Lifting device for screw rod hoister

A technology of lifting device and hoist, which is applied in the direction of lifting device, winch device, etc., can solve the problems of lifting frame shaking, large resistance, nut wear and other problems, and achieve the effect of safe and stable lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

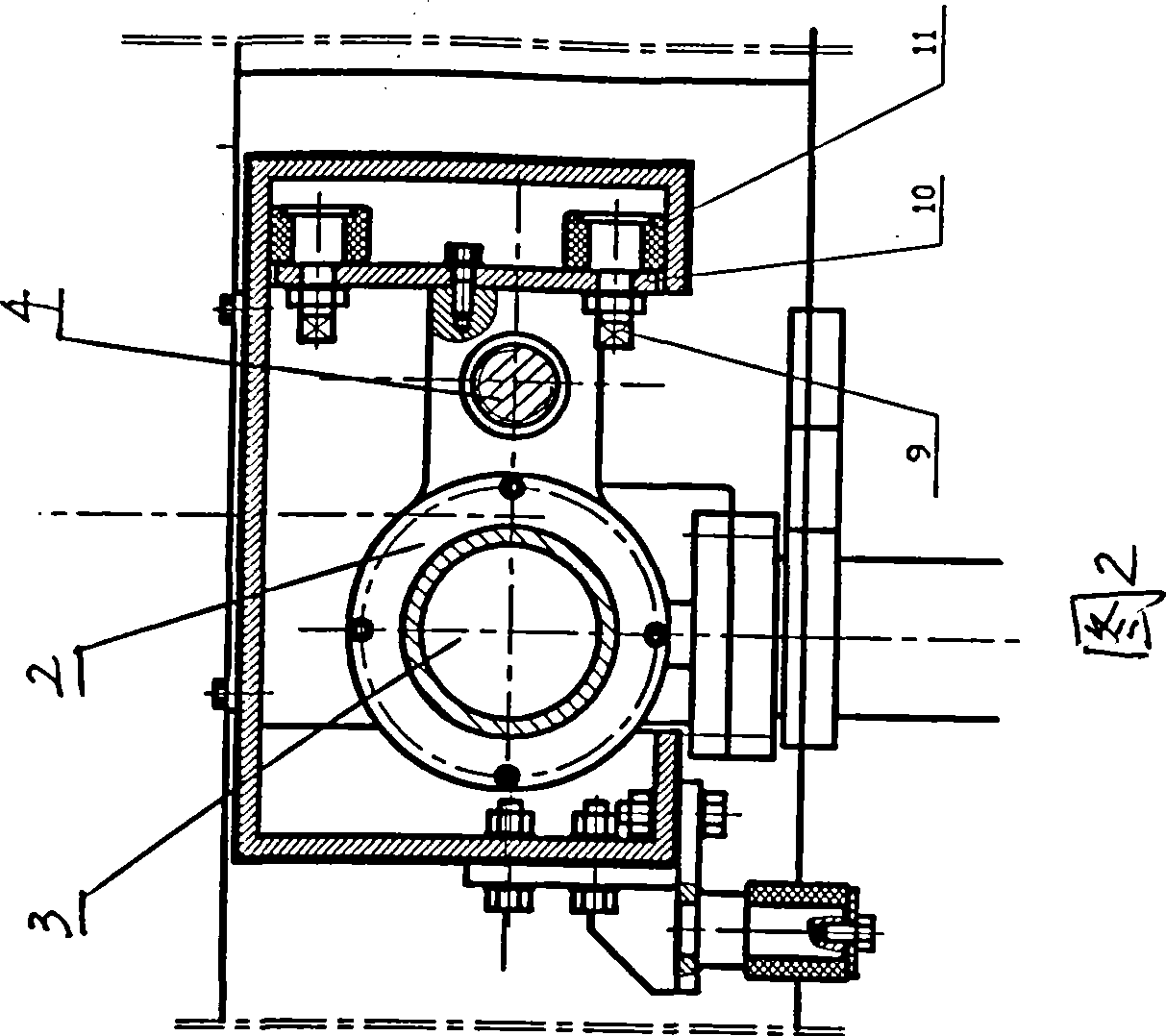

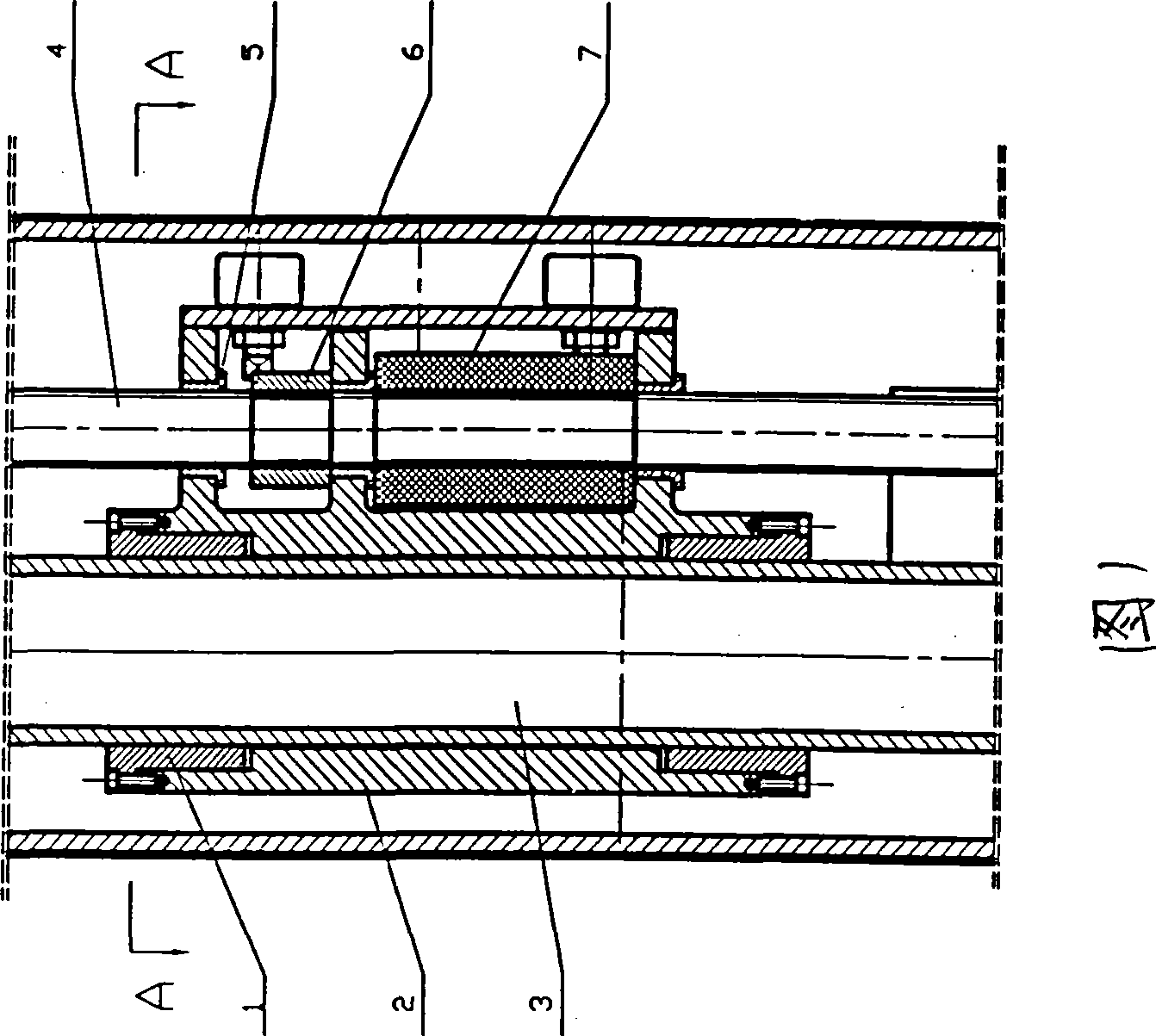

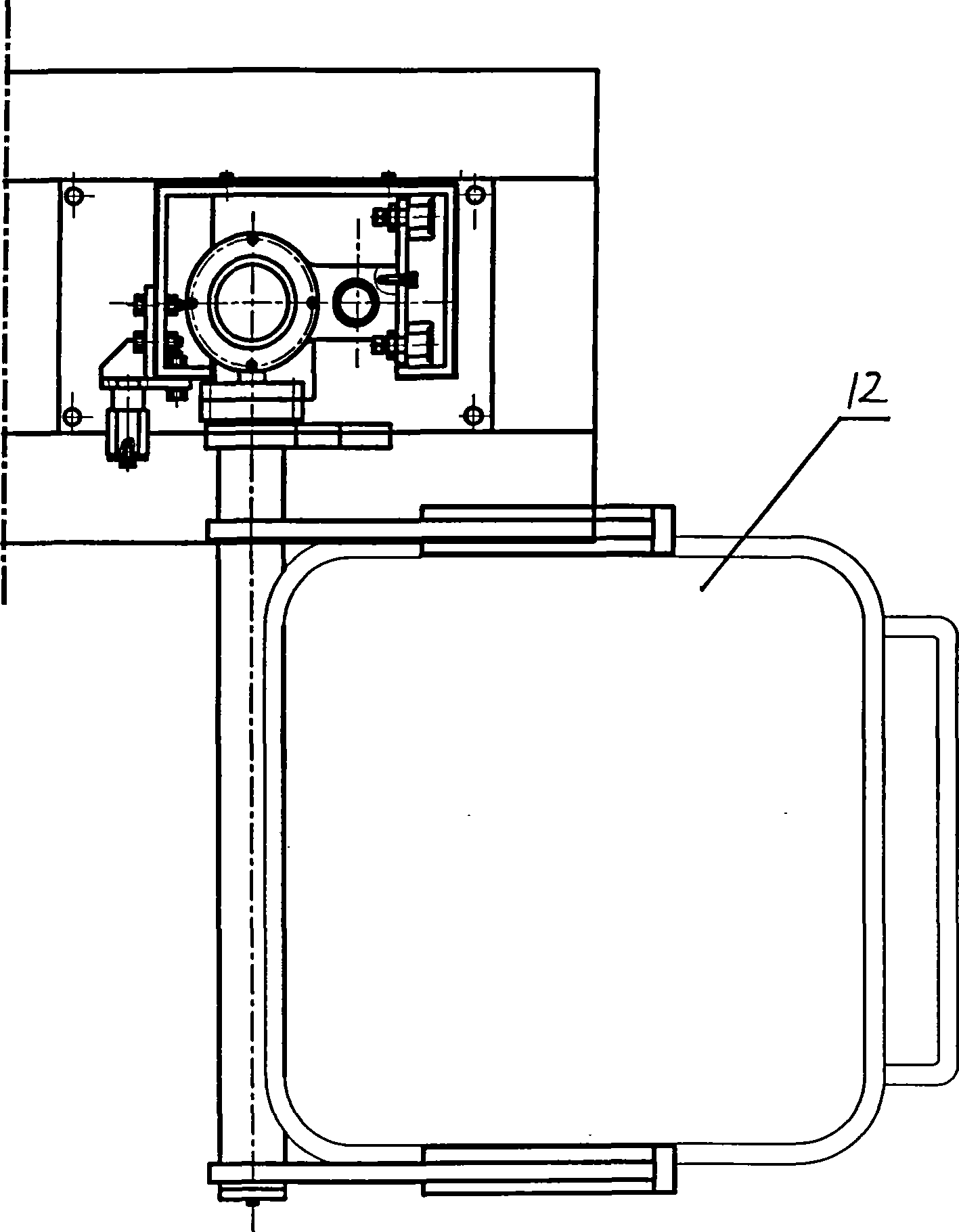

[0010] Embodiments of the present invention will be further described below with reference to the accompanying drawings.

[0011] As shown in the figure, the present invention includes cast iron nuts 6 and nylon nuts 7. Under the rotation of the helical screw 4 installed on the underframe and the frame, the column support on the guide column 3 installed on the underframe and the frame is driven. 2. With the copper sleeve 5 on the column support 2, the lifting sleeve 1 moves up and down on the guide column 3, so that the food loading cart 12 on the rack can be lifted. At the same time, the column support 2 is connected to the support plate 10. In order to make the rollers cling to the channel steel when they are worn up and down, an eccentric shaft 9 that can adjust the distance of the rollers is installed, and four rollers 11 are connected to make the four rollers 11 Lift and roll in the channel steel on the frame, so that the material vehicle frame on the guide column 3 can n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com