Device and method for detecting rotary position of to-and-fro piston engine crankshaft

A technology of rotating position and reciprocating piston, which is applied in the direction of engine control, machine/engine, mechanical equipment, etc., and can solve problems such as indirect detection distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

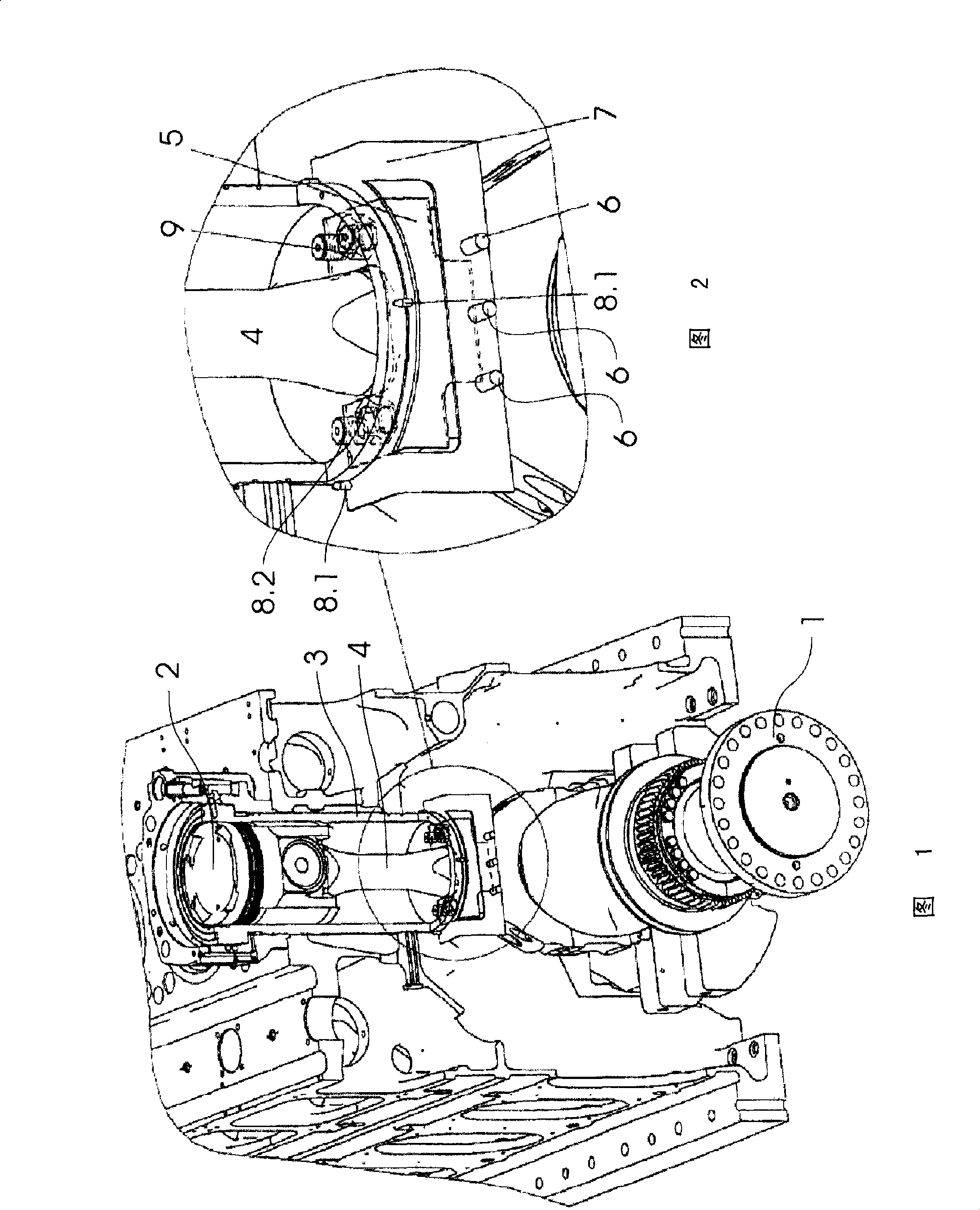

[0040] figure 1 A perspective partial sectional view, with some components removed for clarity, shows a reciprocating piston engine with a crankshaft 1 and a piston 2 movable in a cylinder 3 . The piston is connected to the crankshaft 1 through the crank 4, so that the piston 2 moves up and down in the cylinder when the crankshaft rotates. If piston 2 occupies its farthest position from crankshaft 1 in cylinder 3, then crankshaft 1 is at its figure 1 at the top dead center shown.

[0041] The reciprocating piston engine includes additional cylinders (not shown) in which corresponding pistons move, wherein the pistons figure 1 The pistons shown in are coupled to the crankshaft 1 offset in such a way that they each occupy their position furthest away from the crankshaft 1 when the crankshaft 1 is in different rotational positions. In this respect, the crankshaft 1 has a top dead center for each cylinder, which can be determined according to the invention by arranging the devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com