Direct heat conducting type solid wood keel ground heating floor

A heat-conducting, keel-based technology, applied in floors, buildings, building structures, etc., can solve the problems of high energy consumption and environmental protection, and achieve the effects of less heat loss, saving glue, and high heat conduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

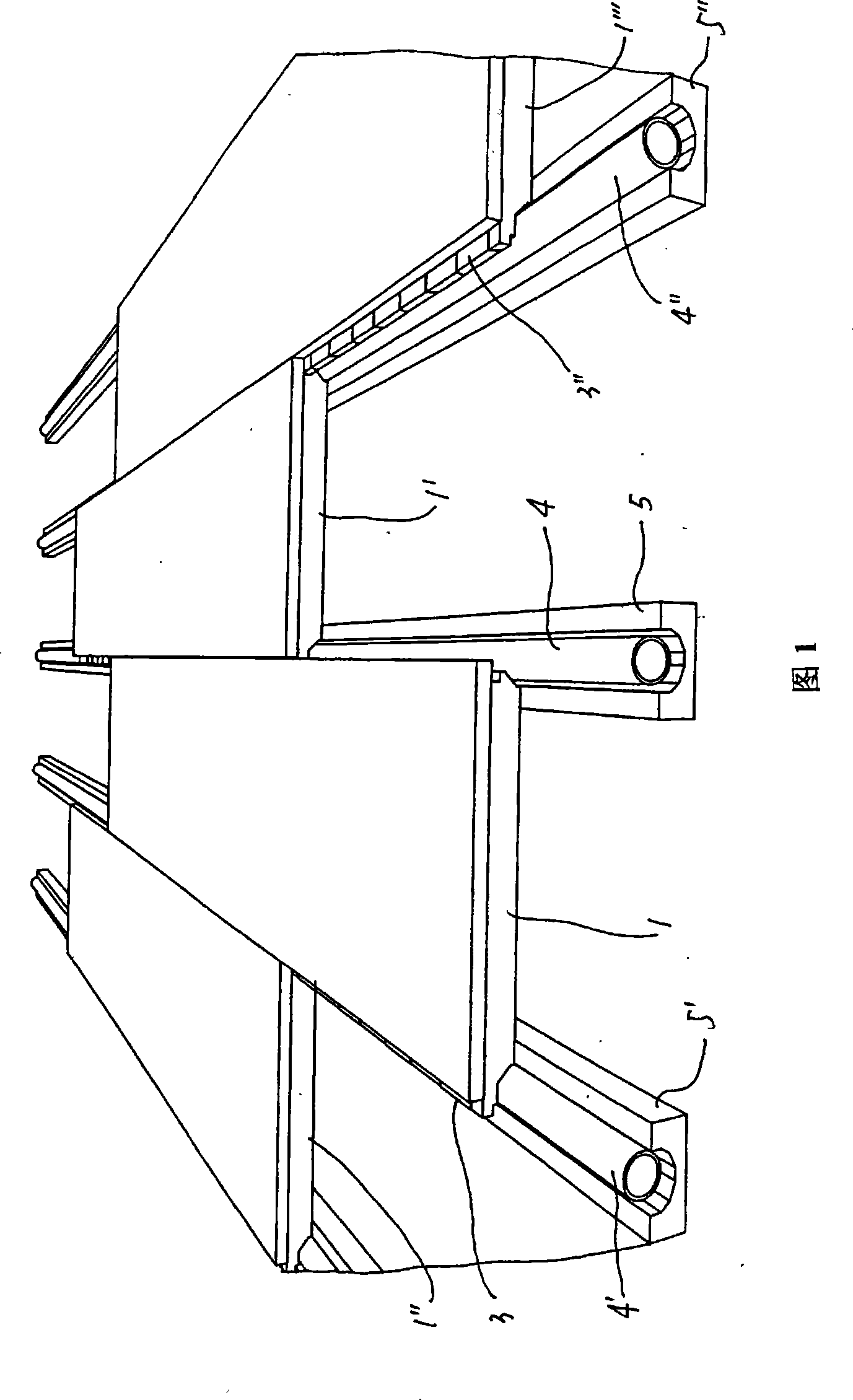

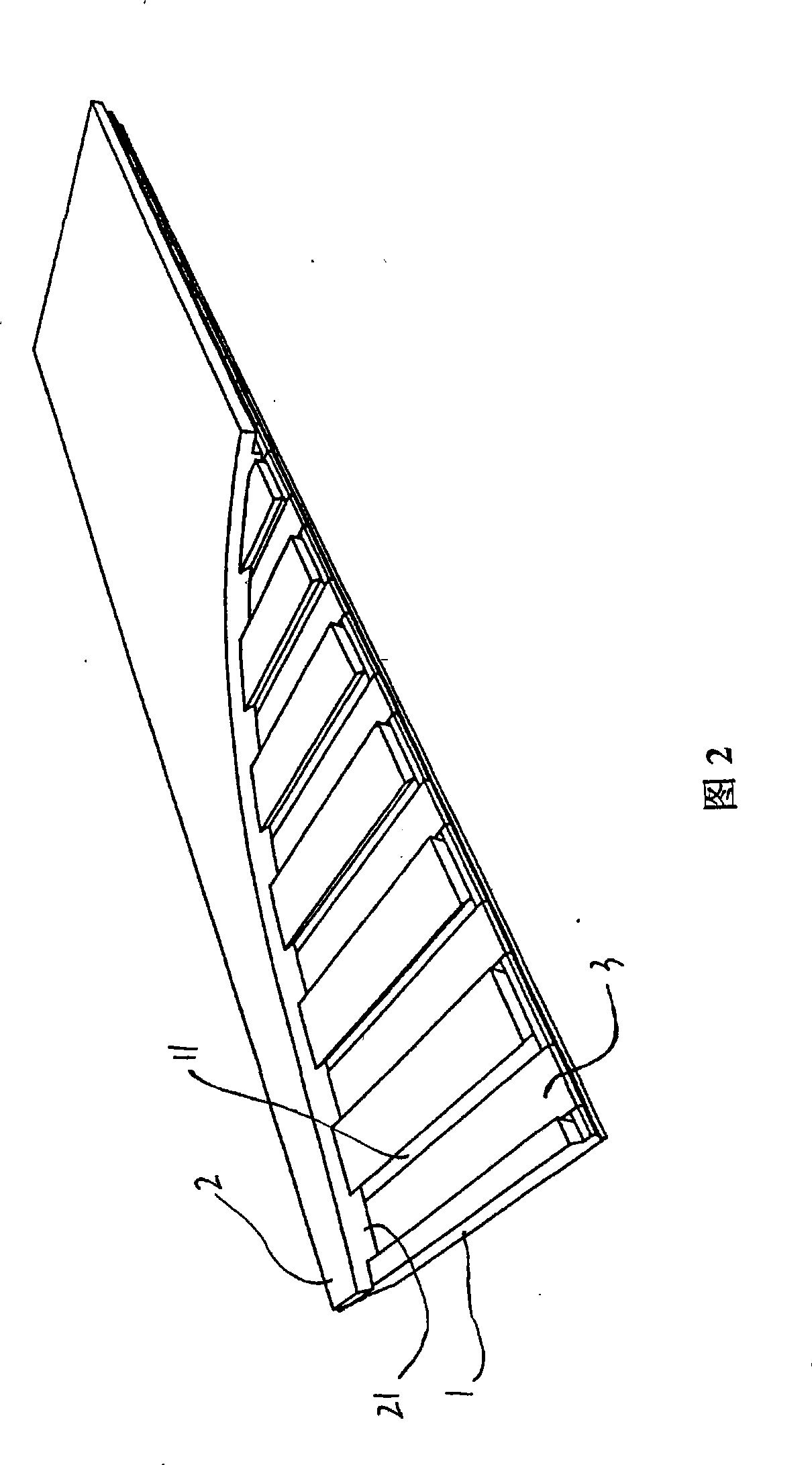

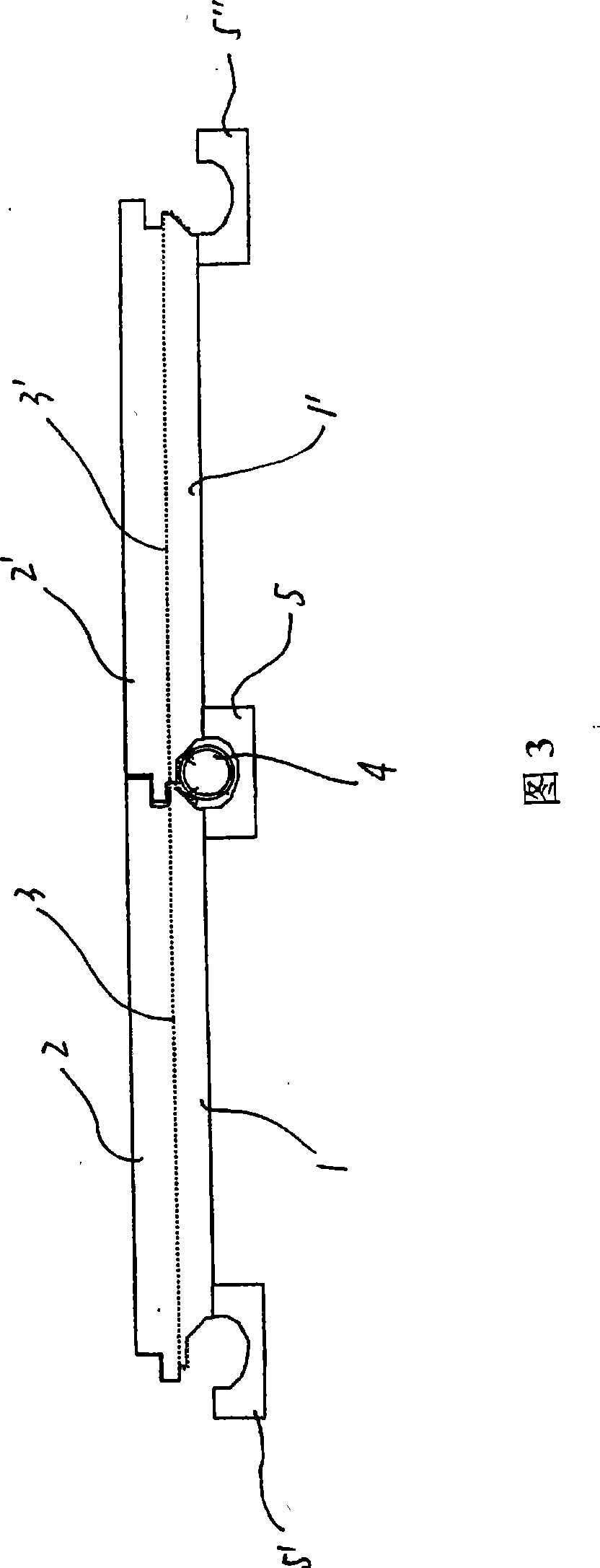

[0023] As shown in Figure 1 and Figure 2, it includes base plate 1, panel 2, floor heating pipes 4, 4', 4'' and keel grooves 5, 5', 5'', and a heat conduction tube is provided between base plate 1 and panel 2 The medium 3, 3', 3'', and the upper surface of the substrate 1 and the lower surface of the panel 2 are respectively provided with several parallel dovetail grooves 11 and corresponding dovetail tenon 21, and the dovetail tenon 21 is correspondingly embedded in the dovetail groove 11; floor heating The upper half of the tubes 4, 4', 4'' are embedded in the two sides of the base plate 1, 1', 1''1''' in the longitudinal direction, and are partially in contact with the heat-conducting medium 3, 3', 3'', floor heating The upper half of the pipes 4, 4', 4'' are embedded in the keel grooves 5, 5', 5''. The heat conduction medium 3, 3', 3'' quickly conducts the heat in the floor heating pipes 4, 4', 4'' and distributes it to various positions of the floor, which can avoid heat ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap