Technology for preparing butyronitrile-polychloroethylene blended rubber by mechanical blending

A technology of polyvinyl chloride and blended rubber, which is applied in the field of preparing nitrile-polyvinyl chloride blended rubber by mechanical blending method, which can solve the problems of high production cost, high glue consumption and energy consumption of blending and coagulation devices, and many wet spots and other issues, to achieve the effects of reducing production costs, meeting quality standards, and technically feasible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0011] Product Name: Nitrile-PVC Blend Adhesive

[0012] Formula: formula unit is weight percentage

[0013] Rubber raw material: nitrile rubber 58.48%;

[0014] Plastic raw material: polyvinyl chloride resin 29.24%;

[0015] Comprehensive additives: barium stearate 0.88%, zinc stearate 0.88%, epoxy soybean oil 1.75%, dioctyl phthalate 8.77%;

[0016] preparation

[0017] Preparation conditions, equipment

[0018] Ambient air pressure: one atmosphere;

[0019] Ambient temperature: room temperature;

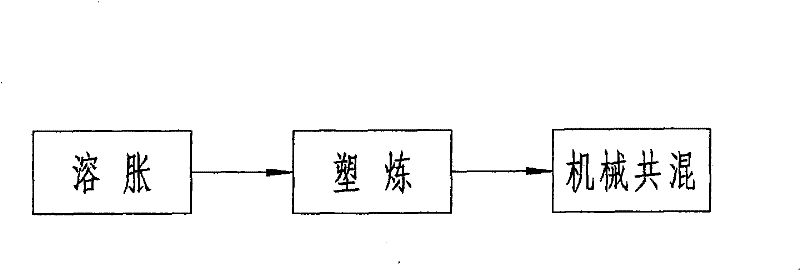

[0020] Preparation equipment: high-speed mixer, open rubber mixing machine, Mooney viscometer, roll temperature tester; process flow: see figure 1 , swelling, mastication, mechanical blending;

[0021] Process 1. Swelling:

[0022] Put the plastic raw materials and comprehensive additives in the formula into a high-speed mixer, mix at room temperature for 3 minutes, take it out, let it stand and mature for 12 to 240 hours, and obtain a swollen plastic;

[0023] Process tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com