8-shaped self-bearing aerial fiber cable catenary dissector

An overhead optical cable, self-supporting technology, applied in the direction of optical fiber/cable installation, fiber mechanical structure, etc., can solve the problems of difficult stripping length of 0.5 meters, high strength, difficult manual cutting, etc., to facilitate outdoor construction use and work. The effect of improved efficiency and high peeling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

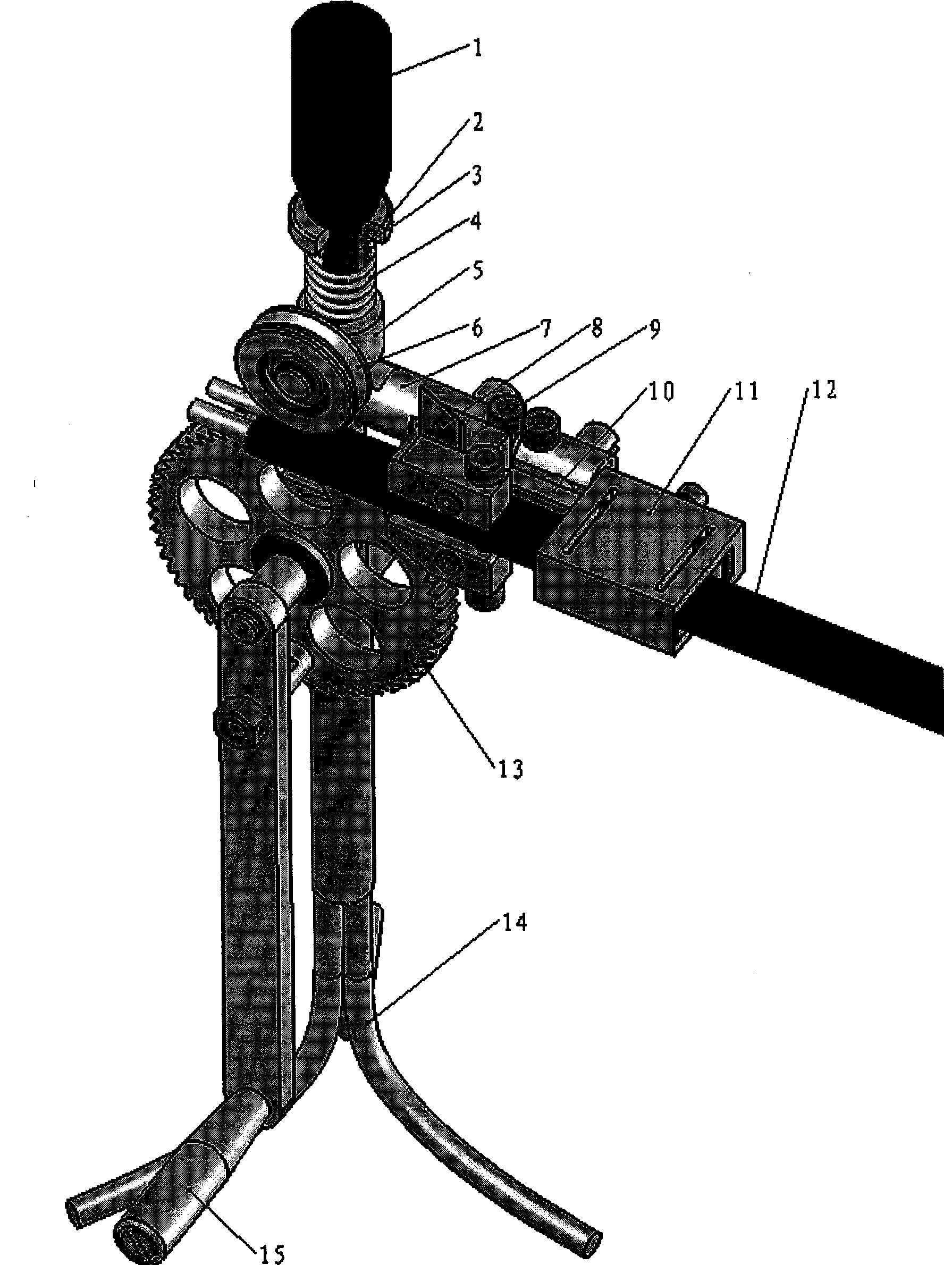

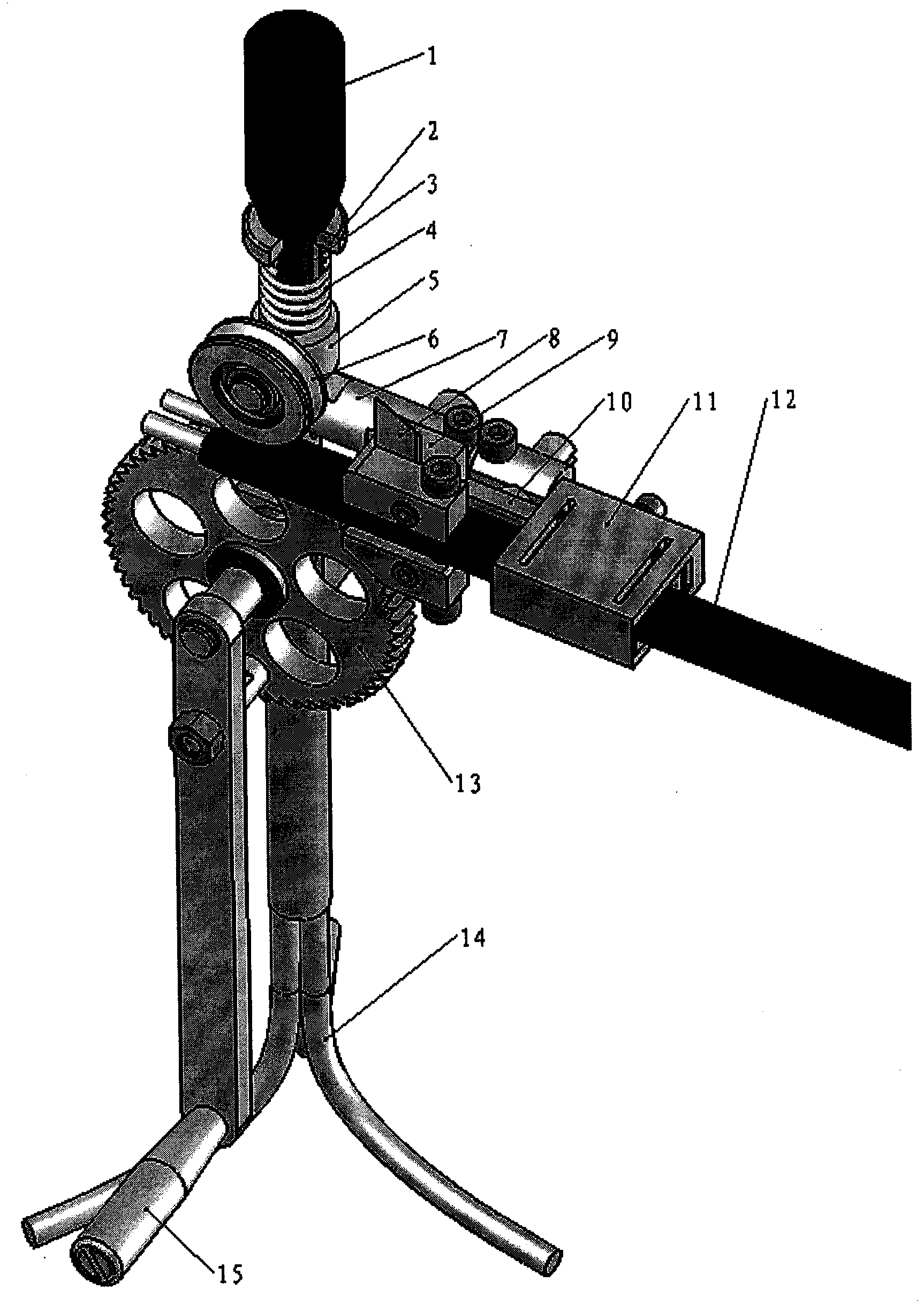

[0013] The technical scheme adopted by the present invention is: a longitudinal axis and a horizontal axis installed on the longitudinal axis constitute the main supporting structure of the "8"-shaped self-supporting overhead optical cable suspension wire stripper. The parts mechanically connected with the vertical axis are as follows from bottom to top: supporting base, toothed cutter wheel (including auxiliary parts such as driving handle and copper bushing installed on it), horizontal axis (including from right to left on the horizontal axis) Positioning mechanism and blade clamp mechanism installed successively), compression slide shaft (comprising the V-shaped compression wheel installed on it), compression spring, compression spring adjustment nut, top handle. The compression slide shaft can freely slide up and down along the longitudinal axis, adjust the compression spring adjustment nut, and the spring pressure acts on the compression slide shaft, so that the V-shaped c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com