Light source deviceLight source die set and method for manufacturing the light source device

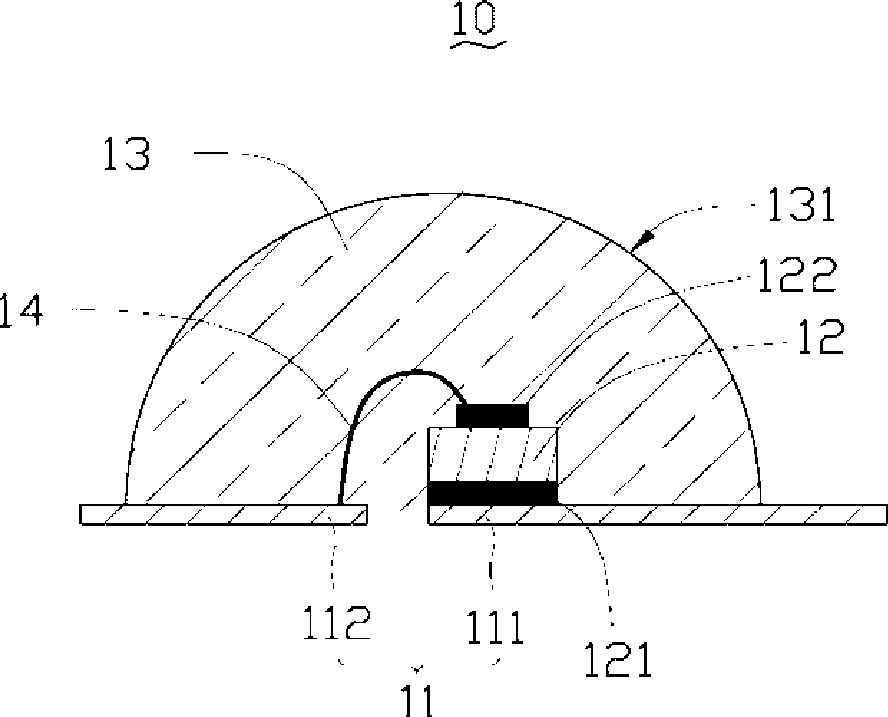

A technology of a light source device and a light source module, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, electric solid-state devices, etc., can solve the problems of limited application fields and small irradiation range of the light source device 10, and achieve a large irradiation range and simple manufacturing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings.

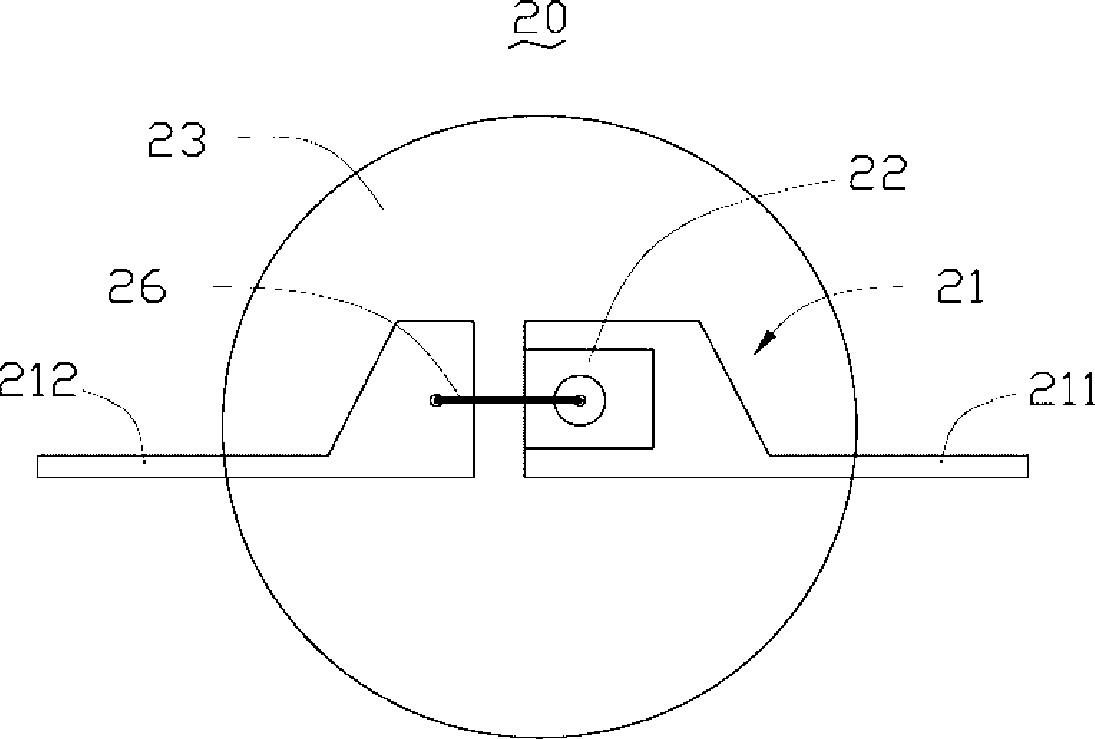

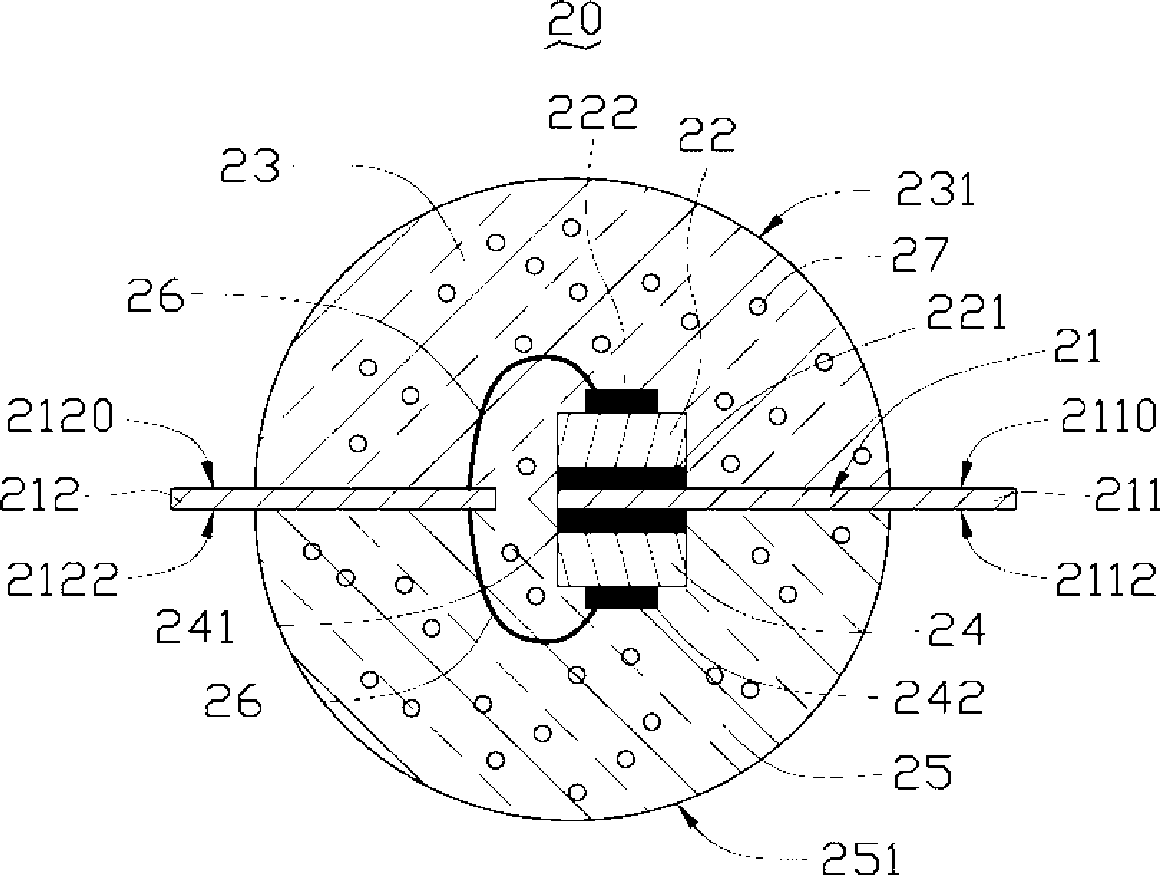

[0020] See figure 2 and image 3 The light source device 20 provided by the first embodiment of the present invention includes a conductive frame 21 , a first solid state light emitting chip 22 , a first package 23 , a second solid state light emitting chip 24 and a second package 25 . The following will be described by taking the first solid-state light-emitting chip 22 and the second solid-state light-emitting chip 24 as light-emitting diode chips as an example.

[0021] The conductive frame 21 includes a first electrode 211 and a second electrode 212 . The first electrode 211 and the second electrode 212 are used for connecting with an external power source. The first electrode 211 includes a first surface 2110 and a second surface 2112 opposite to the first surface 2110, the second electrode 212 includes a first surface 2120 and a second surface 2122,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com