Method for producing water-containing composition of ethylene-vinyl alcohol copolymer

A vinyl alcohol copolymer and a production method technology are applied in the field of EVOH water-containing composition production, which can solve problems such as catheter blockage, inability to continuously perform water replacement of EVOH solution, and reduction in condensation efficiency, and achieve inhibition of catheter blockage and condensation efficiency. The effect of reducing and suppressing the decrease in productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] Hereinafter, an Example and a comparative example are given and this embodiment is demonstrated more concretely, However, Unless the summary is exceeded, this invention is not limited to description of a following example.

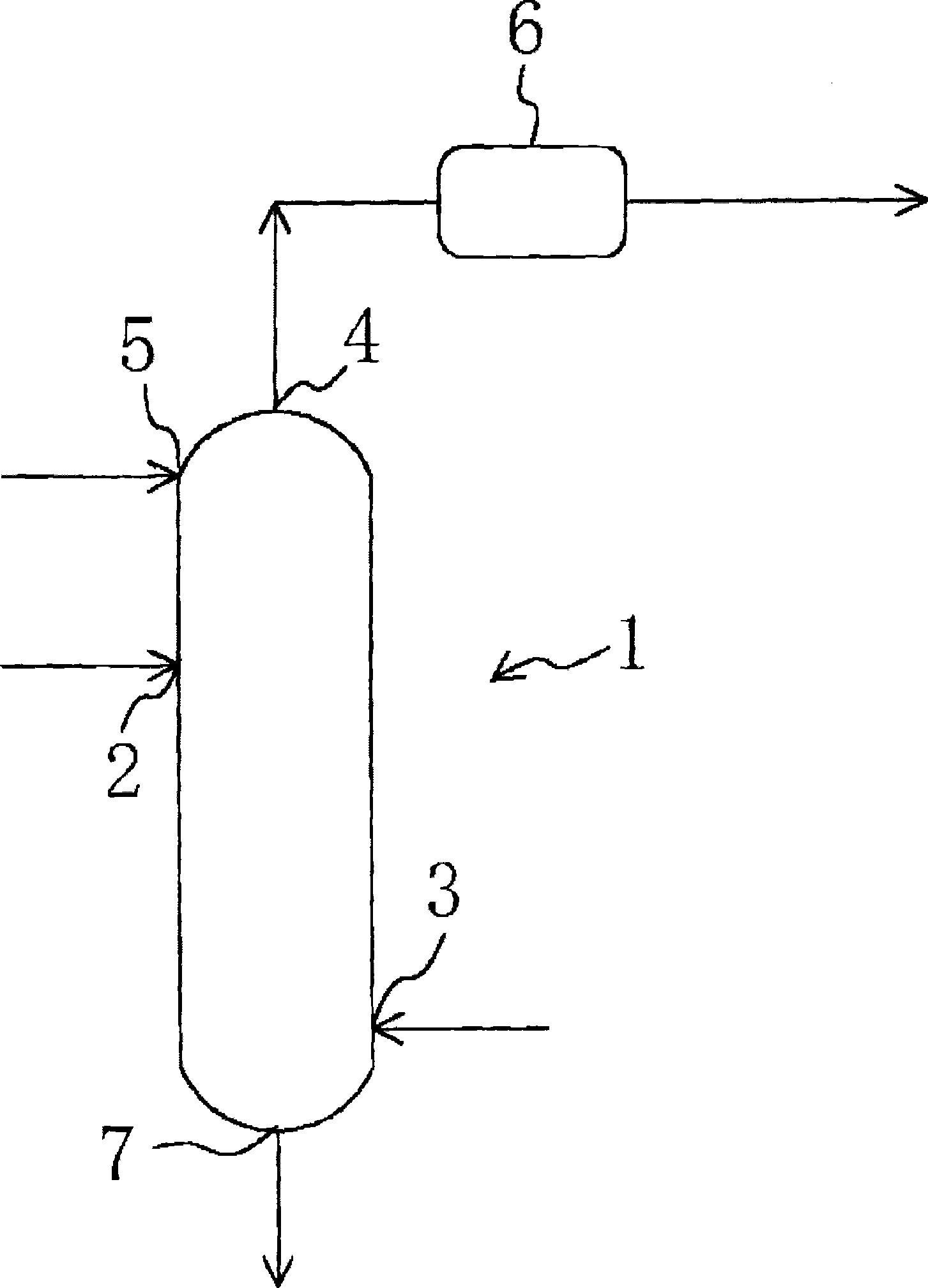

[0045] (Example) A methanol solution (EVOH 30% by mass) containing EVOH with an ethylene content of 44 mol% and a degree of saponification of 99.7 mol% is supplied (1000 parts by mass / hour) to the second stage tray from the top of a 10-layer plate column, Water vapor was supplied (100 parts by mass / hour) from the lowermost tray. In addition, water was supplied to the uppermost tray. The temperature in the tower was 90° C. (column top), and the pressure was 0.1 MPaG (column top). The methanol vapor and water vapor distilled off from the top of the tower are condensed in a condenser and recovered as methanol aqueous solution. An EVOH aqueous composition (EVOH 40% by mass, methanol / water=80 / 20) was withdrawn from the bottom of the column. After the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com