Miniature piling machine

A pile driver and micro technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of safe construction distance limitation, inability to enter the site construction, etc., and achieve the effect of preventing foundation settlement, good adaptability and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

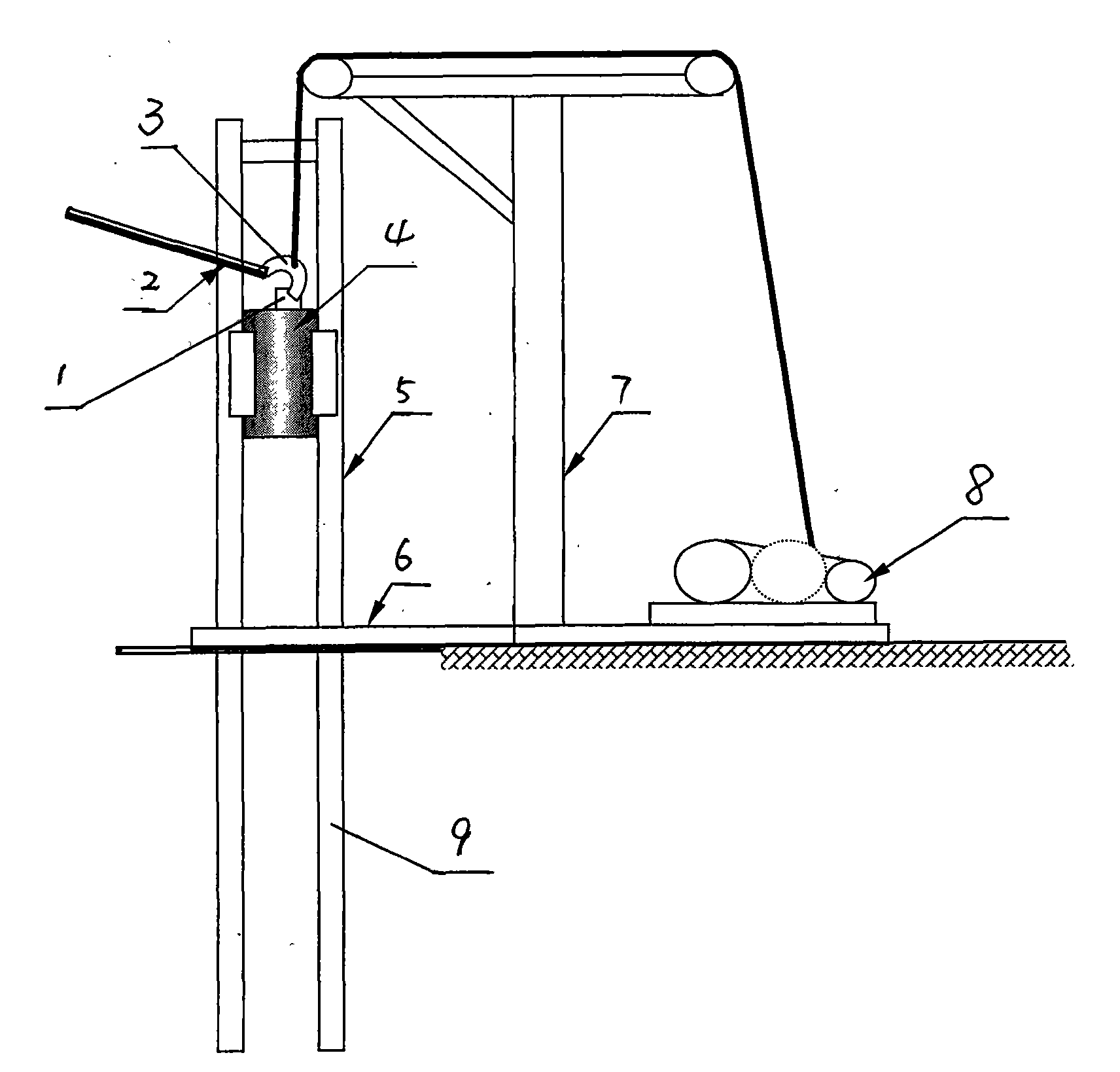

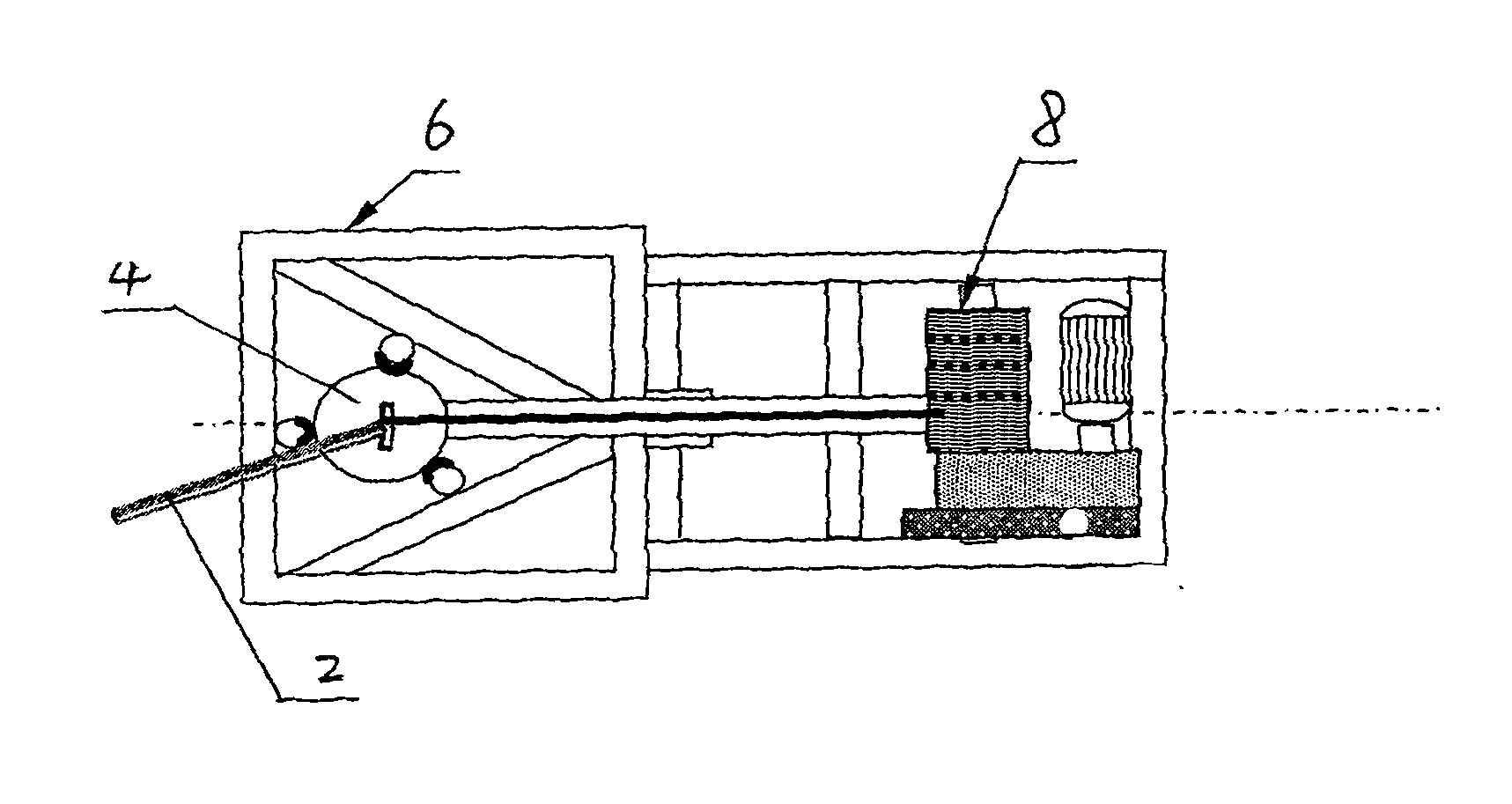

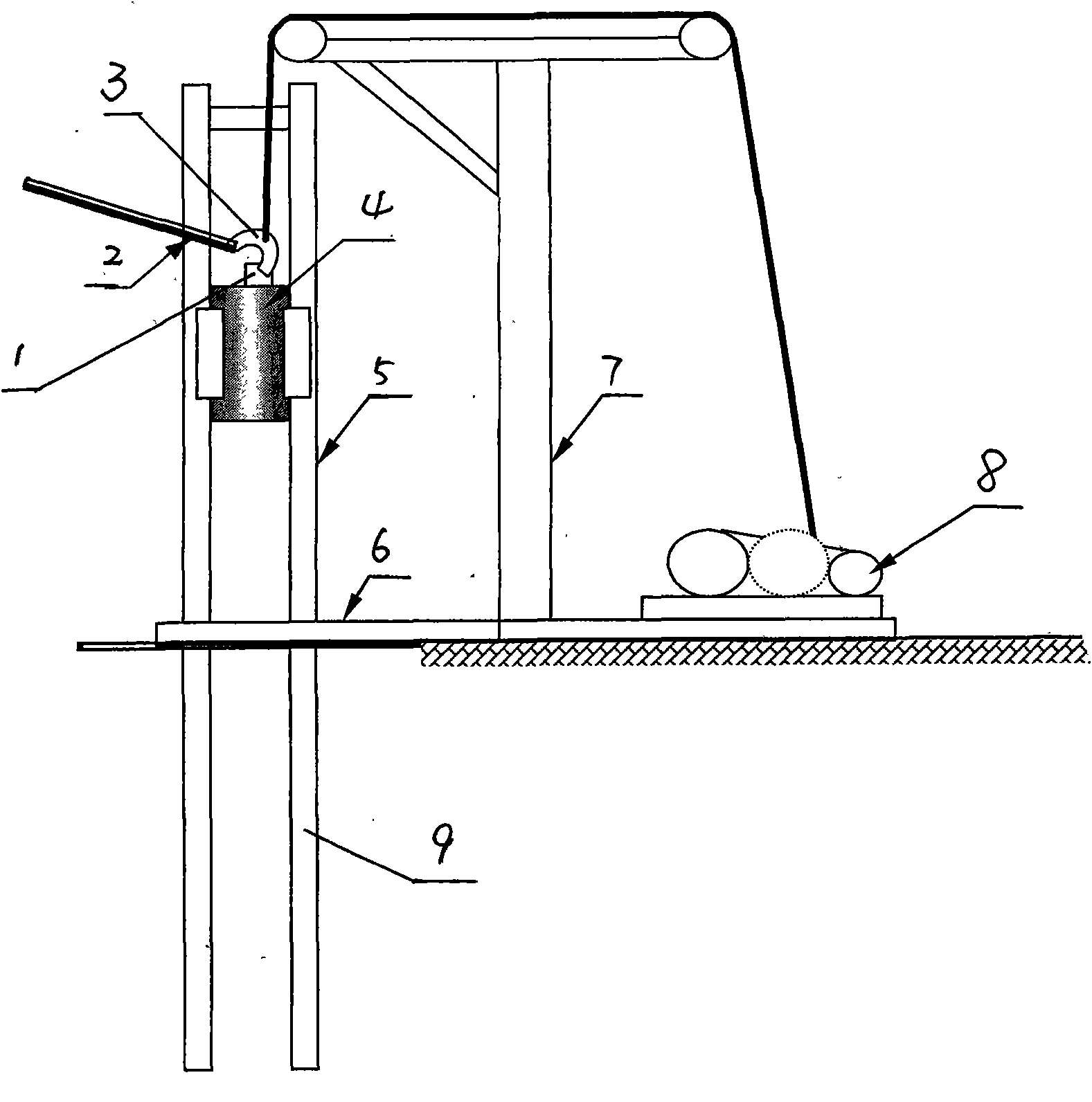

[0016] A small piling equipment, including a base 6, a frame 7, a hoist 8 and a pile hammer 4, the wire rope of the hoist is connected to the pile hammer 4 through a guide pulley on the upper part of the frame, the height of the frame 7 is 1.50-2.20m, and the frame 7 The front part is provided with a pile hammer guide mechanism, and the pile hammer guide mechanism includes an above-ground guide rod 5 arranged on the upper part of the base and an underground guide rod 9 arranged on the lower part of the base, and a hanging ring 1 is arranged on the top of the pile hammer 4, What cooperates with link 1 is provided with link hook 3, and link hook 3 is provided with a long control handle 2, and the end of winch wire rope is hinged with the middle part of described link 3 hook body. The above-ground guide rod 5 and the underground guide rod 9 are set as one, three are arranged in parallel, the pile hammer is arranged between the three guide rods, and the pile hammer 4 is correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com