Train speeding machine

A technology for trains and locomotives, applied in the field of train speed-increasing devices, can solve the problems of high cost of new materials, high energy consumption, etc., and achieve the effects of convenient operation, fast acceleration and fast braking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

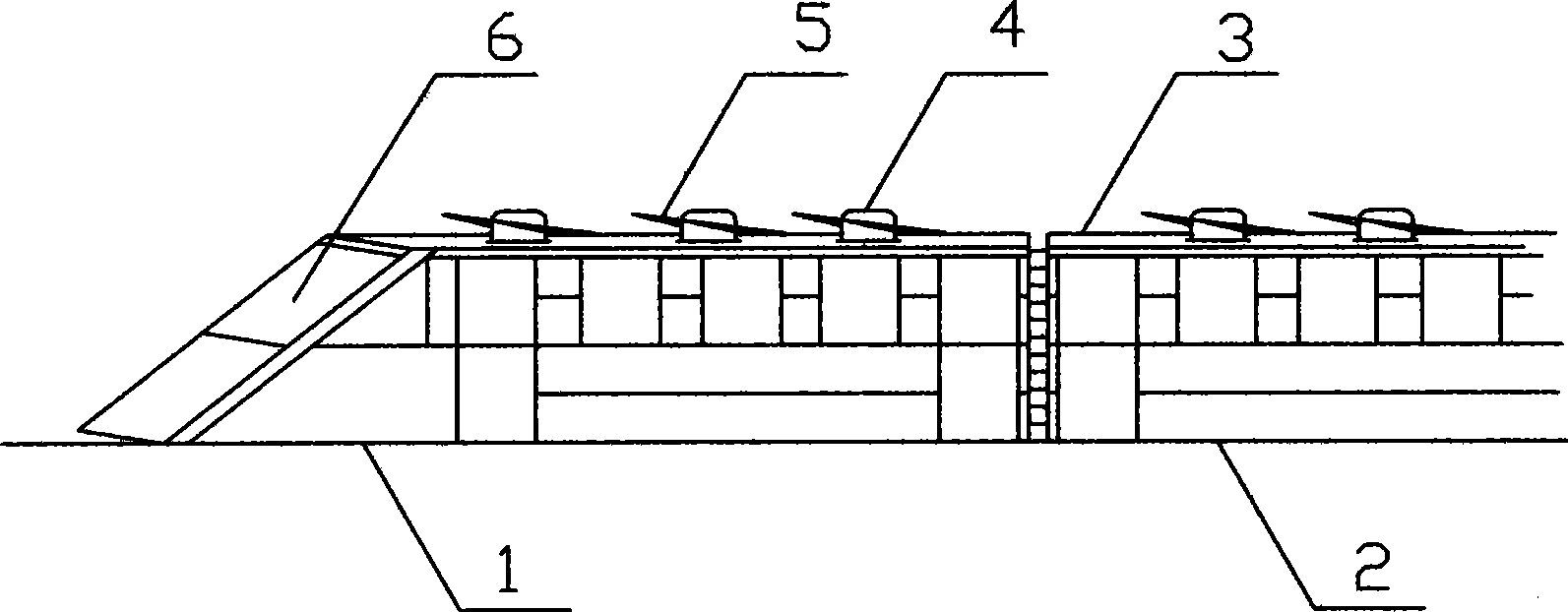

[0009] In the figure, a train speed-increasing device, which includes a locomotive 1 and a car body 2, is characterized in that: a number of brackets 4 are provided on the top 3 of the locomotive 1 and the car body 2, and the brackets 4 are provided with flying parts that can rotate back and forth. Wing 5 is provided with controller 6 in the headstock. The angle of flying wing 5 is elevation angle when advancing, and the resistance of air is changed into lifting force. Reduce the weight of the train to achieve the purpose of increasing the speed of the train. When braking, change the angle of its flying wing 5 into a depression angle, increase the air resistance, and convert the air resistance into braking force, which can effectively reduce the wear of the brake pads and shorten the braking time. distance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com