Oil saving stepless speed variator

A technology of continuously variable transmission and sliding disc, which is applied to belts/chains/gears, mechanical equipment, transmission devices, etc., and can solve problems such as large noise, large exhaust emissions, and incomplete transmission of payloads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

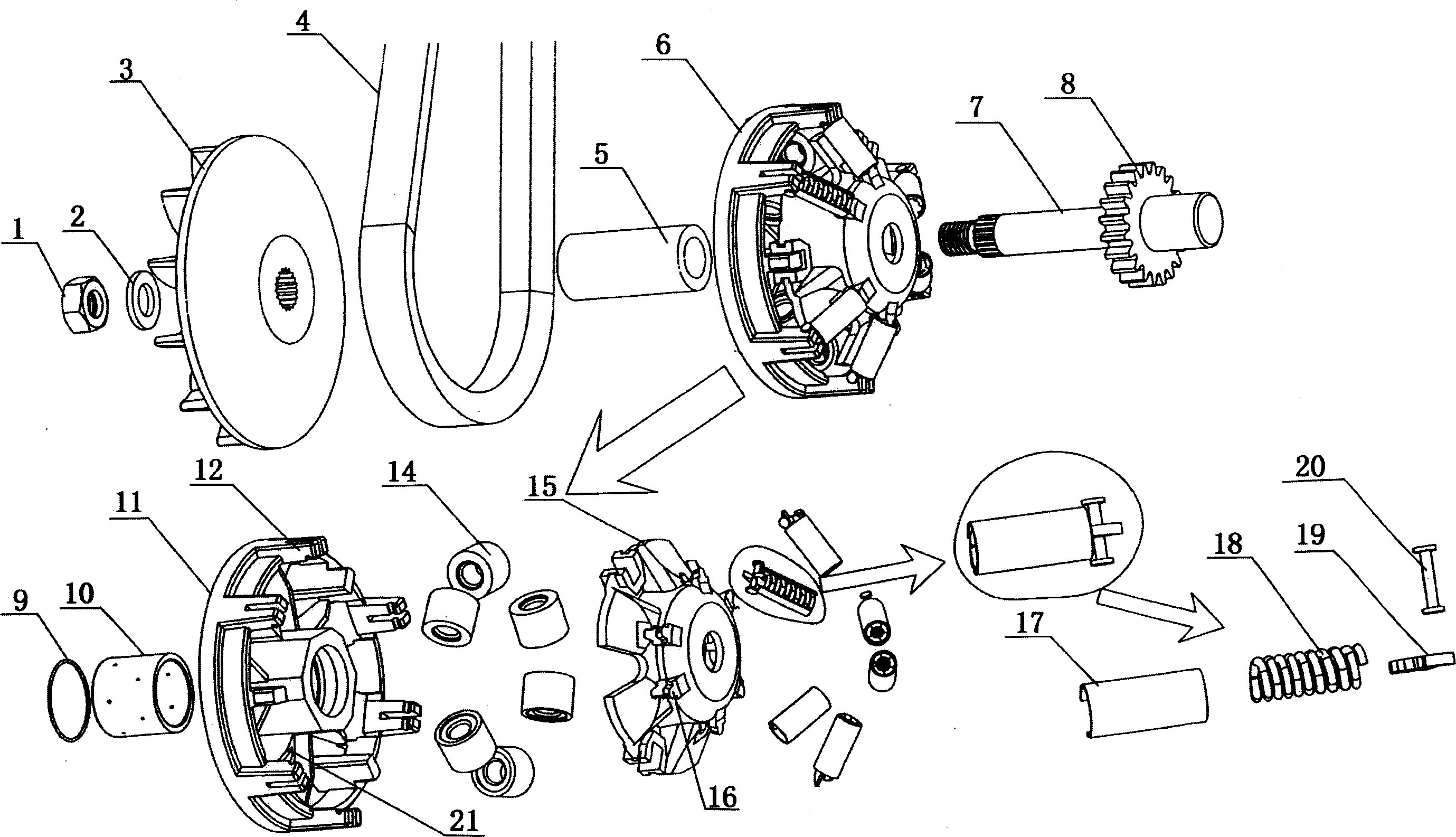

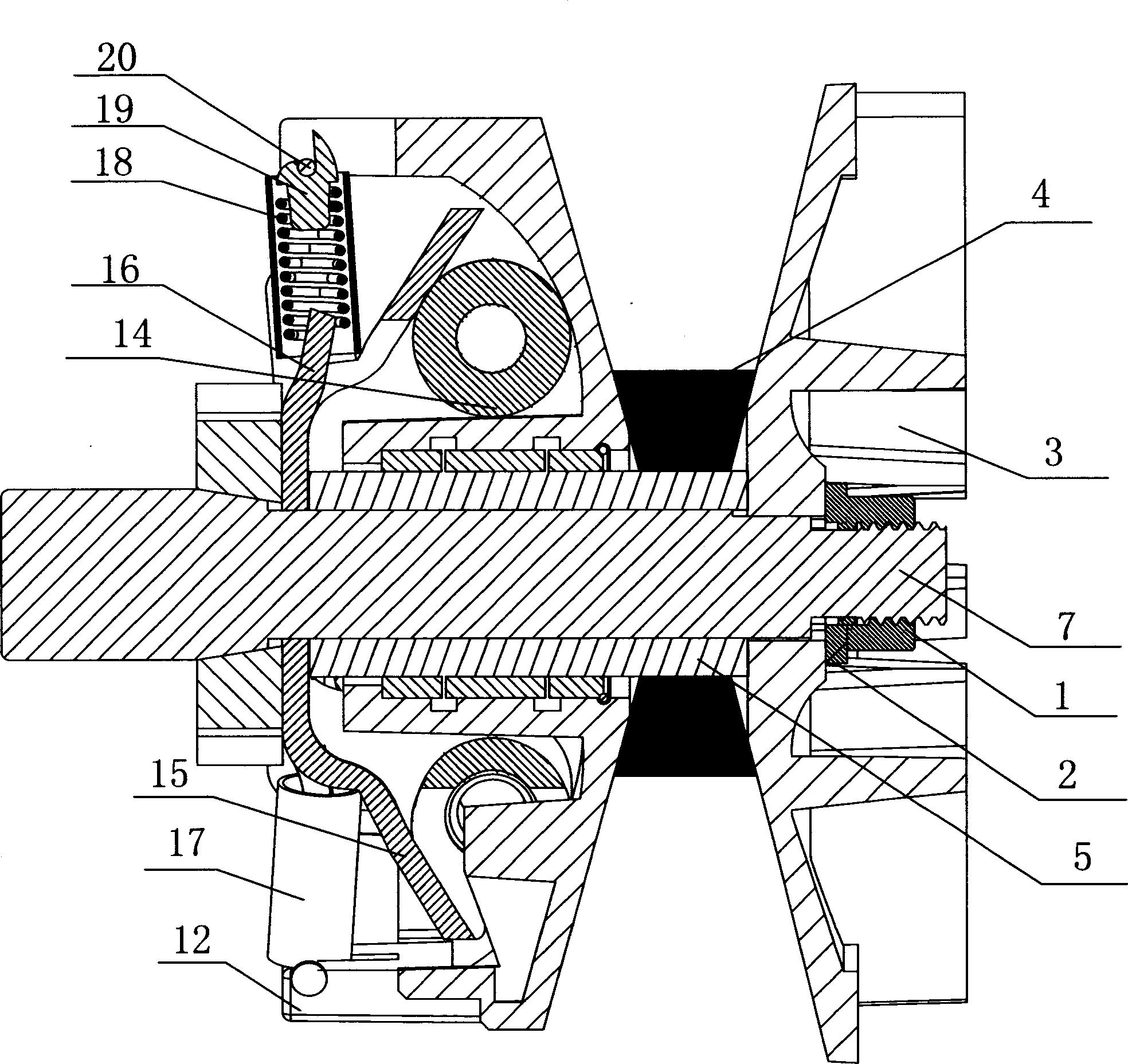

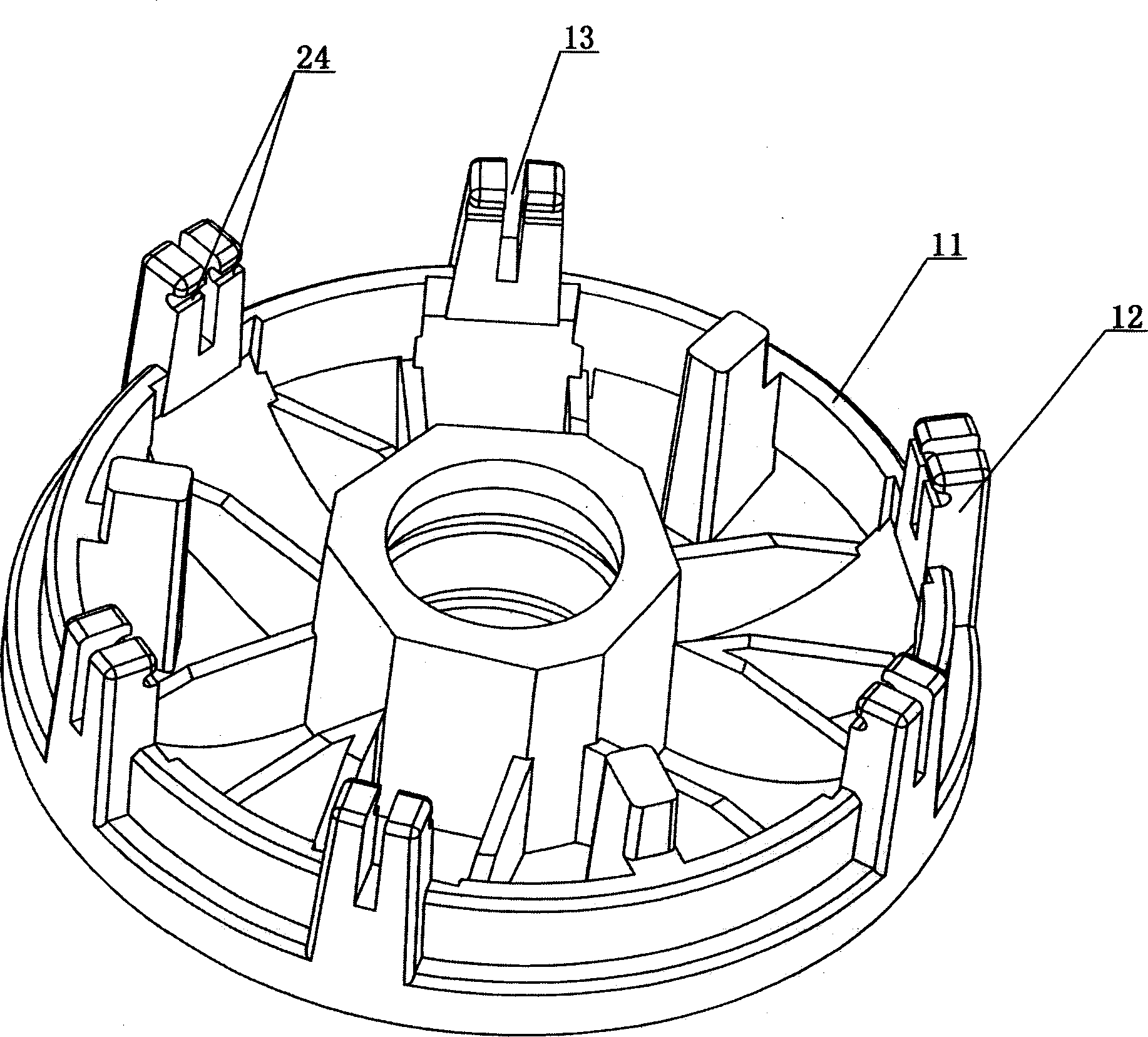

[0011] Below with reference to accompanying drawing, the present invention will be further described: as figure 1 As shown, the fuel-saving continuously variable transmission includes the active sliding disc assembly 6, the main shaft 7, the starting gear 8, the active shifting sliding disc 11, the centrifugal bead 14, the centrifugal bead cover 15 and the track groove 21 in the centrifugal bead cover 15 ; Fan blade disc 3, variable speed belt 4, fixed steel sleeve 5, wear-resistant sleeve washer 9, wear-resistant sleeve 10, active variable speed sliding disc 11, centrifugal bead cover 15 are set on the main shaft 7 in sequence, and the main shaft nut 1 and The gasket 2 is tightened, and the main shaft 7 is provided with a starting gear 8; the centrifugal ball 14 is located in the track groove 21 in the active transmission sliding disc 11, and the transmission belt 4 is sleeved between the blade disc 3 and the active sliding disc assembly 6. on spindle 7, as figure 2 , ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com