Endoscope washing and disinfecting apparatus and leak detection method performed by the apparatus

A technology for cleaning and disinfecting endoscopes, applied in the direction of endoscopes, using liquid/vacuum for liquid tightness measurement, disinfection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

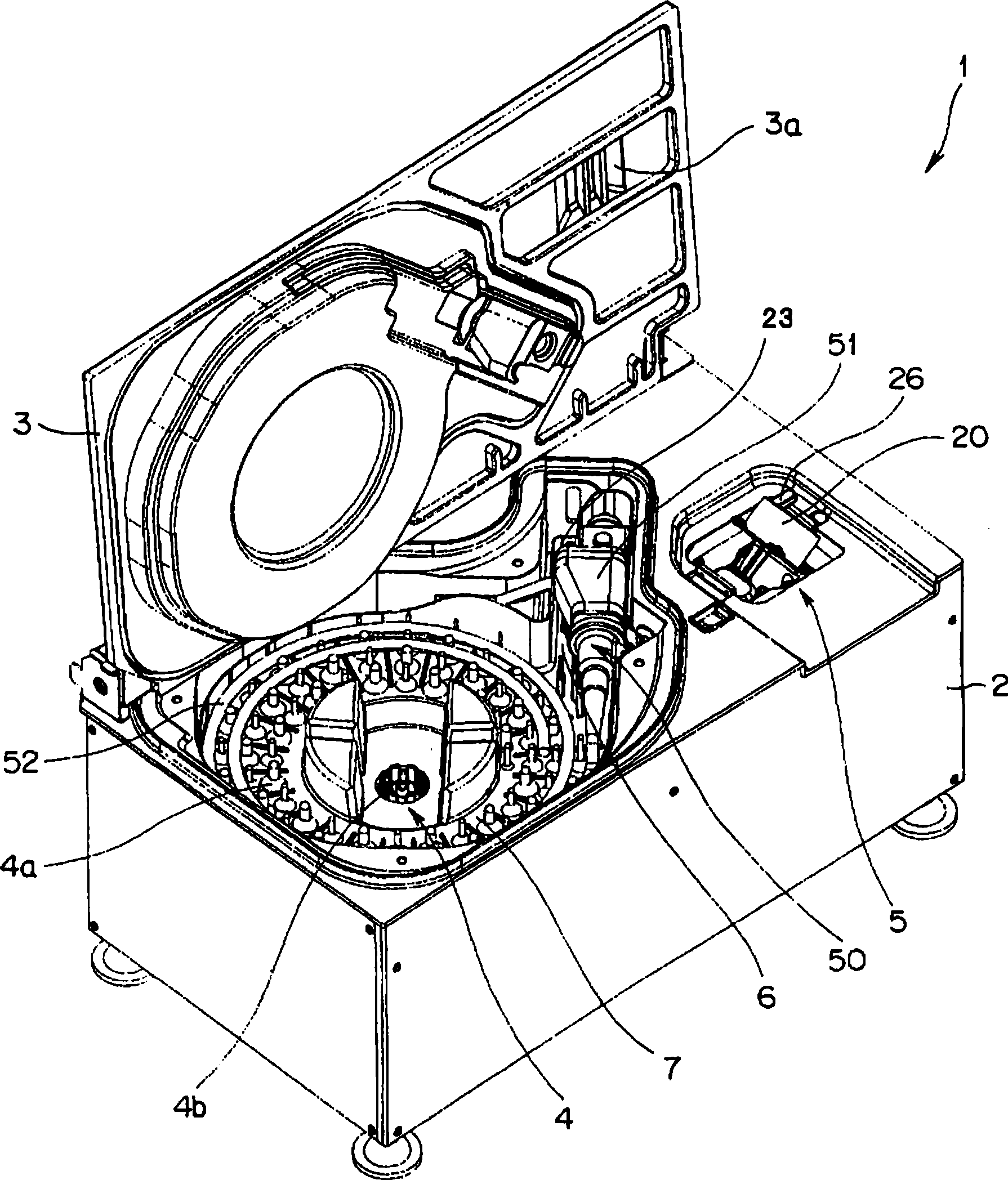

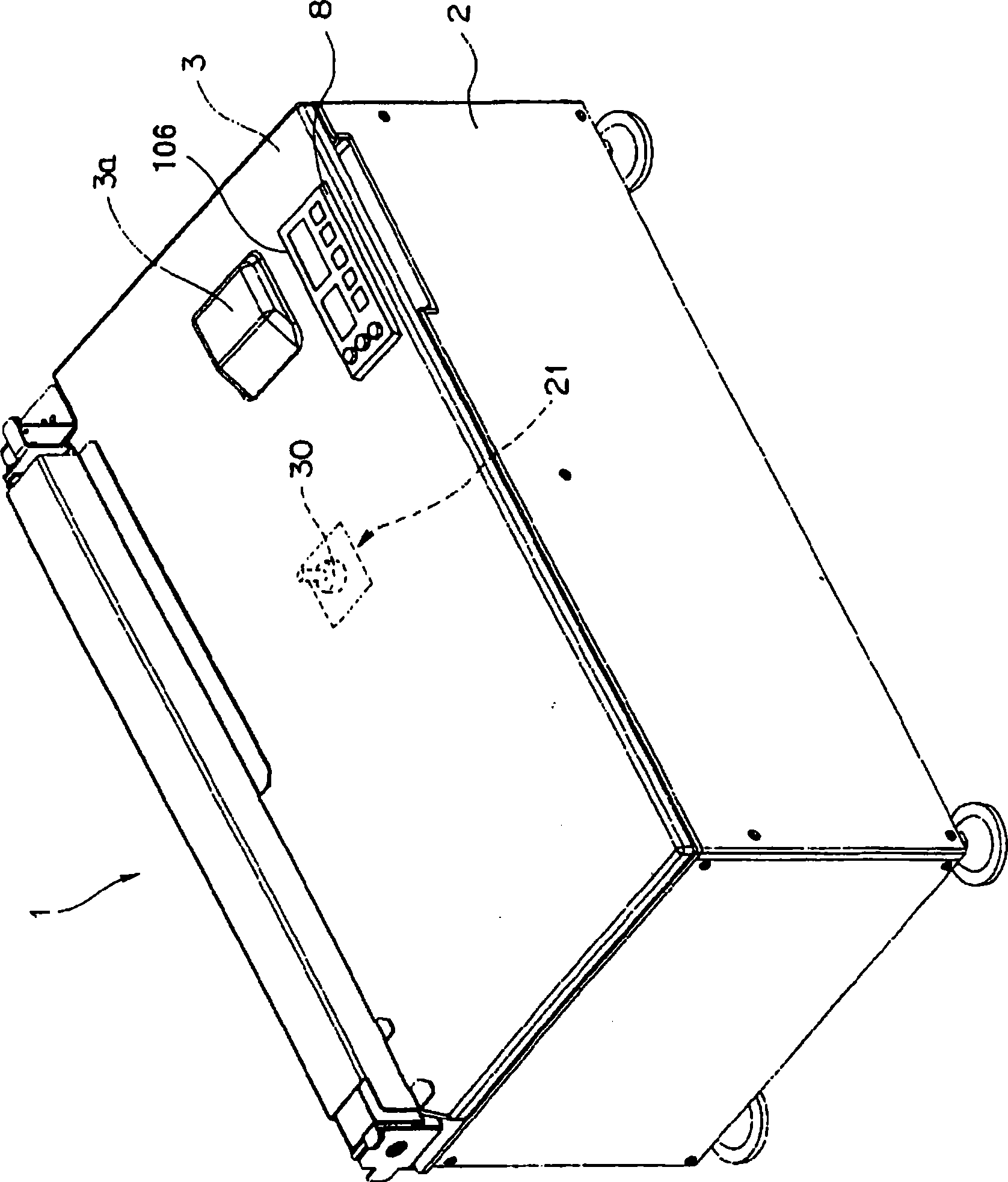

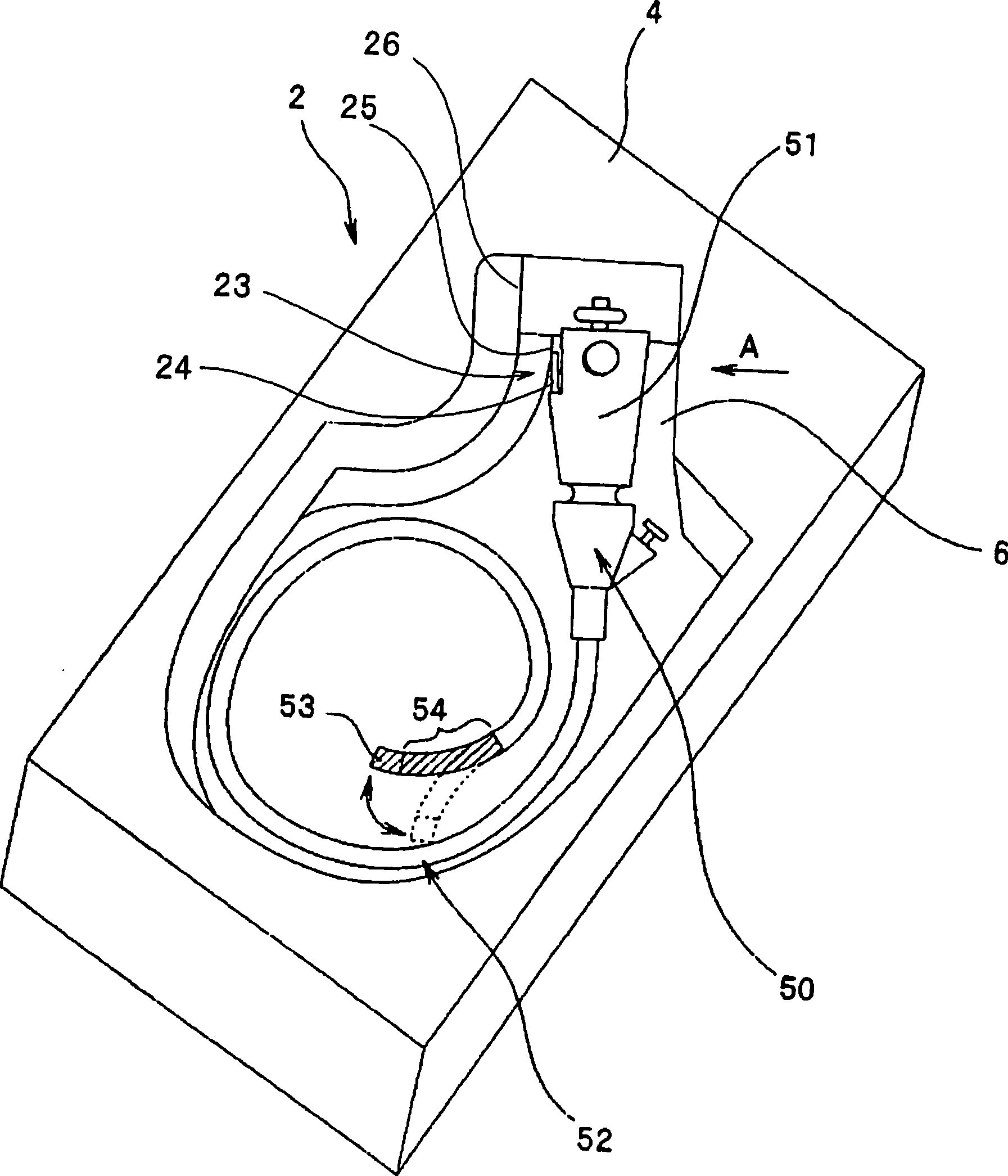

[0027] Figure 1 to Figure 8 represents an embodiment of the present invention, figure 1 It is a perspective view showing the appearance of the cleaning device of this embodiment in a state where the top cover is opened, figure 2 It is a perspective view showing the appearance of the cleaning device of this embodiment in a state where the top cover is closed, image 3 It is a perspective view showing a state in which a grip portion of an endoscope is connected to a connection portion of the cleaning device according to the present embodiment and the endoscope is accommodated in a cleaning tank, Figure 4 is used to illustrate from image 3 A cross-sectional view of the structure of the front-end driving part, the connecting part, and the gripping part of the endoscope connected to the connecting part in the main body of the device when viewed in the direction of arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com