Deep-thin layer natural alkali, salt and saltpeter well-to-well multi-layer connection exploitation process

A trona, thin-layer technology, applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc., to achieve good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

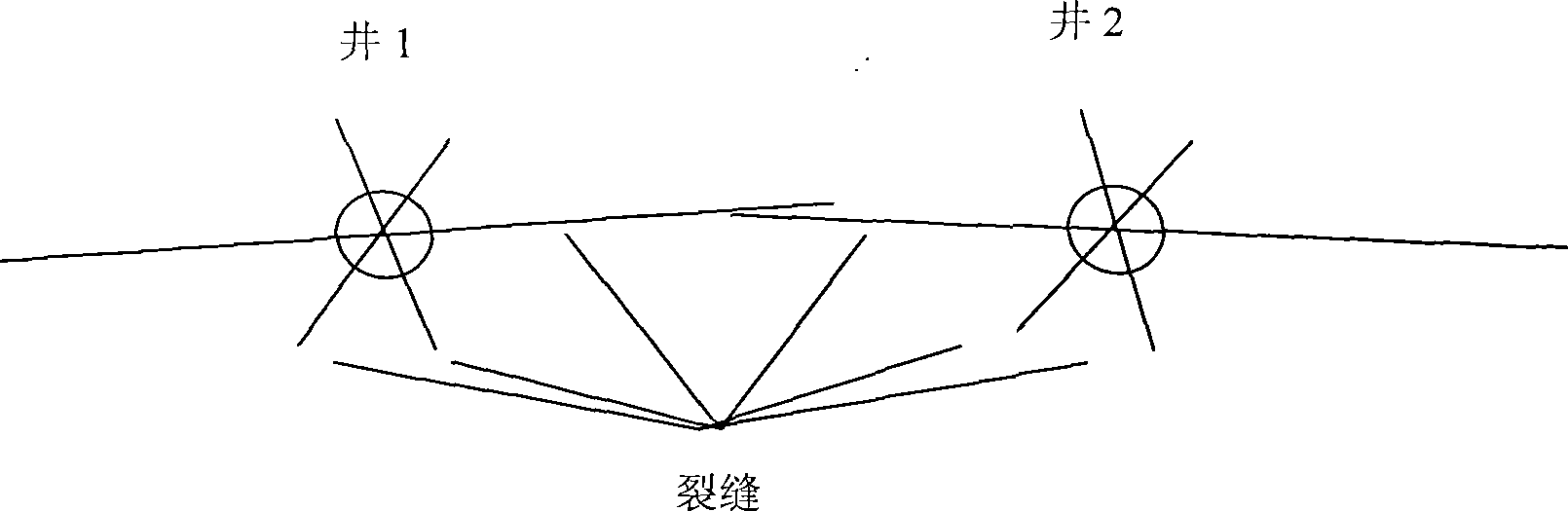

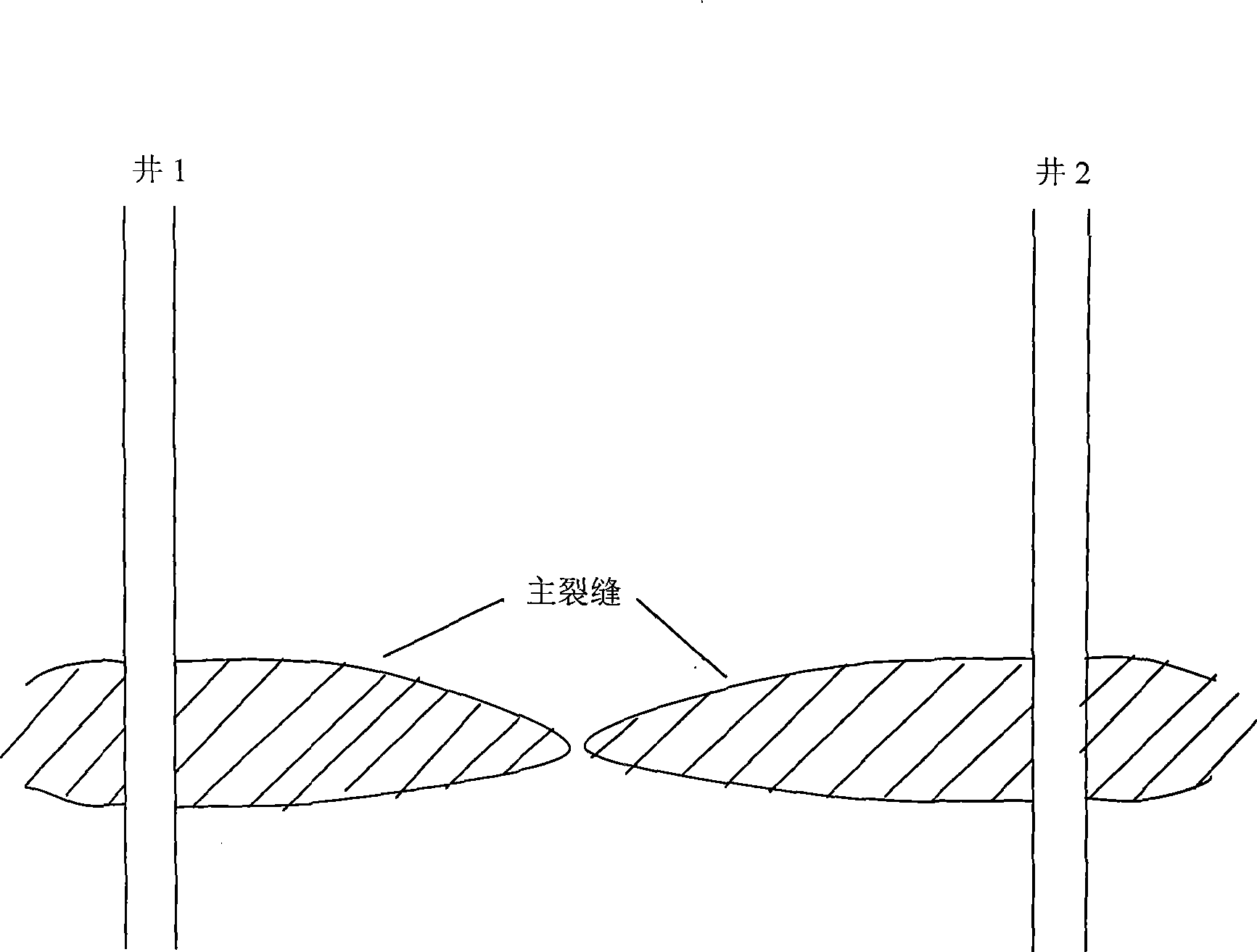

[0026] Example: For a pair of wells with a depth of about 2500 meters and a well spacing of 425 meters, the water injection wells are drilled first. After the stratum direction is basically determined and the principal stress direction is determined, single fracturing and fracture direction determination are started, and then normal production construction begins. groove. According to the formation trend and principal stress direction, the location of the brine extraction well is determined. After the completion of brine extraction wells, production and construction of tanks began.

[0027] The operating index for production tank construction is; water injection for 6 hours (the water injection volume is ∽40m 3 / h, pressure ∽30MPa), boring well for 4 hours (water injection ∽0m 3 / h, pressure ∽20MPa or so), circulating water return for 2 hours (return water volume is 40-100m 3 / h, pressure 12-20MPa), such reciprocating cycle of fracturing and pressure relief, the two wells w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com