Ultrasonic material level meter

A level meter and ultrasonic technology, applied in the field of ultrasonic measuring devices, can solve problems such as low measurement accuracy, unstable measurement, failure to remove interference waves, etc., and achieve the effects of accurate echo data, noise suppression, and high transmission power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

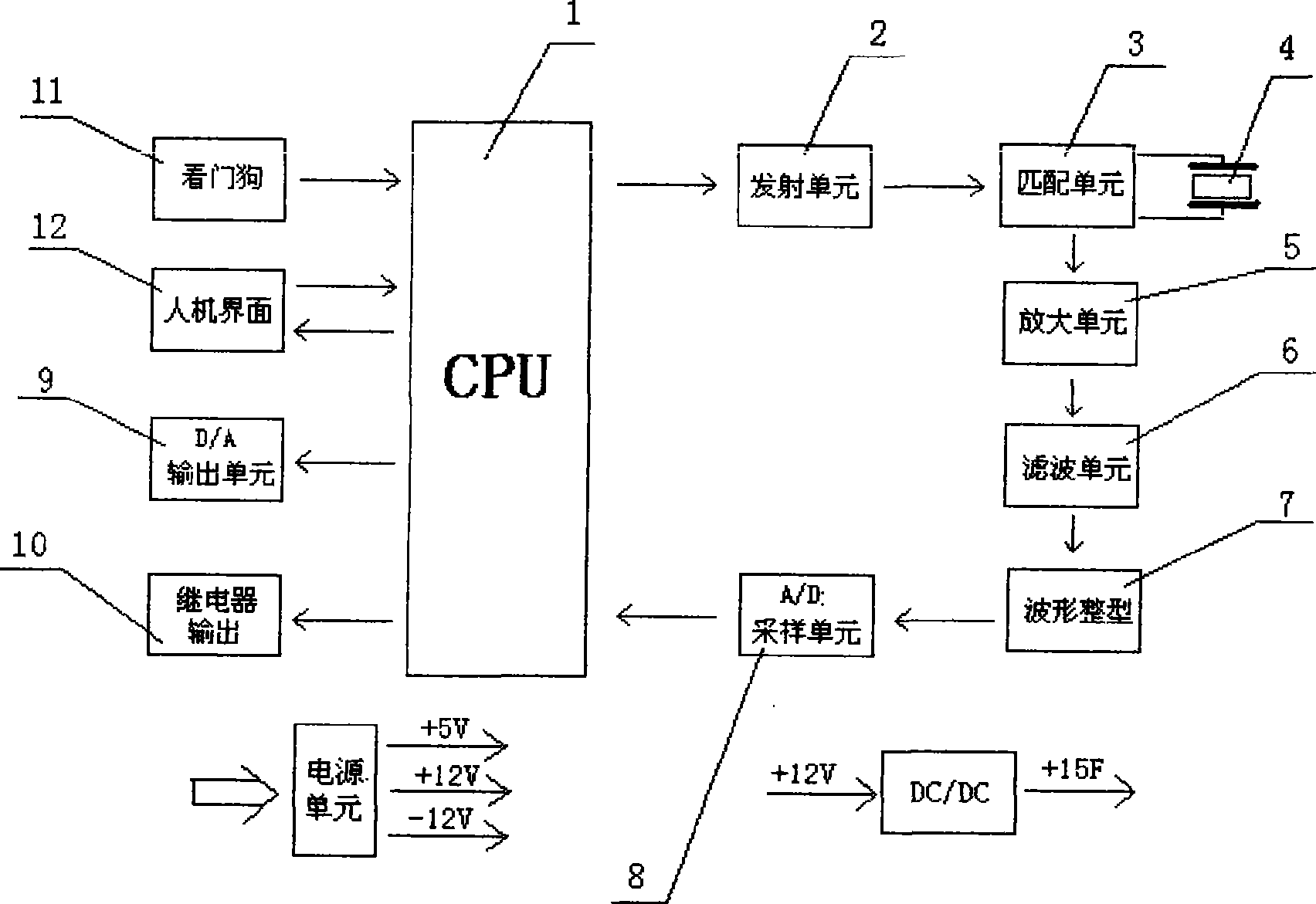

[0011] Specific embodiments: The structure and working principle of the ultrasonic level gauge will be described in detail in conjunction with the accompanying drawings.

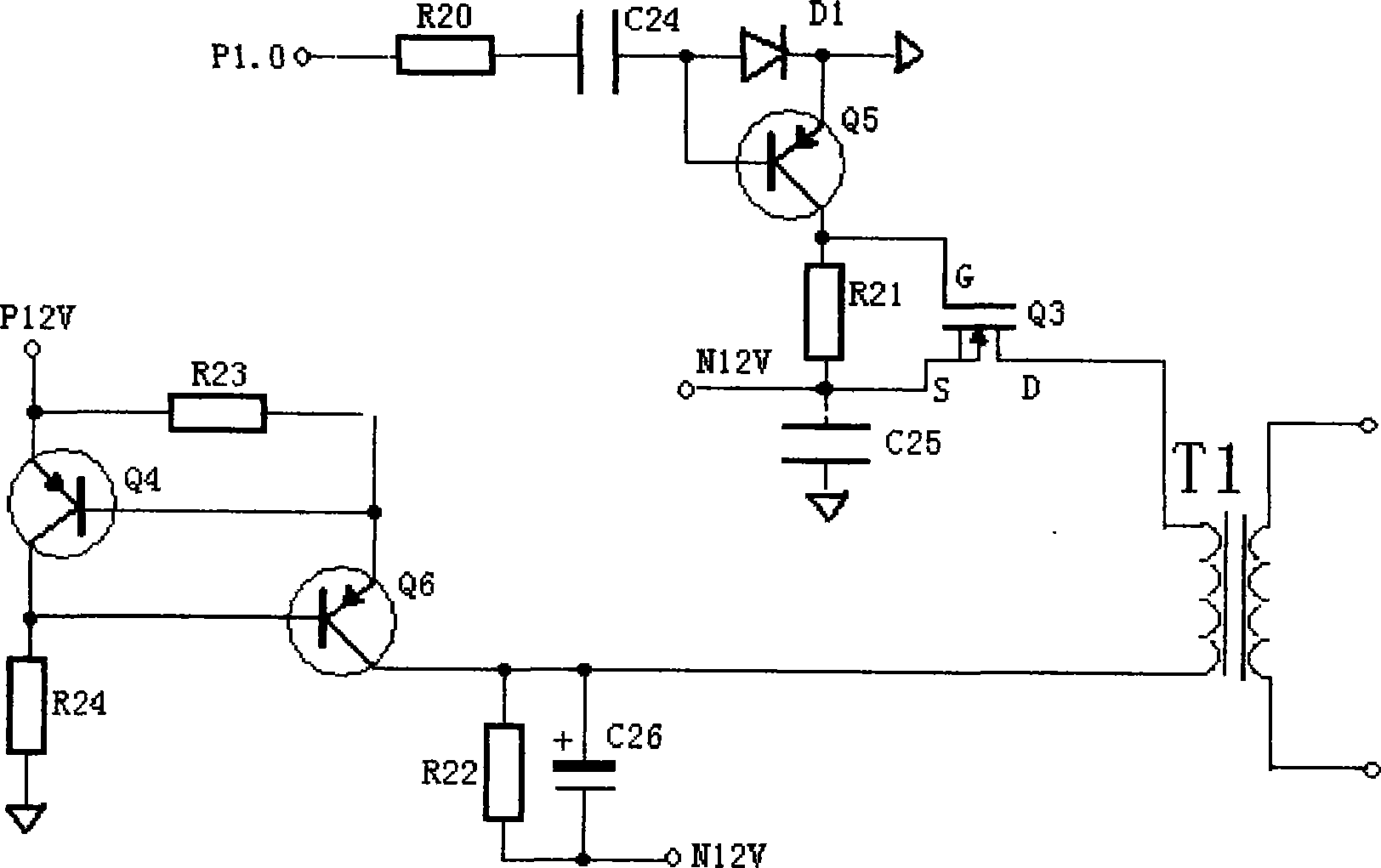

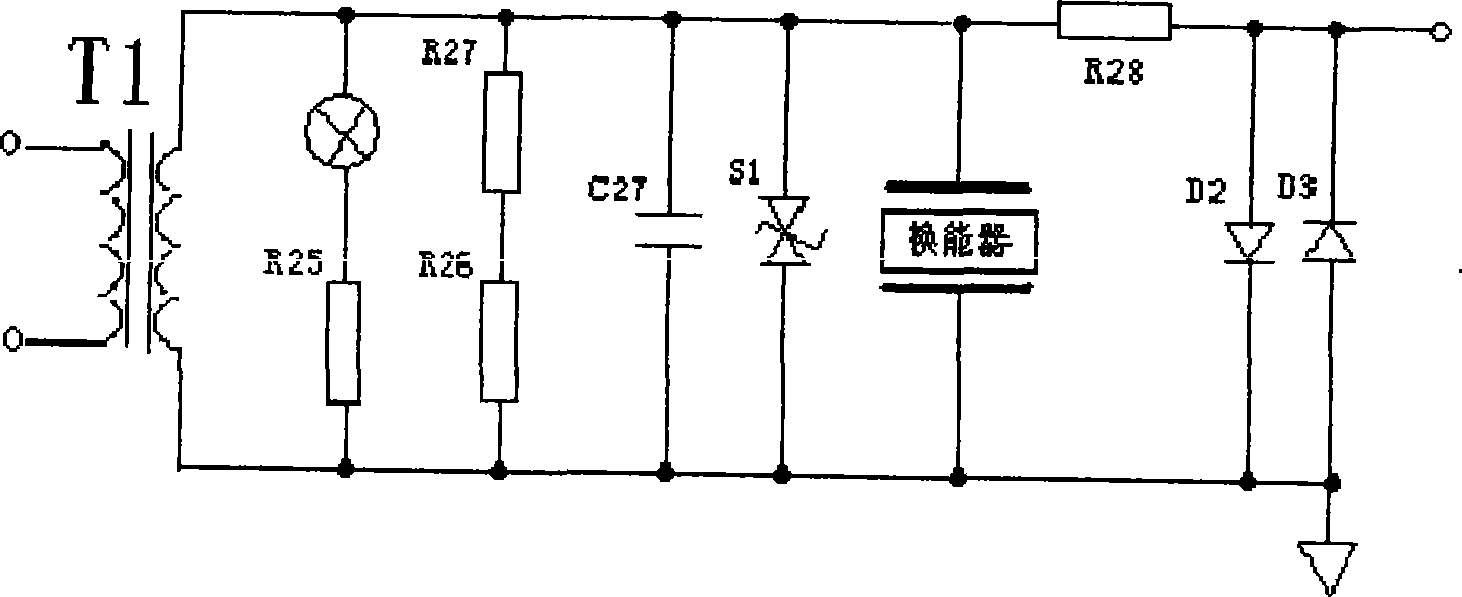

[0012] An ultrasonic level gauge is composed of a host and a transducer, figure 1 It is the principle block diagram of the ultrasonic level meter of the present invention. The CUSS200 ultrasonic sensor of SENSE Company is housed in the transducer 4 shell, and its optimal operating frequency is 41kHz, and the detection range can reach 20 meters. The outer shell of the transducer is plexiglass , filled with polyester, the sound energy window is epoxy resin reinforced plexiglass, which is characterized by no interference, a commercially available temperature sensor is installed in the housing, and the central processing unit (CPU) 1 of the ultrasonic level gauge host is Philhps The product is equipped with ultrasonic receiving and sending timing control program, transmitting power control program, measurement d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com