Hydraulic elevation type tank transportation loading and unloading frame

A technology of hydraulic lifting and loading and unloading racks, applied in the directions of transportation and packaging, loading/unloading, packaging, etc., can solve the problems affecting the efficiency of vehicle use, reducing the use rate of vehicles, occupying funds and resources, etc., to achieve excellent mechanical properties, safe use High performance and cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

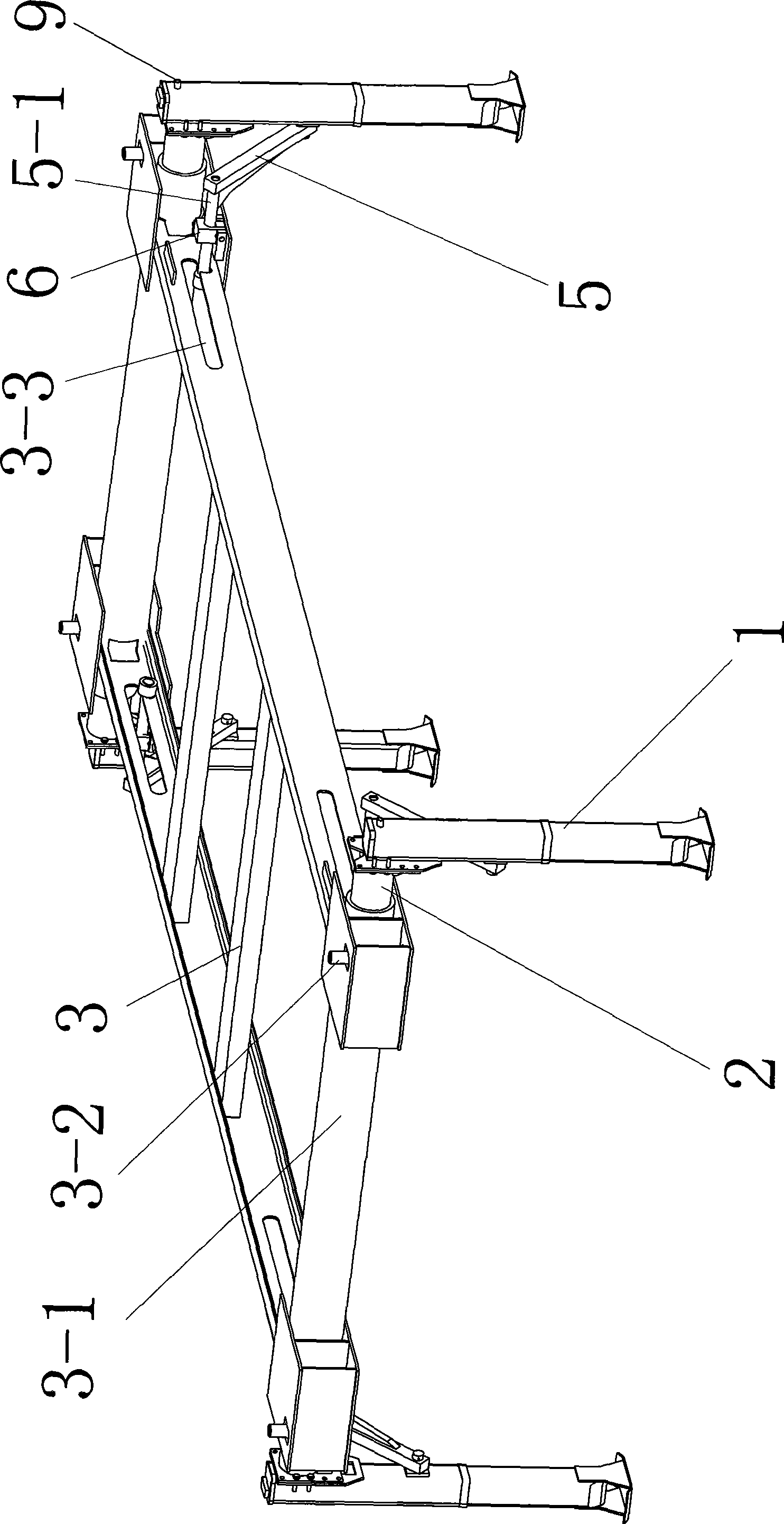

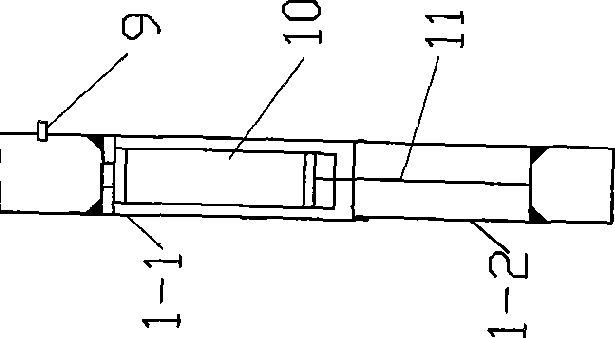

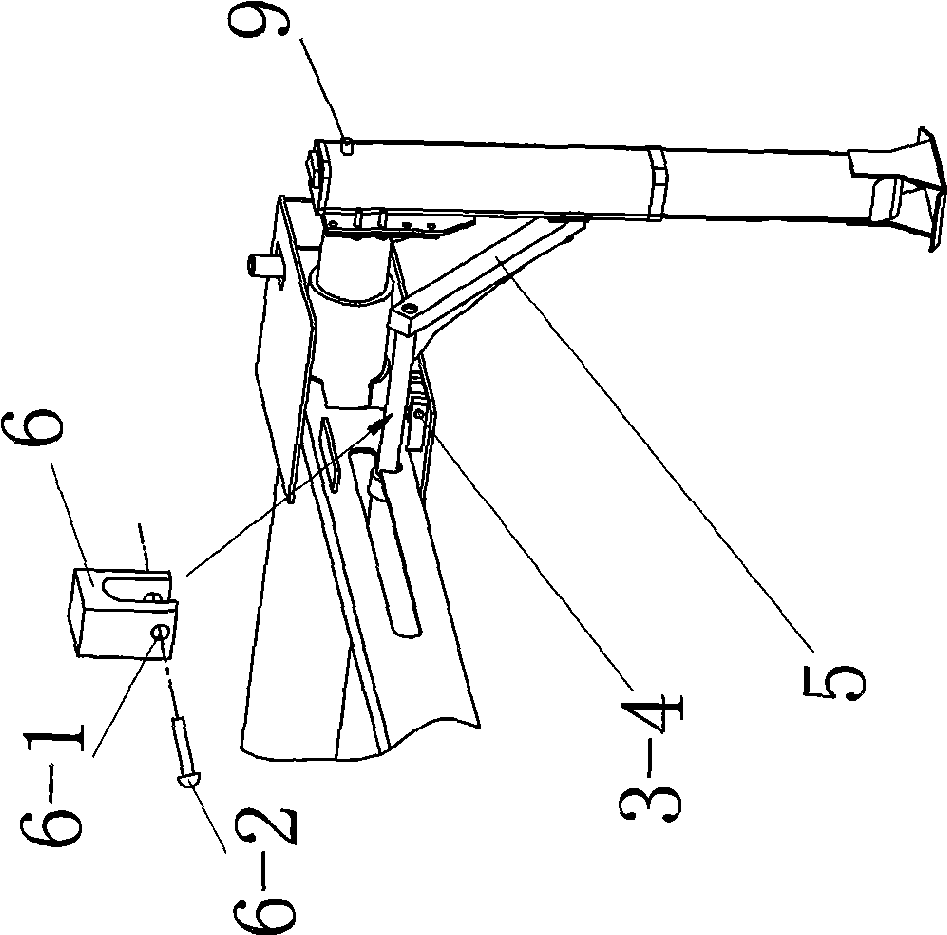

[0018] Such as figure 1 As shown, in the hydraulic lift type tank transportation and loading and unloading rack, there is a load-bearing frame 3 arranged horizontally for bearing the weight of the tank. The four corners of the load-bearing frame are equipped with a vertically arranged support leg 1, and each support leg It is hinged and reinforced with the load-bearing frame by a tendon rod 5 (the reinforcement structure is: one end of the tendon rod 5 is hinged on the support leg, and the other end of the tendon rod 5 is fixed to the horizontal sliding rod 5-1 embedded in the chute on the beam of the load-bearing frame In the positioning opening 3-31 of 3-3, after straddling the horizontal slide bar 5-1 with the gland 6, the pin 6-2 is inserted into the pin hole 6-1 of the gland 6 and the pin hole at the corner end of the load-bearing frame 3-4, the tendon rod 5 is fixed); the load-bearing frame is also provided with a lifting mechanism so that the load-bearing frame can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com