Dishware cleaner

A tableware washing machine and cleaning tank technology, applied in the direction of tableware washing machine/rinsing machine, tableware washing machine/rinsing and rinsing machine parts, automatic detection under the control of tableware washing machine/rinsing machine, etc., capable of solving ultrasonic vibrator failures , The ultrasonic vibrator stops working, affects the work of the ultrasonic vibrator, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, one embodiment of the present invention will be described with reference to the drawings. In addition, the same code|symbol is attached|subjected to the same structure as a conventional example, and the description is abbreviate|omitted. In addition, this invention is not limited to this embodiment.

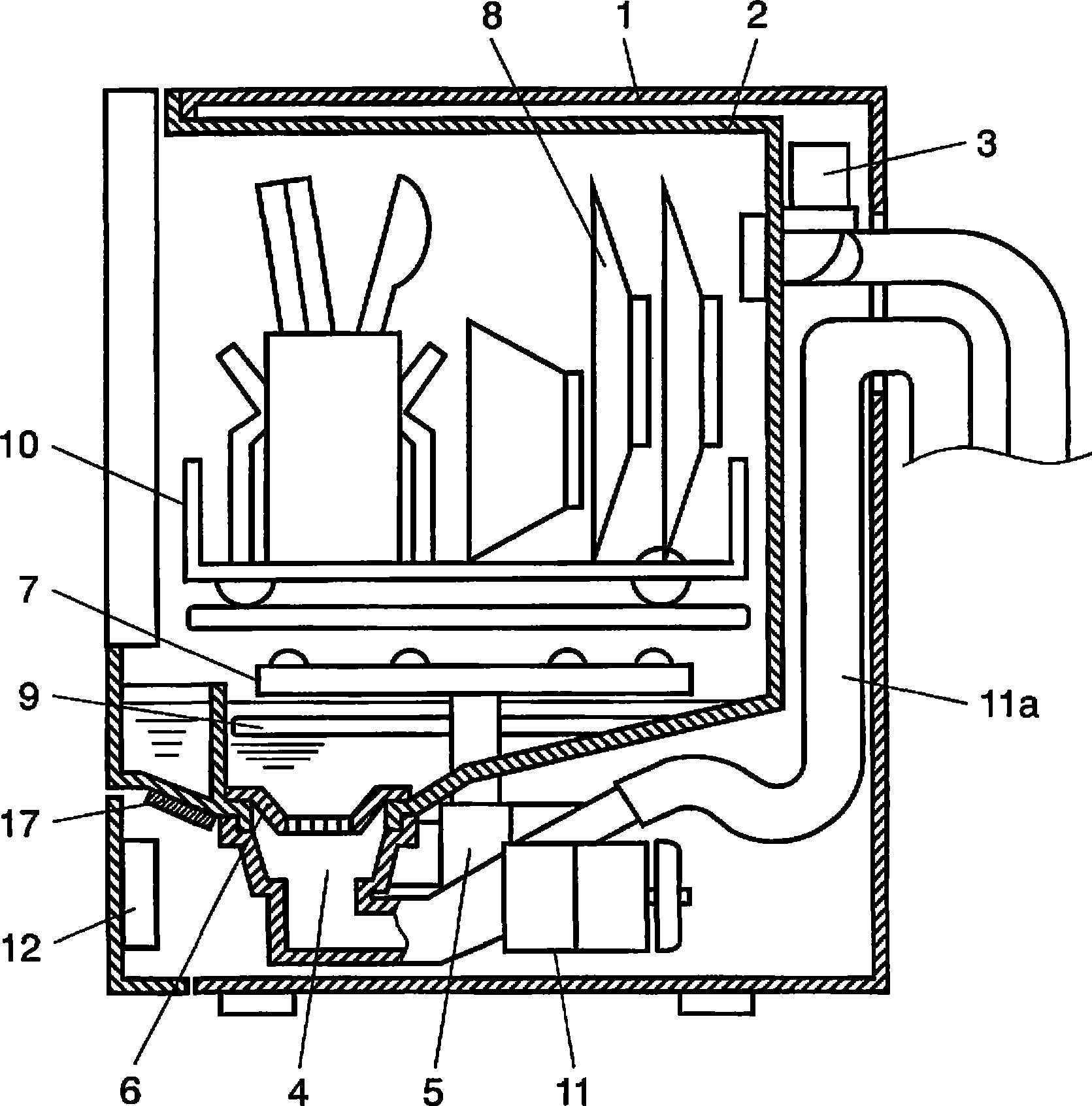

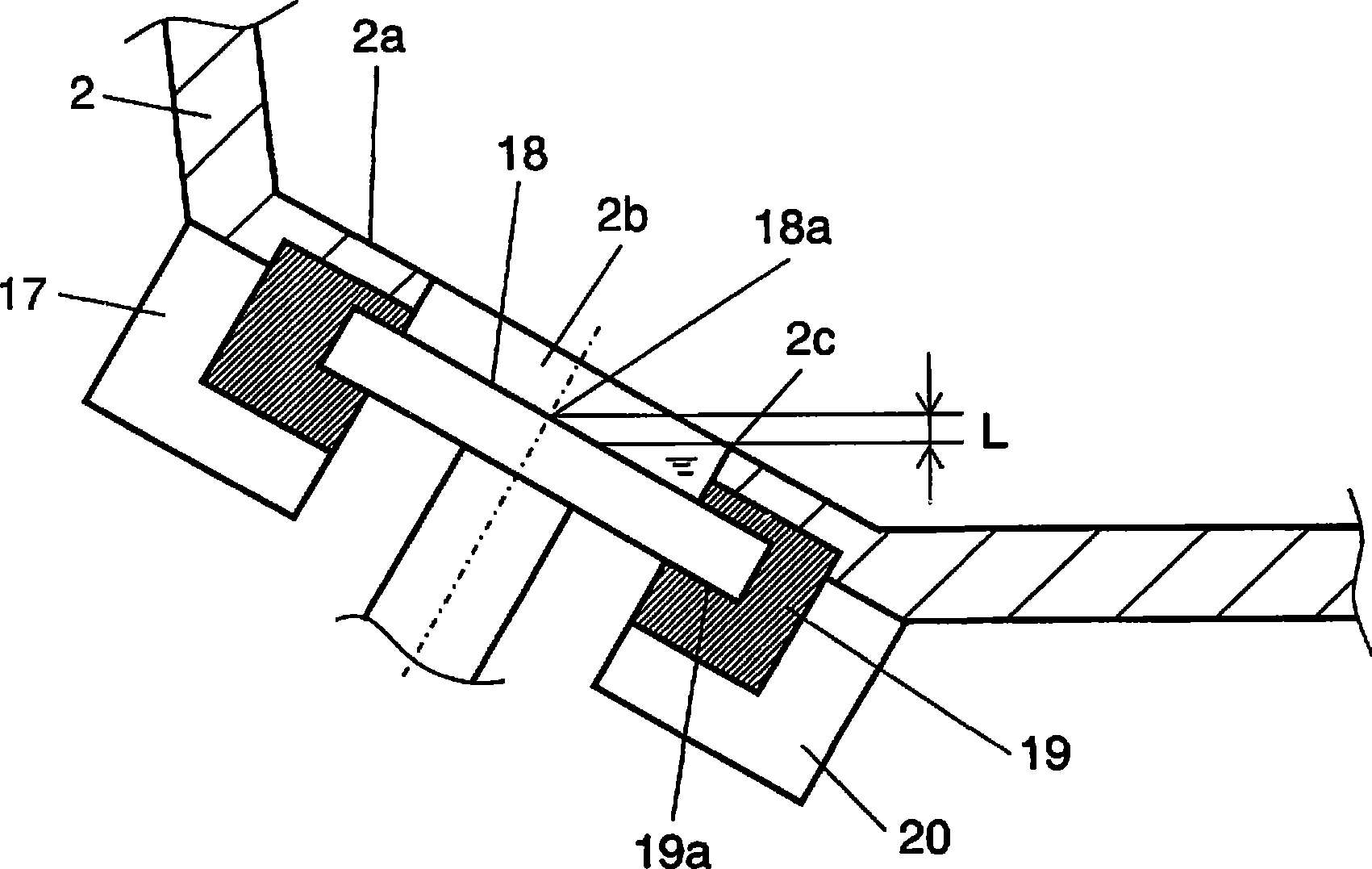

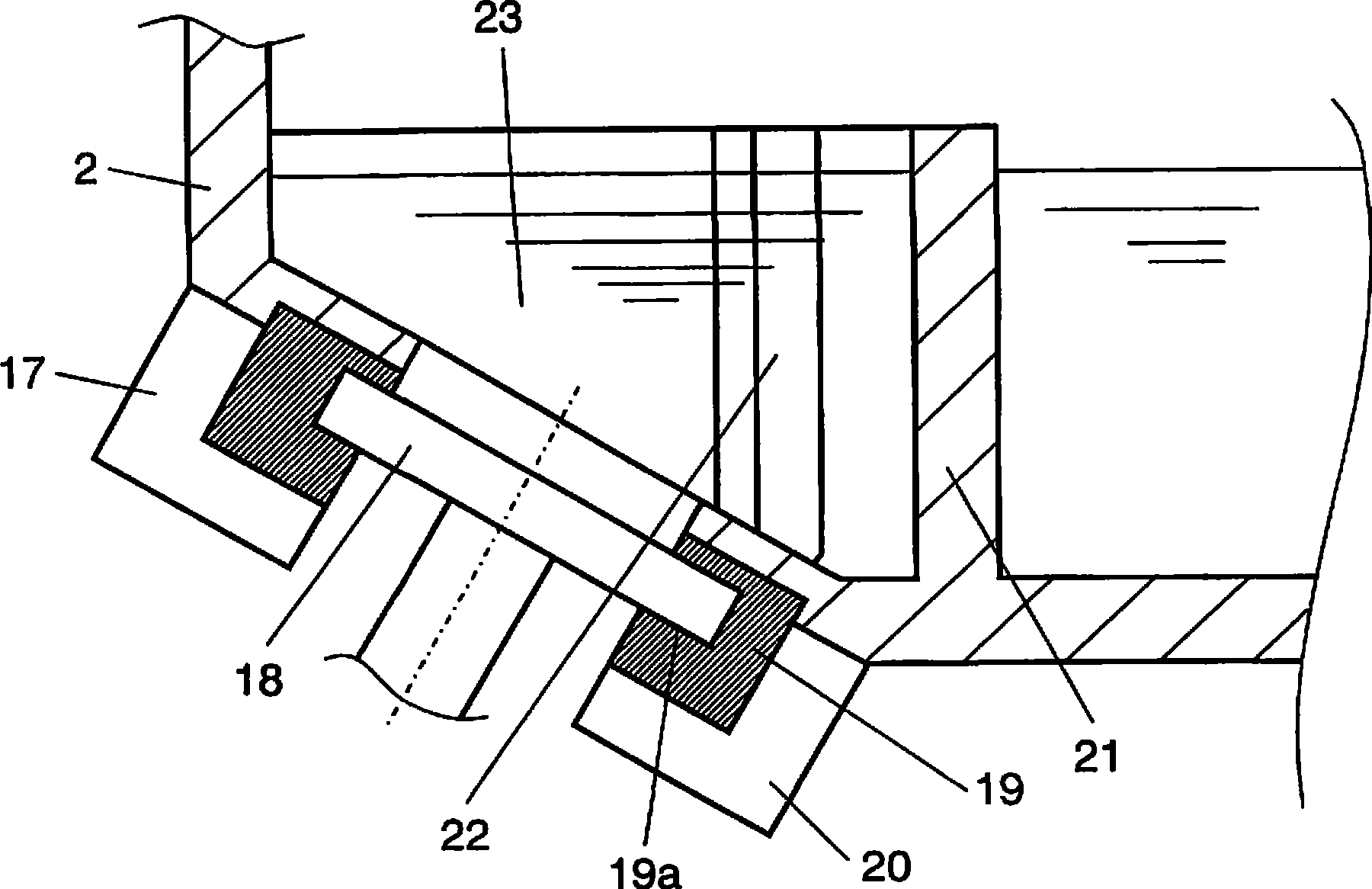

[0019] figure 1 It is a vertical cross-sectional view of a dishwasher according to an embodiment of the present invention, figure 2 and image 3 It is a sectional view of main parts of the dishwasher. exist Figure 1 ~ Figure 3 Among them, the main body 1 of the dishwasher is provided with a washing tank 2 for accommodating objects to be cleaned such as tableware. Water or hot water is supplied into the washing tank 2 by a water supply valve 3 . A drainage hole 4 is provided at the bottom of the cleaning tank 2 . A washer pump 5 driven by a motor (not shown) is installed in communication with the drain hole 4 . Washing water is circulated in the wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com