Joining column structure

A technology of combining columns and joints, applied in the direction of connecting components, threaded fasteners, nuts, etc., can solve the problems of shell depression, poor surface flatness and aesthetics of the shell, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

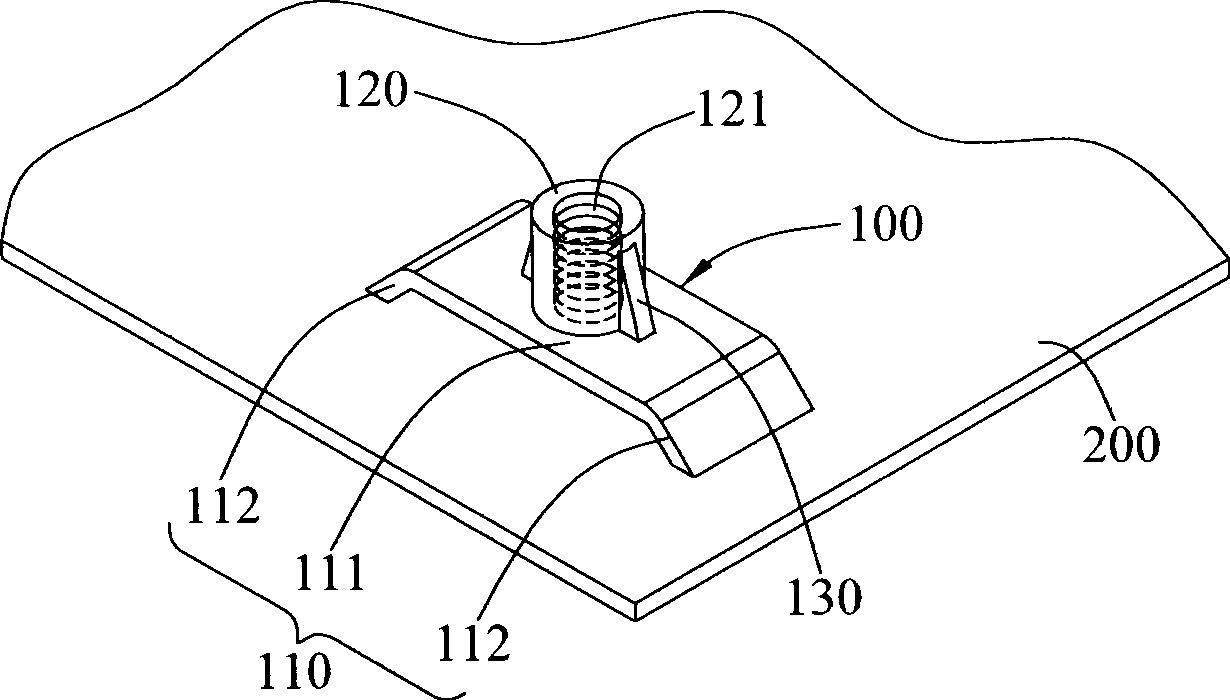

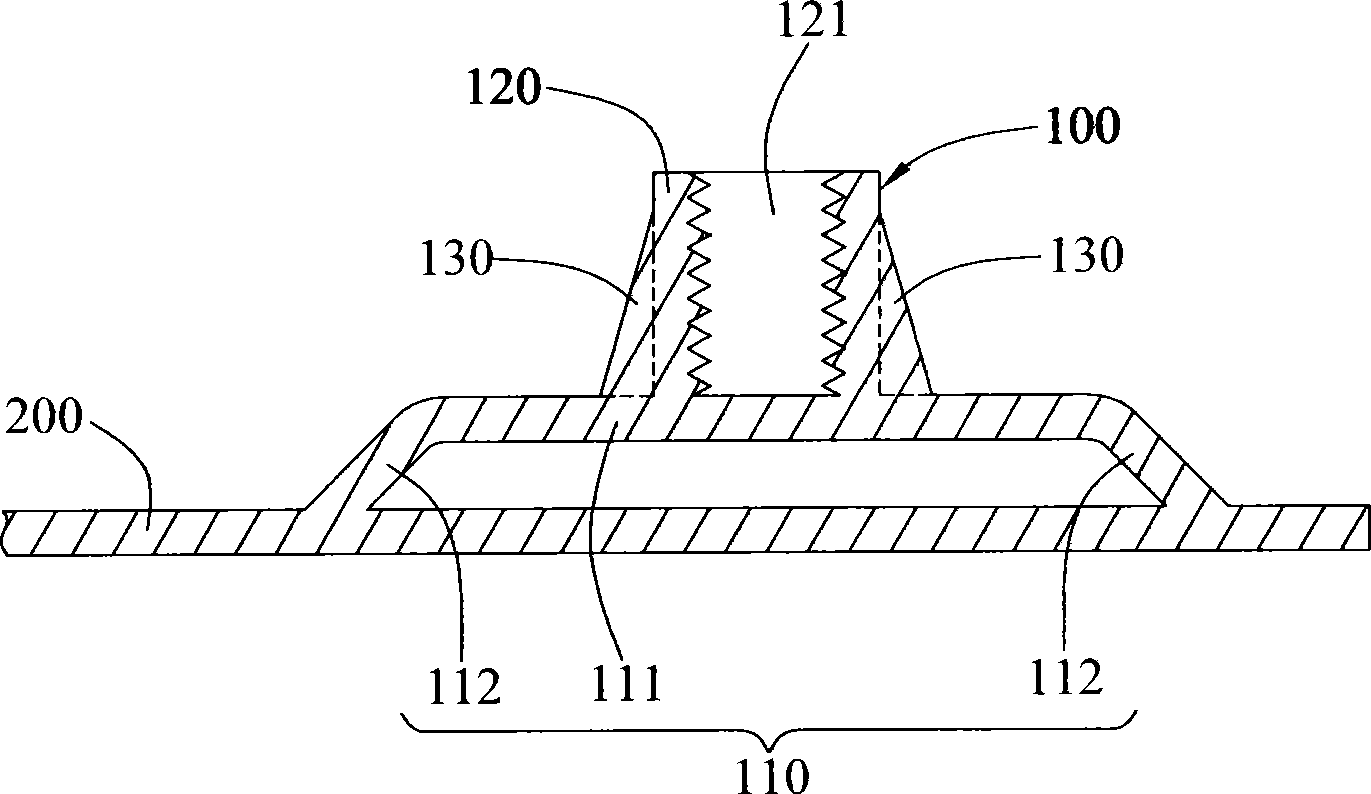

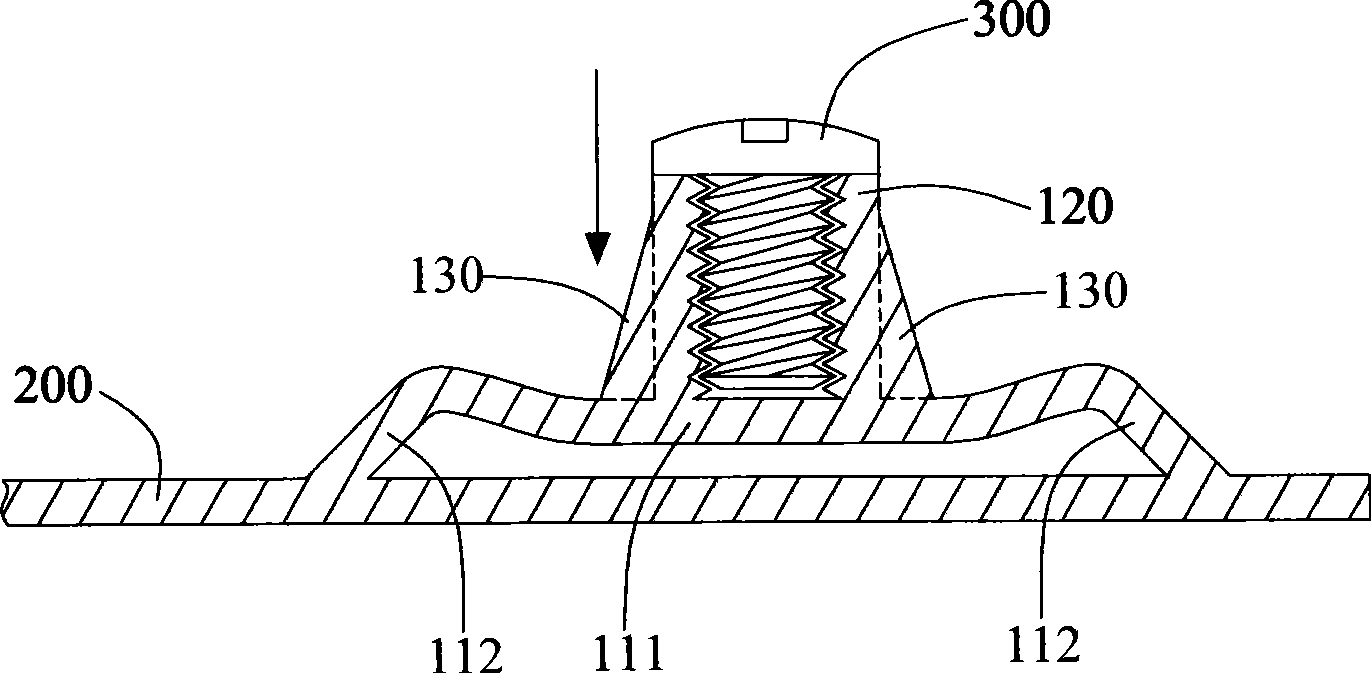

[0019] see figure 1 and figure 2 The coupling column structure 100 of the present invention is formed on a housing 200 in an integral and inseparable relationship, for example, the coupling column 100 is formed on the housing 200 by plastic injection molding, so that the coupling column 100 and the housing 200 are integrally formed structure.

[0020] The coupling post 100 includes a suspension 110 and a coupling 120. The suspension 110 has a bearing part 111 of a flat plate structure, and a connecting part 112 is respectively extended from two opposite sides of the bearing part 111, and the two connecting parts 112 It is connected to the housing 200 at an inclined angle, so that the bearing part 111 is suspended on the housing 200 with a distance from the housing 200 .

[0021] The coupling part 120 is a cylindrical structure integrally formed with the suspension part 110 , and a screw hole 121 is provided at the top of the coupling part 120 . The coupling part 120 is dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com