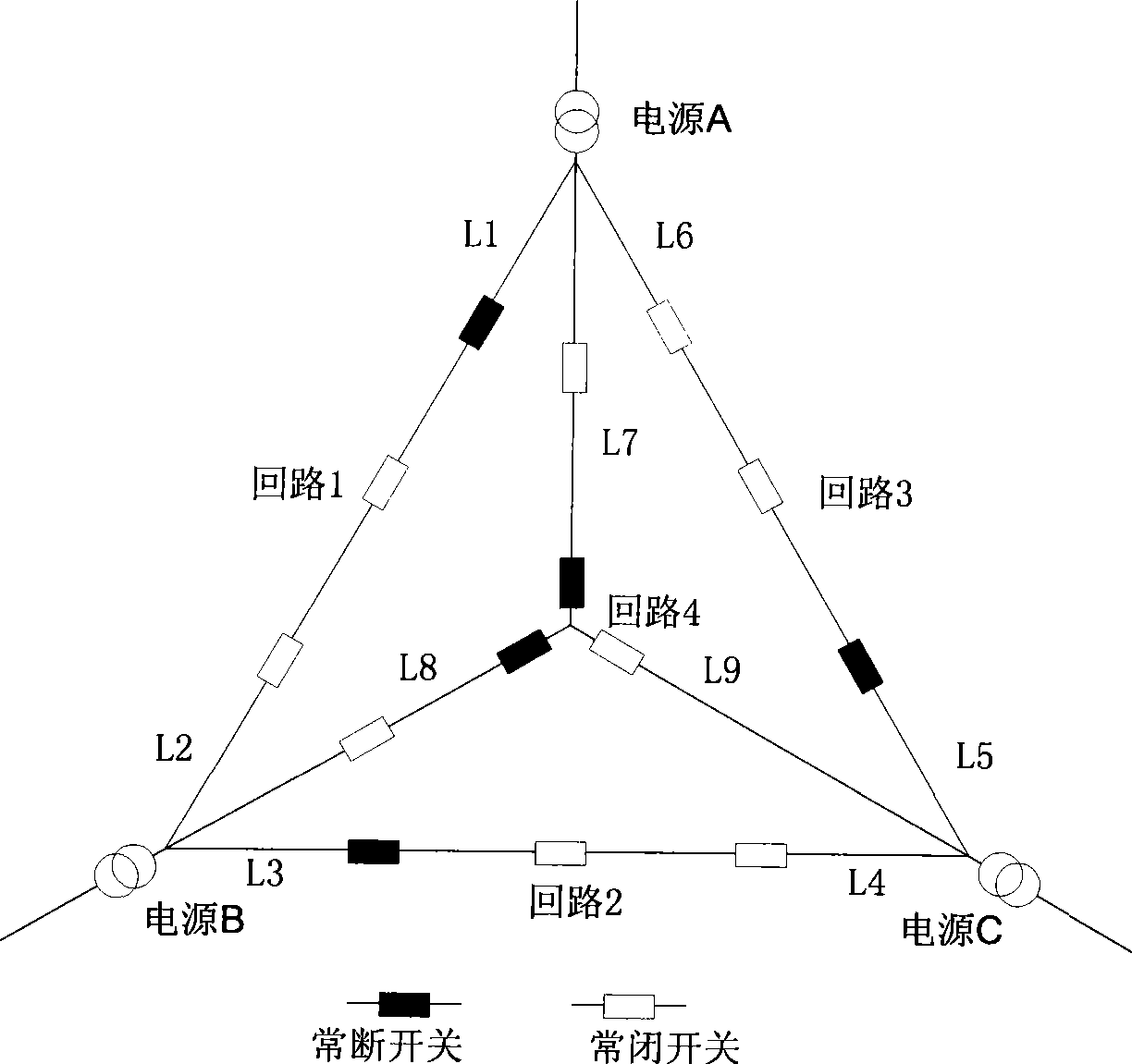

[0057] A comprehensive area in a certain city (including residential, commercial and other loads) has a maximum load of 20MW and covers an area of 5km 2 , the load is approximately evenly distributed, the shape of the area and the road network are as follows Figure 9 shown. Power can be obtained from three substations. The medium voltage level is 10kV. Then the medium-voltage distribution network in this area can adopt the wiring of the present invention.

[0058] Lines L1, L7, L6 come out from power supply A; lines L2, L3, L8 go out from power supply B; lines L4, L5, L9 go out from power supply C. L1 ~ L9 are all reasonable subsections with normally closed switches. L1, L2 are connected through a normally-off switch to form circuit 1, L3, L4 are connected through a normally-off switch to form circuit 2, L5, L6 are connected through a normally-off switch to form circuit 3, L7, L8, L9 The circuit 4 is formed by connecting three normally-off switches. Each line path is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com