Abradant jet downhole perforation, and kerf multiple fracturing method

A technology of abrasive jet and layered fracturing, which is applied in the fields of slotted layered fracturing, staged fracturing, and downhole perforation. Problems such as segmental fracturing, to achieve the effect of easy assembly and maintenance, avoiding sand stuck problems, and improving fracturing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

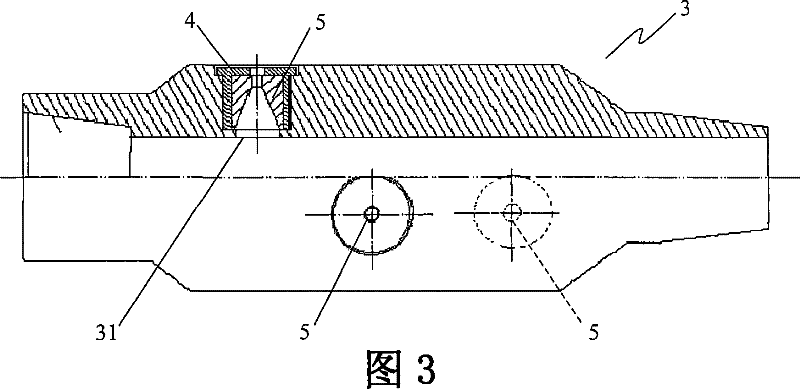

[0022] In order to have a clearer understanding of the technical features, objects and effects of the present invention, the specific embodiments of the present invention will now be described with reference to the accompanying drawings.

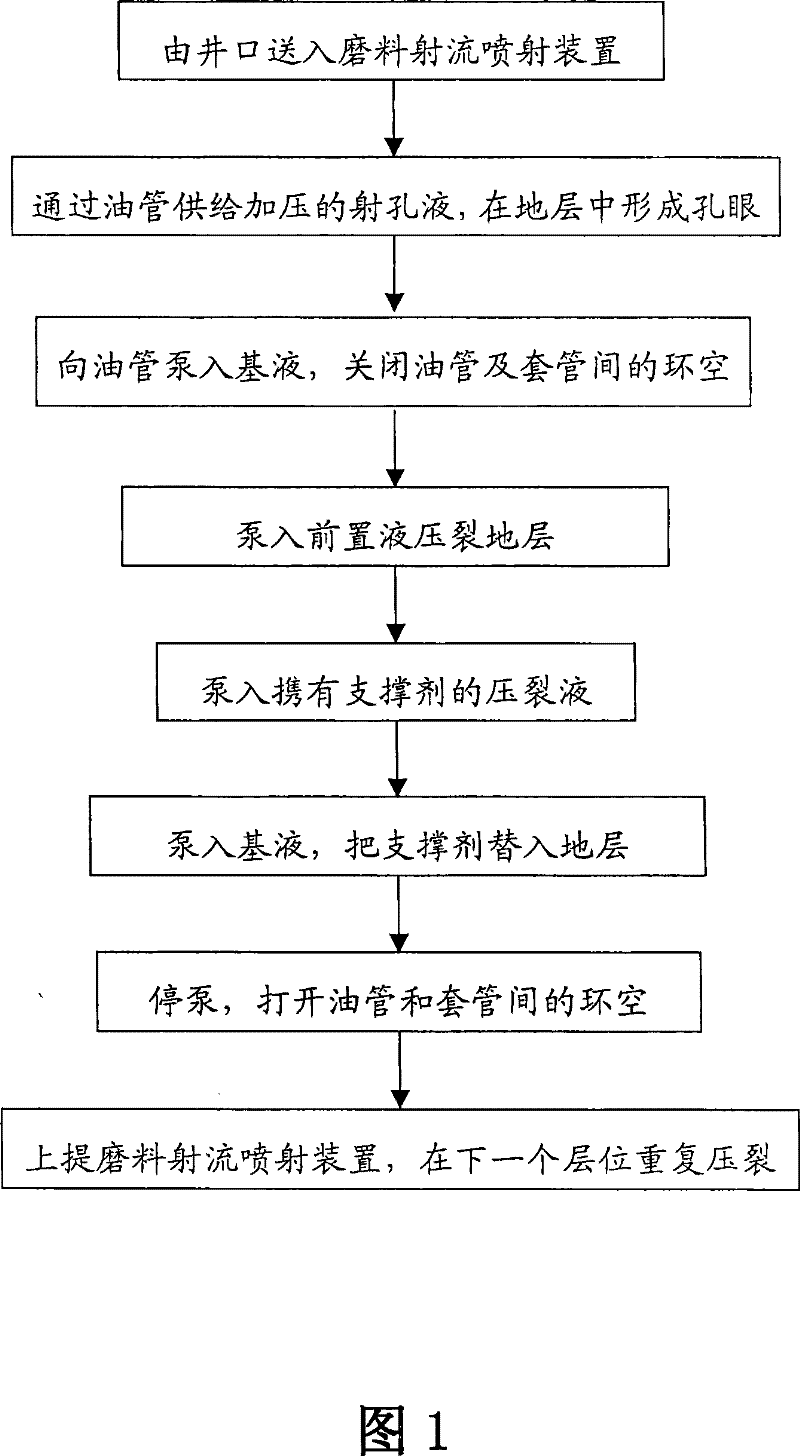

[0023] See figure 1 , the abrasive jet downhole perforation, slit and layered fracturing method of the present invention comprises the following steps:

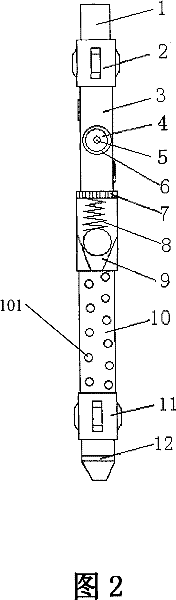

[0024] (1) Pass the oil pipe to figure 2 The abrasive jet injection device shown is fed into the well at a specified level;

[0025] (2) Supply pressurized perforating fluid to the abrasive jet injection device through oil pipe 1, and from the nozzle of the injection device to the sidewall of the casing and the formation at high speed (for example, the outlet velocity of the nozzle is not lower than 230 m / s) injecting the perforating fluid to form perforations in the formation;

[0026] (3) pumping fracturing fluid into the hole to form fracturing fractures in the formation in the hole;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com