Apparatus and method for separating mixed materials of different flowability

A technology of mixing materials and fluidity, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve problems such as large space requirements, additional manufacturing costs, low output, etc., to achieve reduced contact pressure, reduced wear, The effect of fast and easy to and fro movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

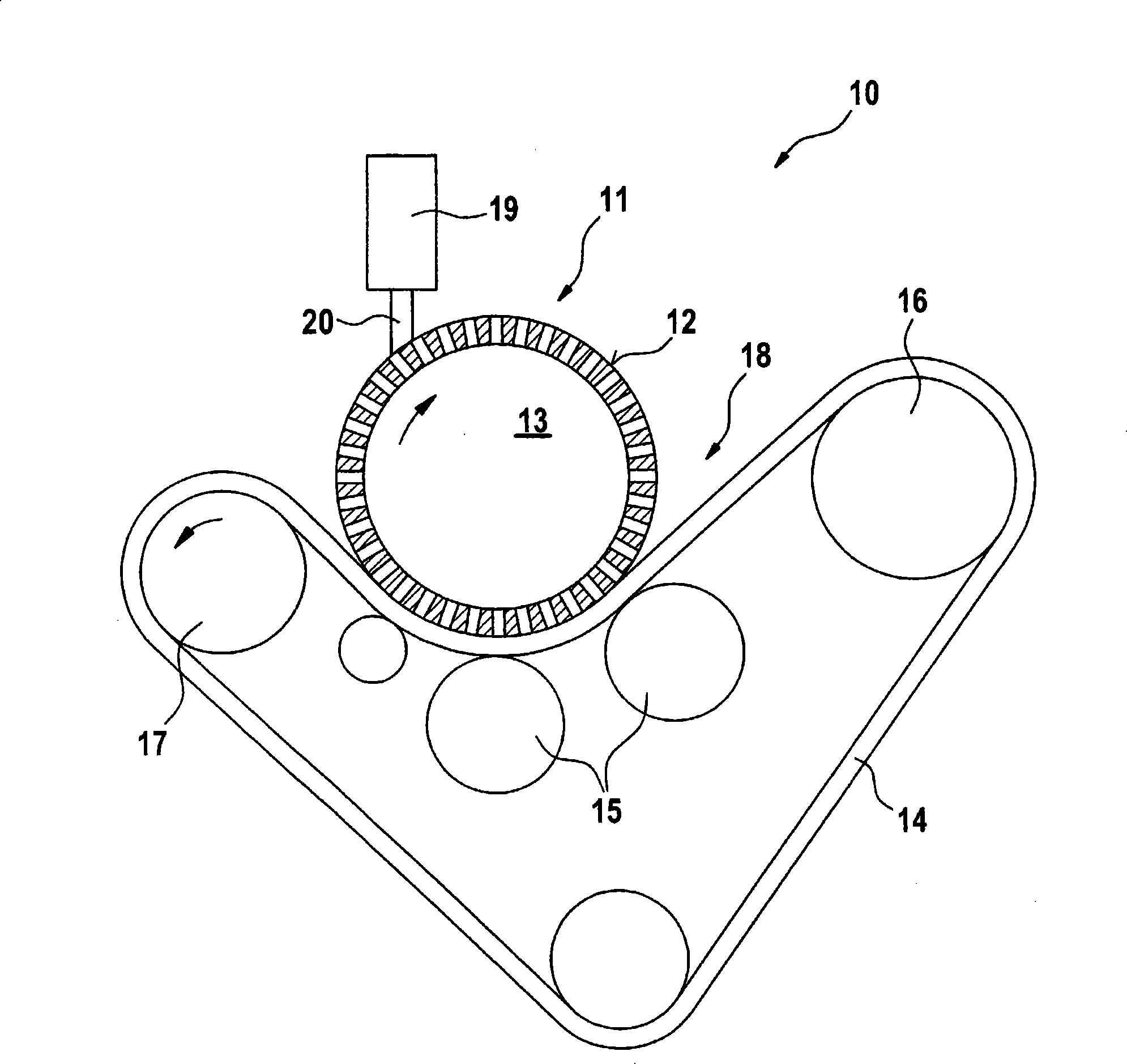

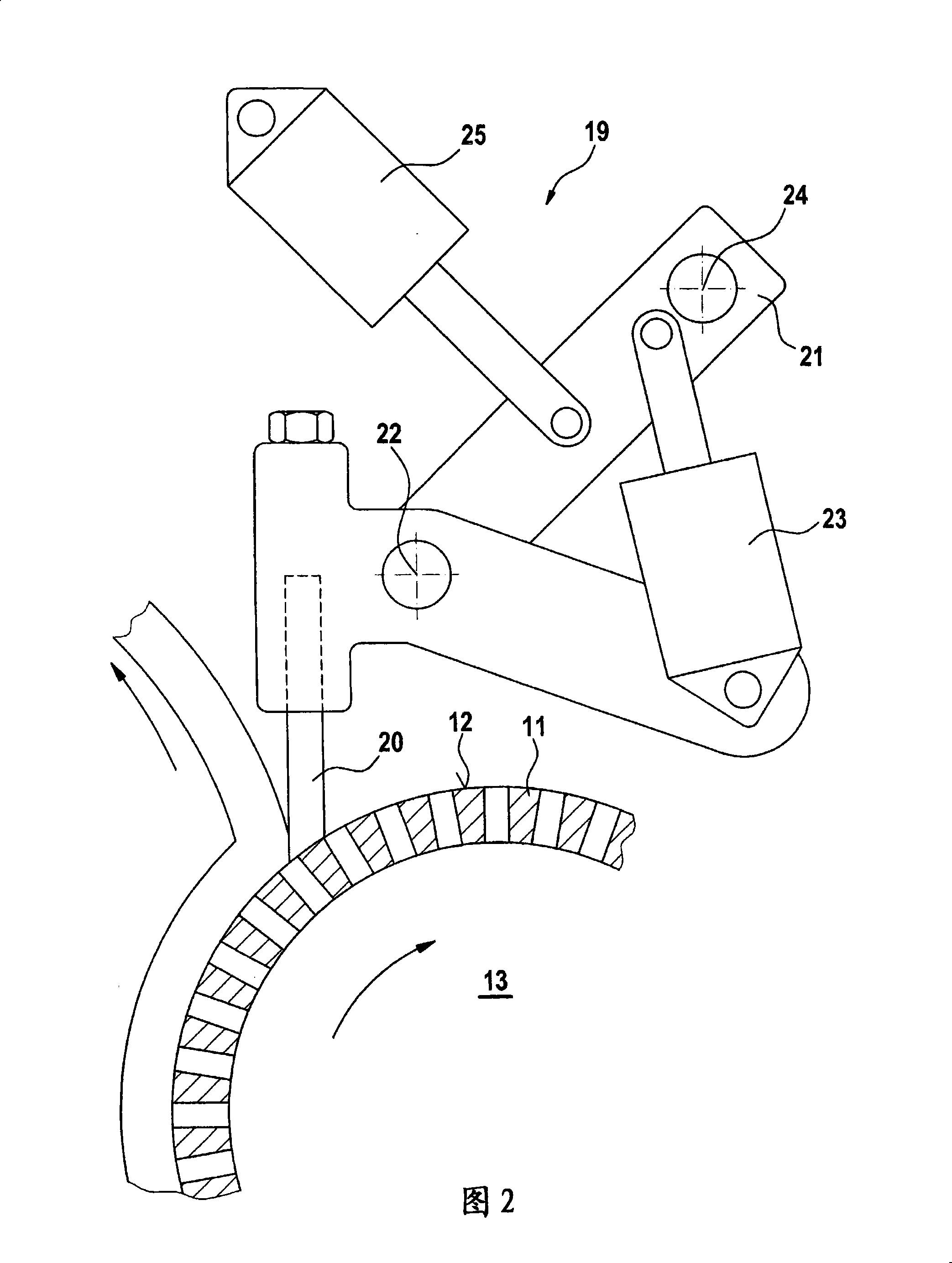

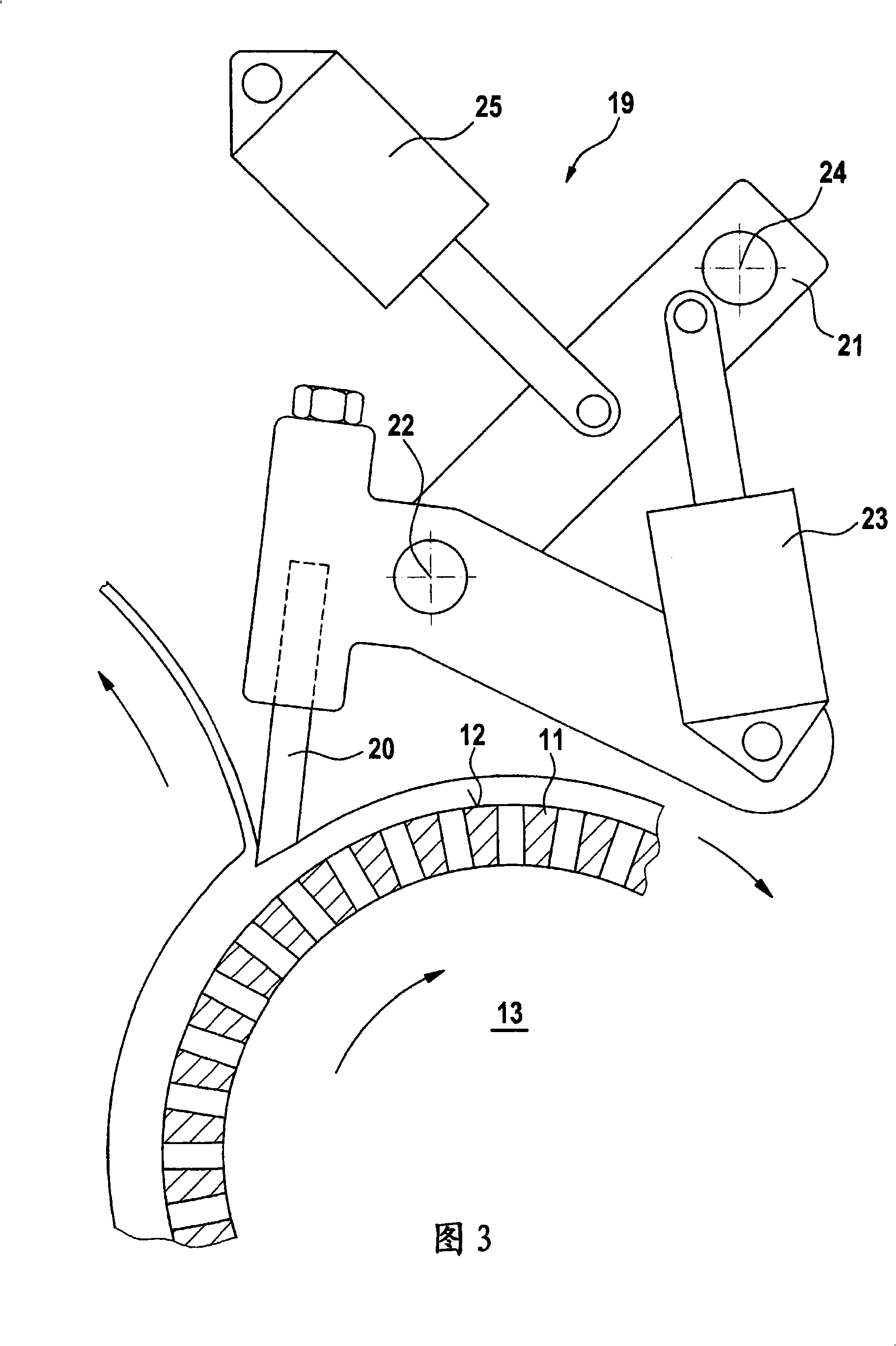

[0017] The device shown in the figure is used for separating mixed materials of different fluidity, such as for separating the pulp of fruit from the core in the case of dates or film packaging from cheese slices in the case of dates. However, the device and method can also be used for the treatment of animal bodies and the like.

[0018] figure 1 The apparatus 10 shown in , for separating materials mixed with each other comprises a housing or frame (not shown) in or on which a hollow drum 11 is rotatably mounted. The hollow drum 11 has a perforated peripheral surface 12 . Inside the hollow drum 11 is formed a lumen 13 from which extruded / separated material, or its more flowable constituents, which is pressed through said holes, can be entrained. Part of the circumference of the rotationally driven hollow drum 11 is surrounded by a preferably annular pressure belt 14 made of an elastic material such as rubber, polyurethane or the like. In order to avoid products entering th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com