Drive with an energy recovery function having a brake pressure control valve

A technology of energy recovery and drive, applied in the direction of brakes, brake types, hydrostatic brakes, etc., can solve the problems of no longer storing pressure energy, structural complexity, unknown throttling function throttle unit, etc., to increase flow resistance , the effect of a low level of circuit complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

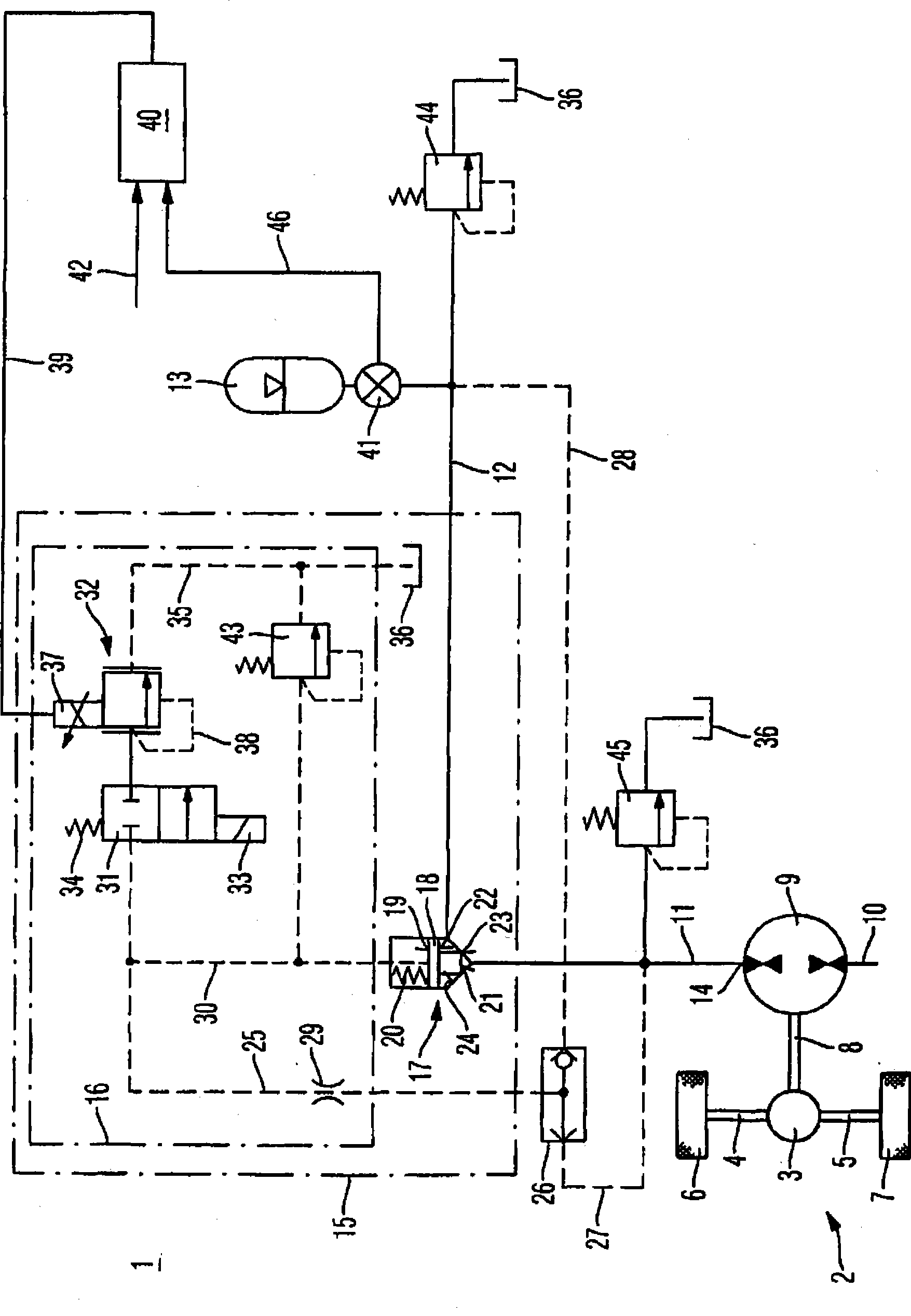

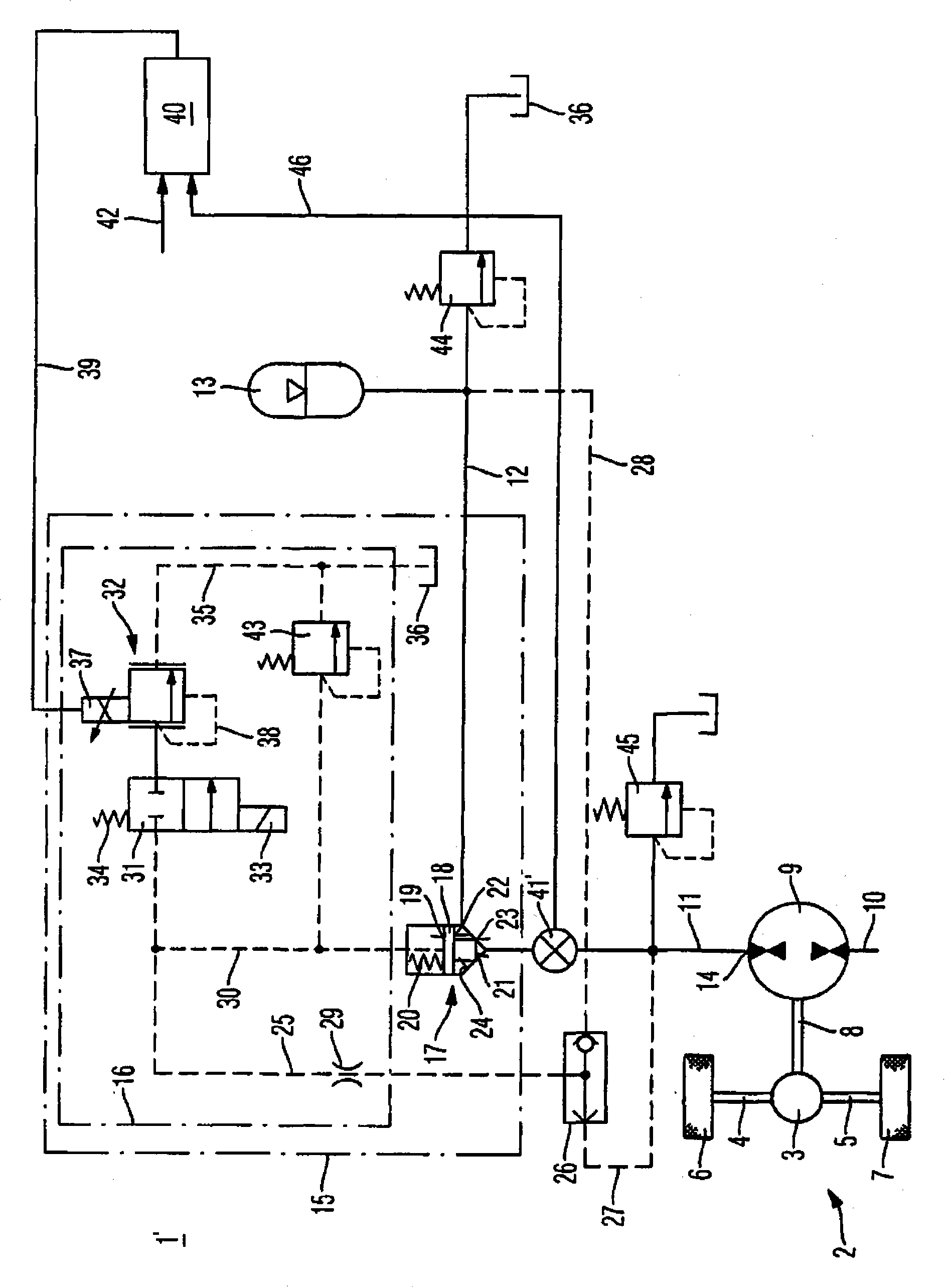

[0017] figure 1 is the hydraulic circuit diagram of the first embodiment of the driver 1 with energy recovery function. In the exemplary embodiment shown, the drive 1 is provided for energy recovery, for example in a travel drive 2 of a refuse collection vehicle or a fork-lift truck. These vehicles have intensive travel cycles, that is to say braking and acceleration operations often follow each other closely.

[0018] The travel drive 2 comprises a differential 3 which acts via a first half shaft 4 and a second half shaft 5 on a first driven wheel 6 and a second driven wheel 7 . The differential 3 is connected to a hydrostatic piston engine 9 via an output shaft 8 . For reasons of clarity, further components belonging to the travel drive 2 are not shown in the figure. The hydrostatic piston engine 9 can be a separate piston engine fully used for energy recovery or a hydraulic motor of the hydrostatic travel drive. The connection to the differential 3 of the travel drive 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com