High-speed train resistance increasing and load shedding method and structure

A technology of high-speed trains and resistance plates, which is applied to railway car bodies, brake components, vehicle components, etc., to achieve the effects of reducing power resource consumption, rapidly increasing power resource consumption, and reducing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the purpose, technical solution and advantages of the application more clear, the technical solution in the embodiment of the application will be described in more detail below in conjunction with the drawings in the embodiment of the application.

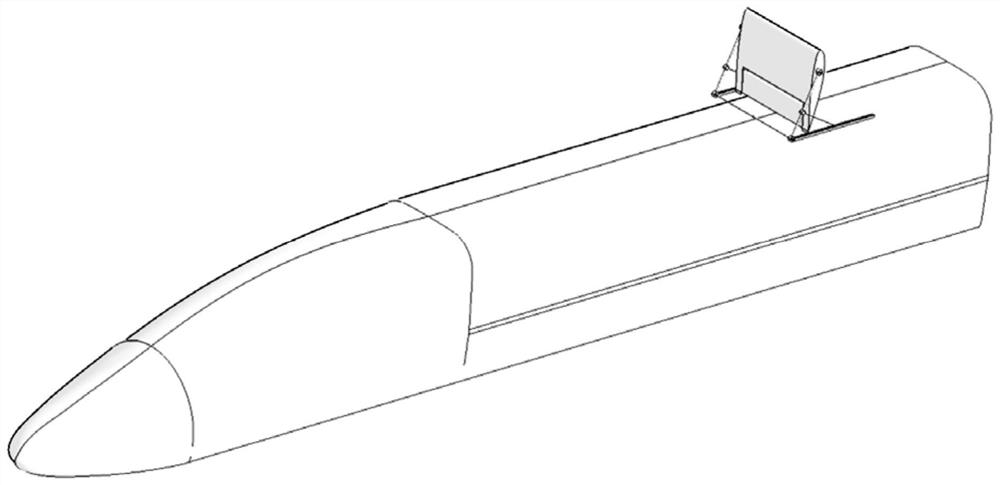

[0026] In order to overcome the relatively simple structure of the traditional drag increasing plate, which is only driven by a simple hydraulic mechanism to realize the problem of increasing the resistance of the plate, this application proposes a method and structure for increasing resistance and reducing load of high-speed trains using supercritical wing technology. It can realize effective resistance increase and deceleration and load reduction and speed increase when the train is running.

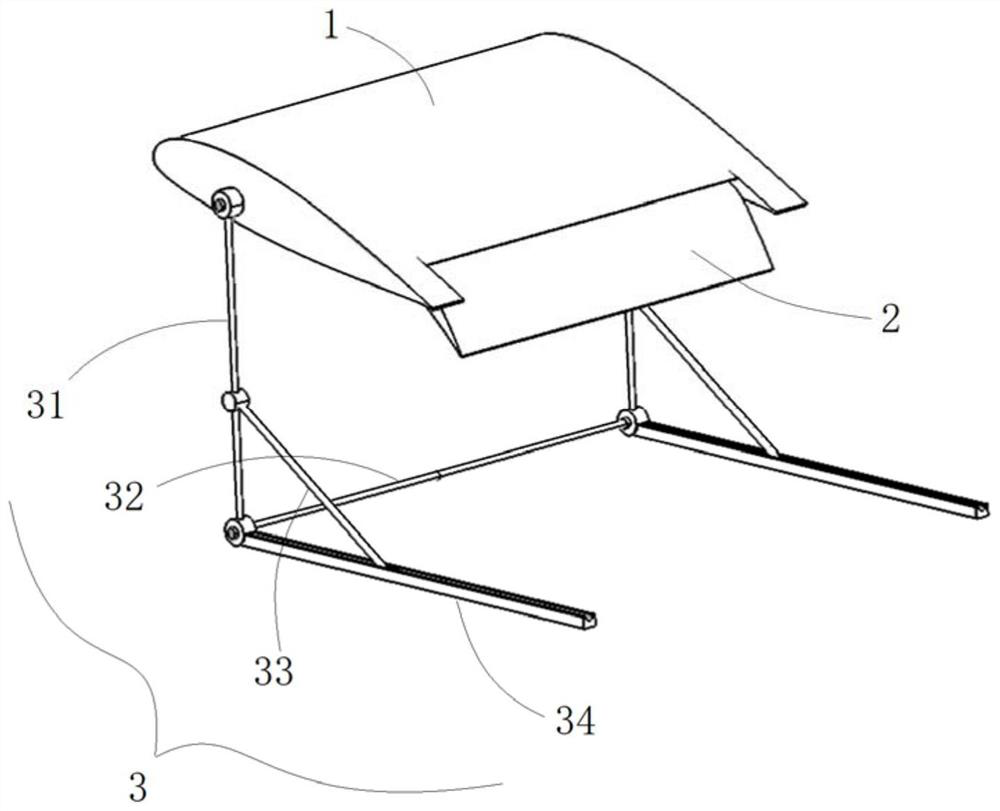

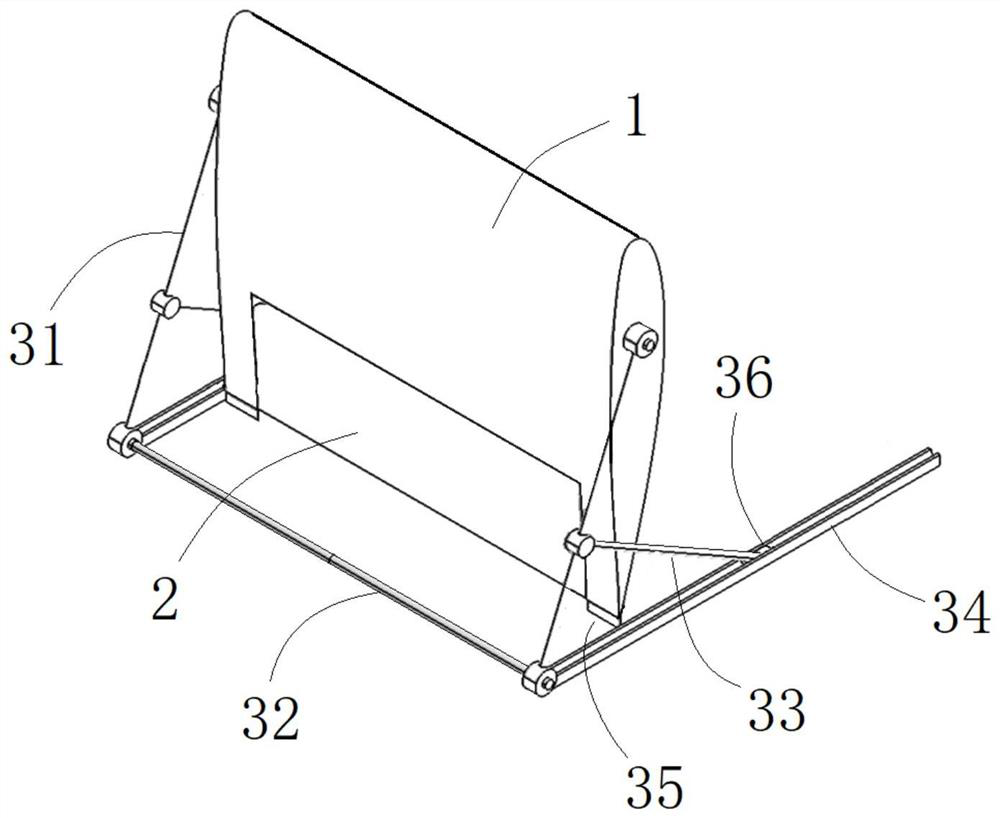

[0027] Such as figure 1 with figure 2 As shown, the high-speed train resistance increase and load reduction method provided by the application draws lessons from the supercritical wing technology in the design of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com