Side panel for heating room and construction process

A plate and edge technology, applied in the field of room heating plates, can solve the problems of difficulty and convenience in arranging heating pipes, and achieve the effect of improving efficiency and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

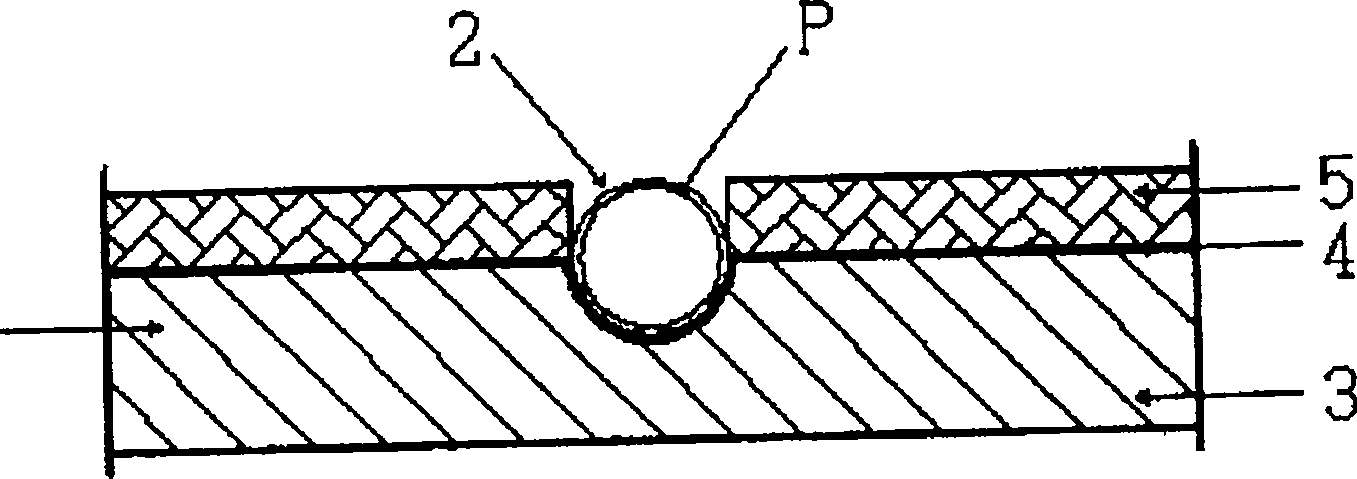

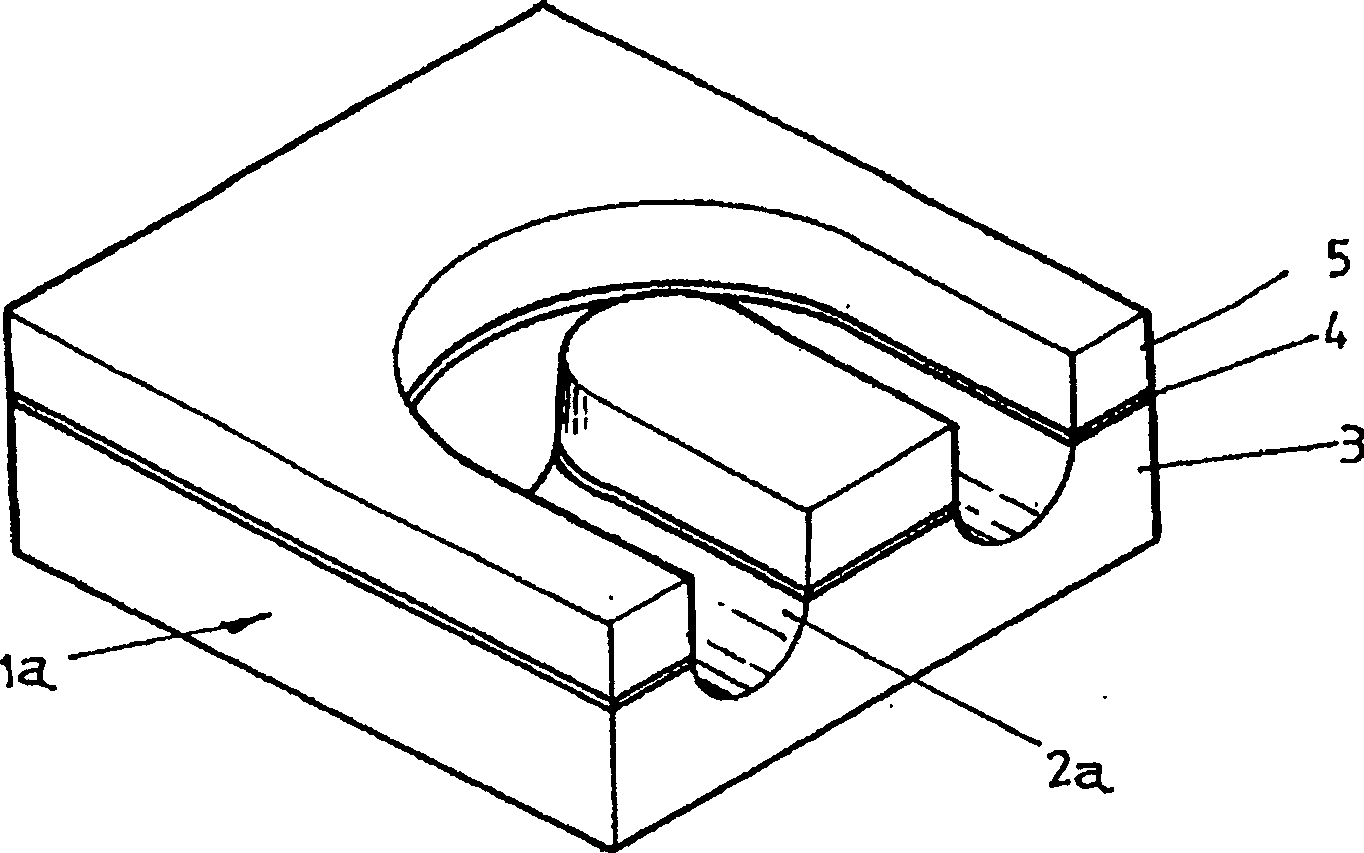

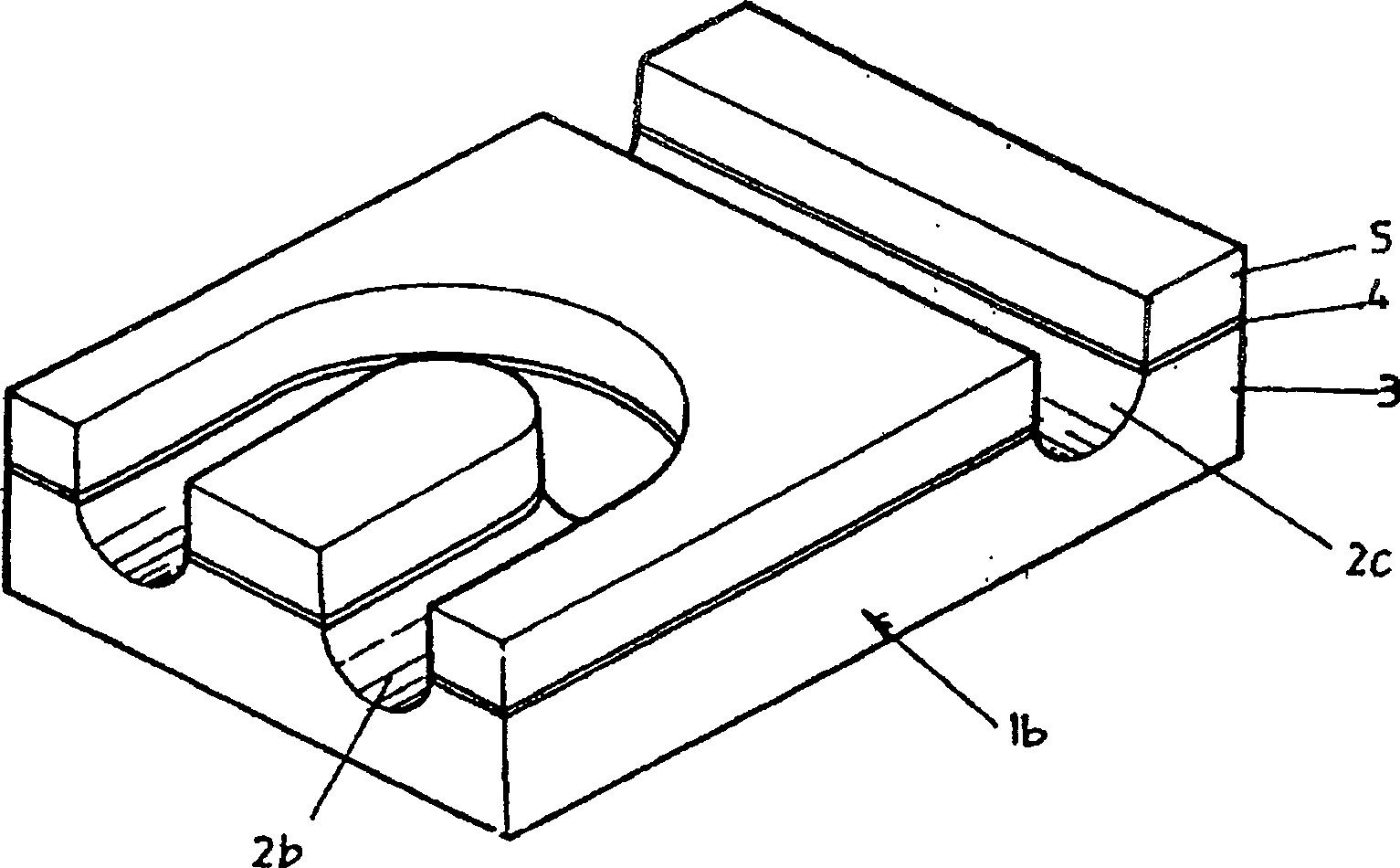

[0033] [33] In the present invention, as shown in FIG. 1, a rectangular central straight panel 1 with a straight groove 2 is arranged in the middle or central part of the floor according to the width and length of the floor of the room.

[0034] [34] If figure 2 with image 3 As shown, in the edge plate 1a in the A part in Fig. 1, the heat transfer sheet 4 formed by thin aluminum, copper, or other metal sheets is arranged on the thermal insulation layer 3 of the edge plate 1a; A heat storage layer 5 is arranged above the heat transfer sheet 4, wherein the heat storage layer 5 is formed by flocculating stone powder with an inorganic flocculation material such as gypsum; And half of it goes deep into the thermal insulation layer 3, thereby enabling the end of the U-shaped groove 2a to be aligned with the end of the groove of the adjacent plate.

[0035] [35] Then, a decorative material not shown in the drawings such as a wooden board or a marble chip is arranged on the heat st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com