Sputtering apparatus

A sputtering equipment and equipment technology, applied in the directions of sputtering plating, ion implantation plating, coating, etc., can solve the problem that the inflow or outflow of sputtered particles cannot be prevented, and achieve the effect of preventing mutual contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

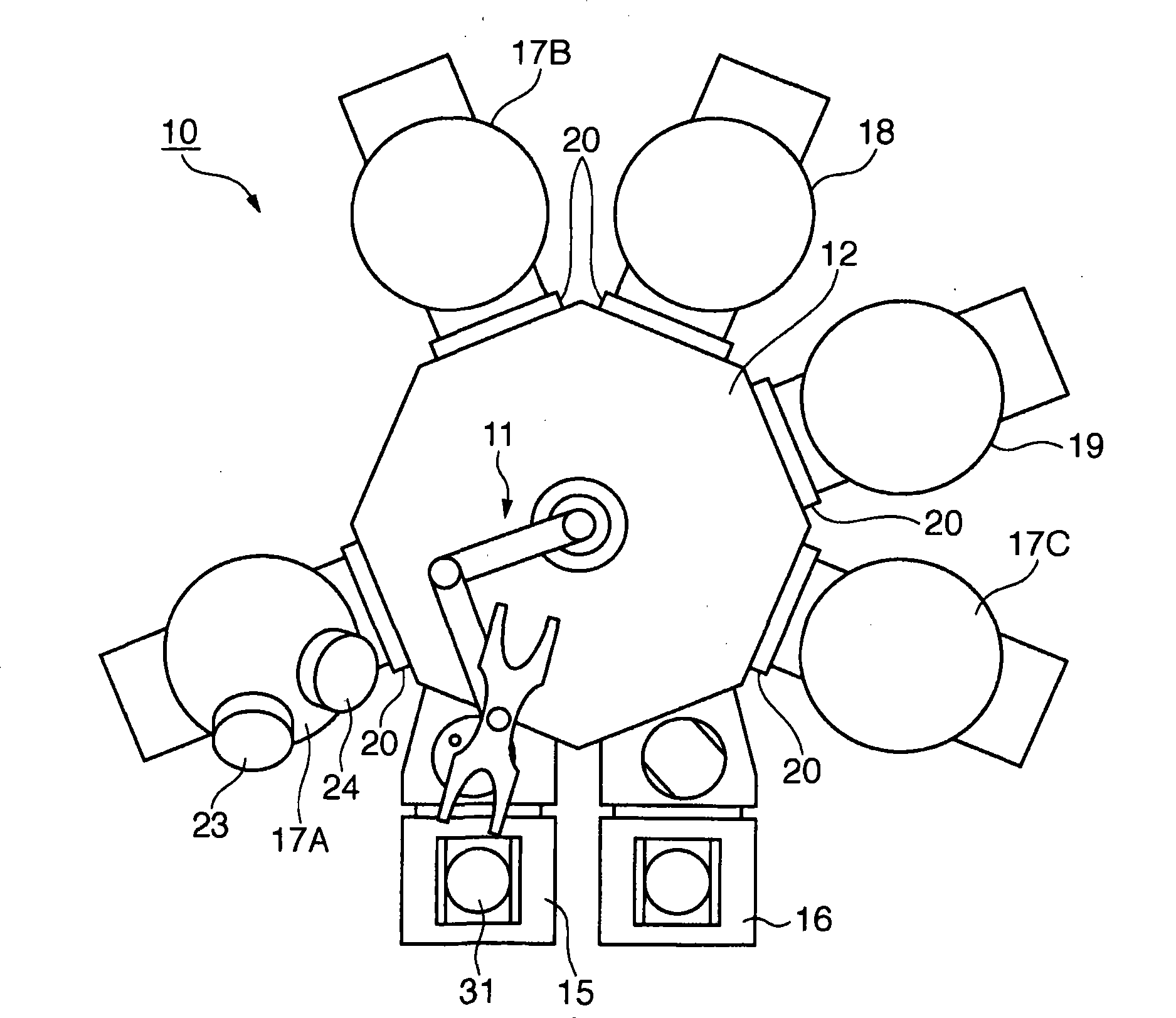

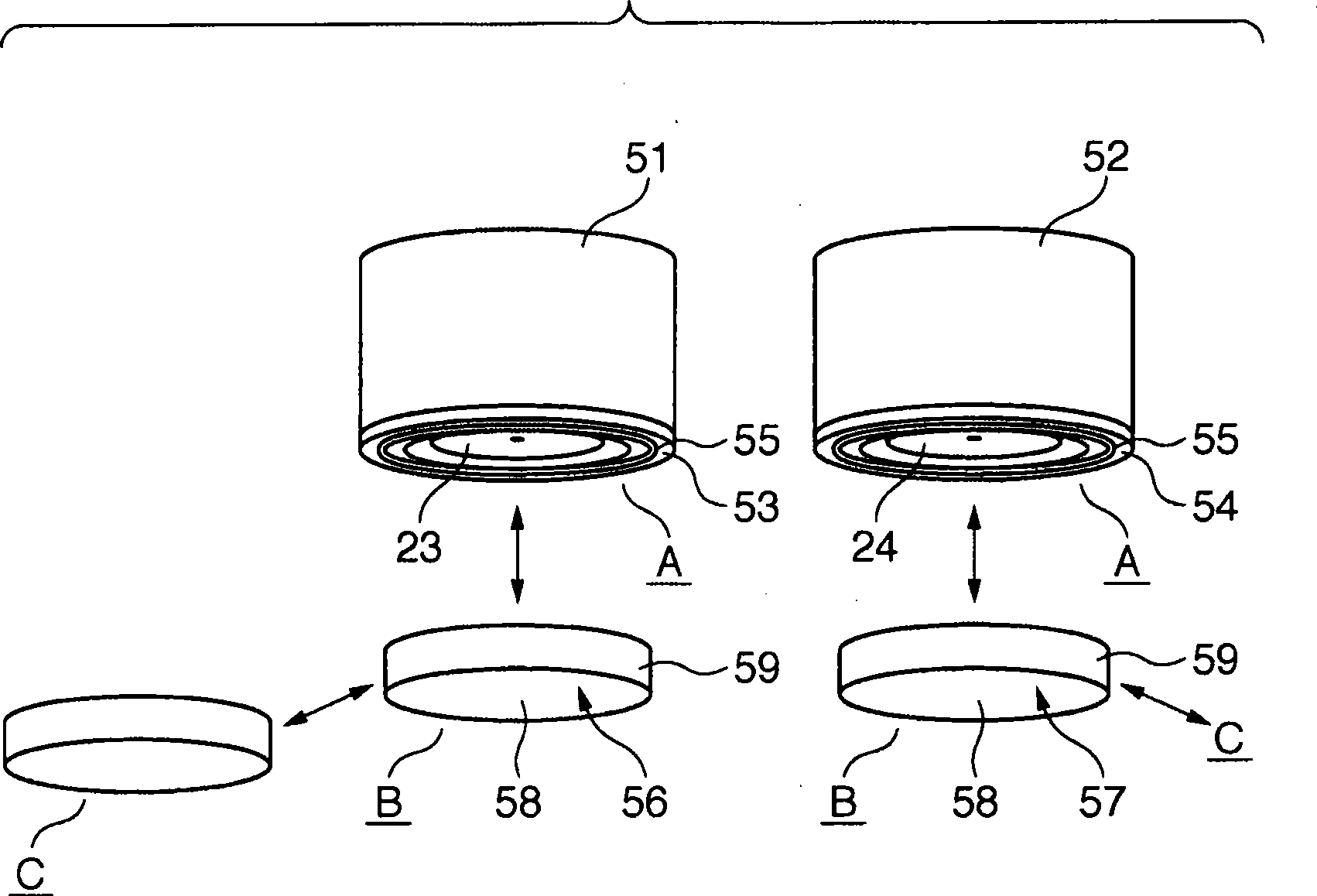

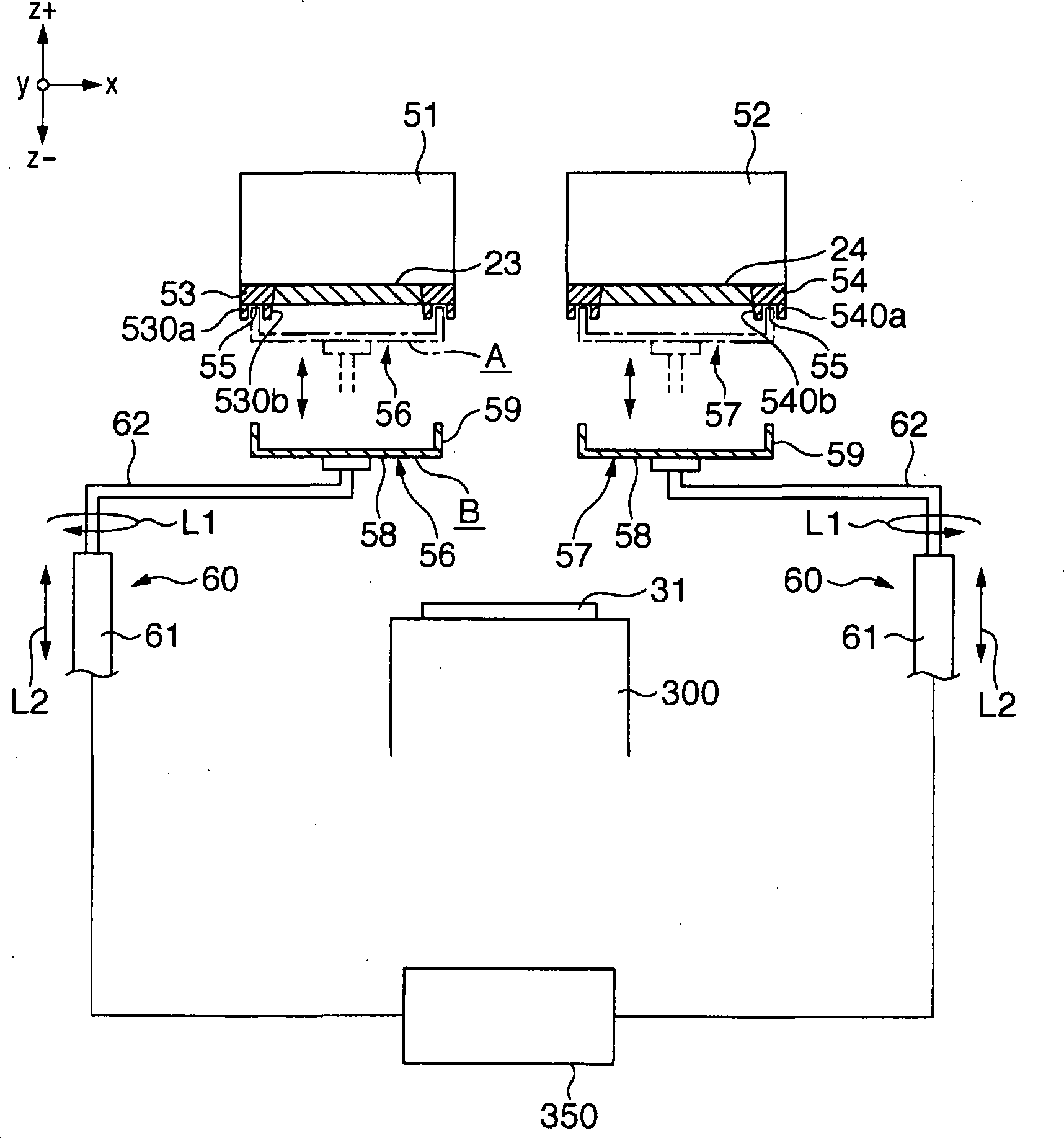

[0022] will refer to figure 1 The sputtering apparatus according to the present embodiment is explained. For example, the sputtering apparatus is an apparatus for manufacturing an optical multilayer interference filter. It should be noted that the sputtering device is not limited to devices having this arrangement. figure 1 A schematic arrangement of the internal mechanism of the sputtering apparatus is shown. In the following description, "apparatus for manufacturing an optical multilayer film interference filter" will also be referred to as "optical multilayer film manufacturing sputtering apparatus" (or simply "sputtering apparatus"). The optical multilayer film manufacturing sputtering apparatus 10 has a cluster arrangement and includes a plurality of vacuum chambers. Some of the vacuum chambers among the plurality of vacuum chambers are film-f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com