Radiating plate for semiconductor package and electroplating method therefor

A technology for heat sinks and semiconductors, which is applied in the directions of semiconductor devices, semiconductor/solid-state device manufacturing, and semiconductor/solid-state device components, etc., can solve problems such as weakening the connection force between the substrate 200 and the foot portion 170 , etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0053] will refer to Figure 3A to Figure 3E The first embodiment will be explained.

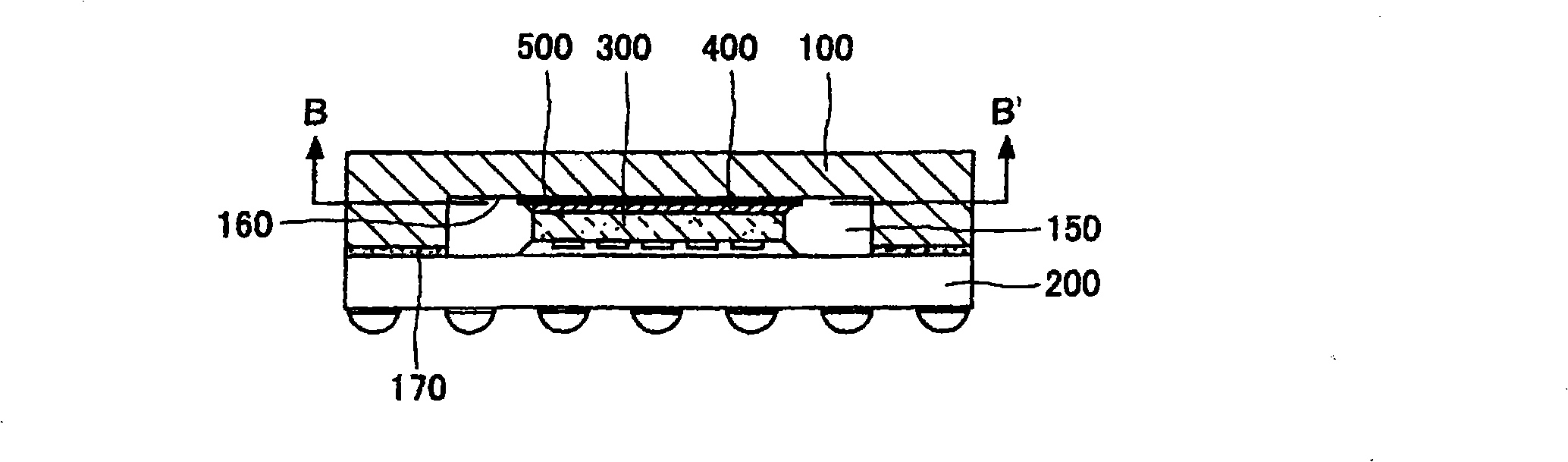

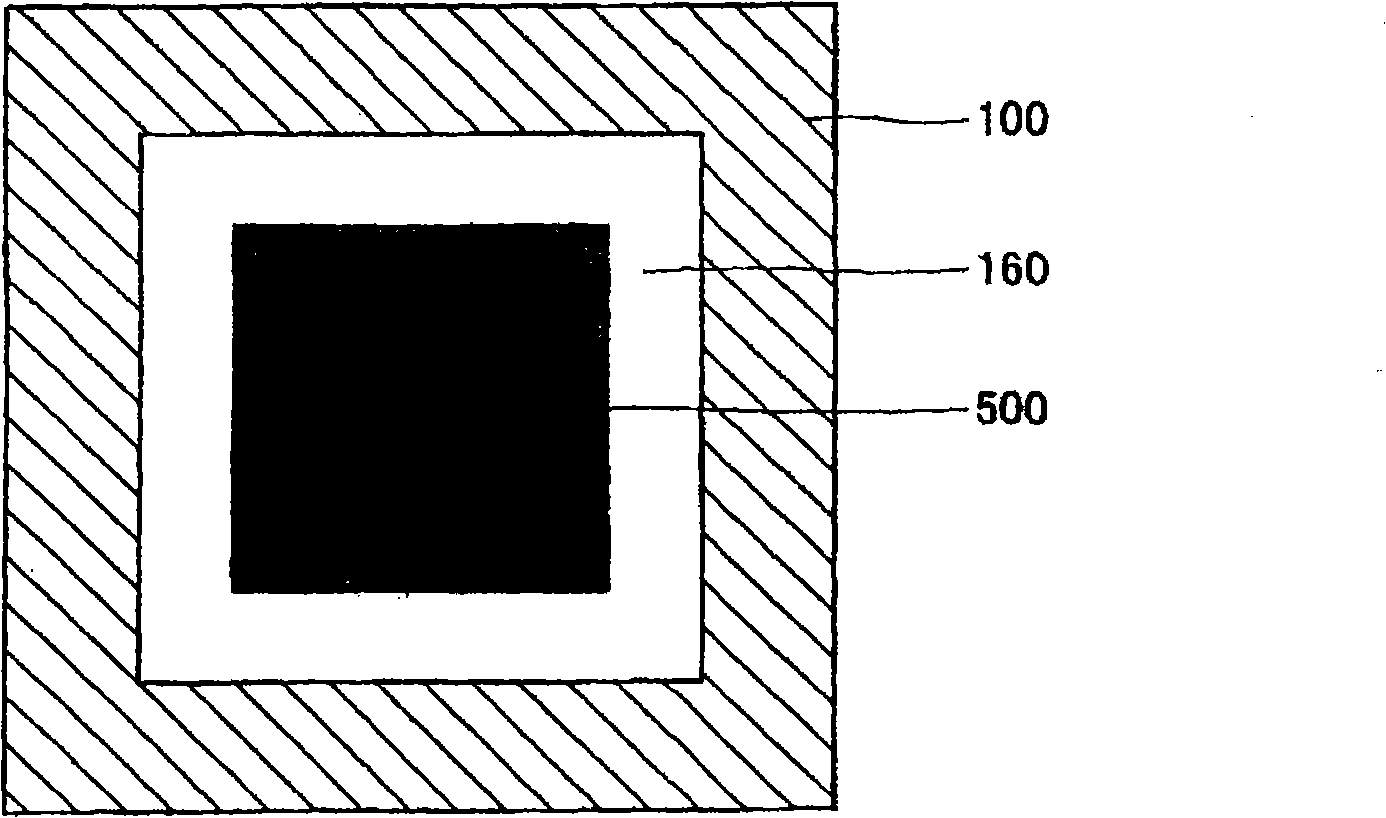

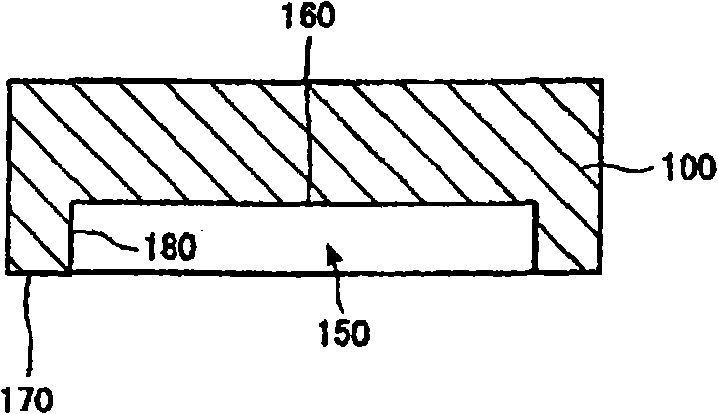

[0054] Such as Figure 3E As shown, the cooling plate 10 according to the first embodiment is square when viewed from a plan view, and its overall shape is roughly a cuboid. Such as Figure 3A As shown, a concave portion 15 is provided on the central portion of the inner bottom surface of the cooling plate 10, and a foot portion 17 is also provided on the peripheral portion of the bottom surface. A stepped portion 18a which will constitute a mask region 19a (discussed below) is provided on the entire periphery of the inner wall portion 18 formed between the bottom surface of the foot portion 17 and the inner bottom surface 16 . The stepped portion 18 a is provided on the inner wall portion 18 and arranged between the first inner wall forming the outer periphery of the inner bottom surface 16 and the second inner wall forming the inner periphery of the foot portion 17 . As shown in the to...

no. 2 example

[0070] Next, refer to Figure 4A to Figure 4E A second embodiment of the present invention is explained.

[0071] The heat dissipation plate 10 according to the second embodiment has a square shape when viewed from a top view, and its overall shape is substantially a cuboid. Such as Figure 4A As shown, a recess 15 is provided in the central portion of the bottom surface of the heat sink 10, and a foot portion 17 is also provided on the peripheral portion of the bottom surface. A sloped portion 18b forming a mask area 19a (discussed below) is provided on the entire periphery of the inner wall portion 18 disposed between the bottom surface of the foot portion 17 and the inner bottom surface 16 . The inclined portion 18b is inclined such that the opening area of the above-described inclined portion 18b gradually becomes larger from the inner bottom surface 16 side toward the foot portion 17 side.

[0072] Metals having excellent thermal conductivity such as aluminum and cop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com