Integral top beam

A roof beam and integral technology, which is applied to roof beams supporting mine roofs, mining equipment, earth-moving drilling, etc., can solve the problems of strict geological conditions, high price, and inconvenient underground transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

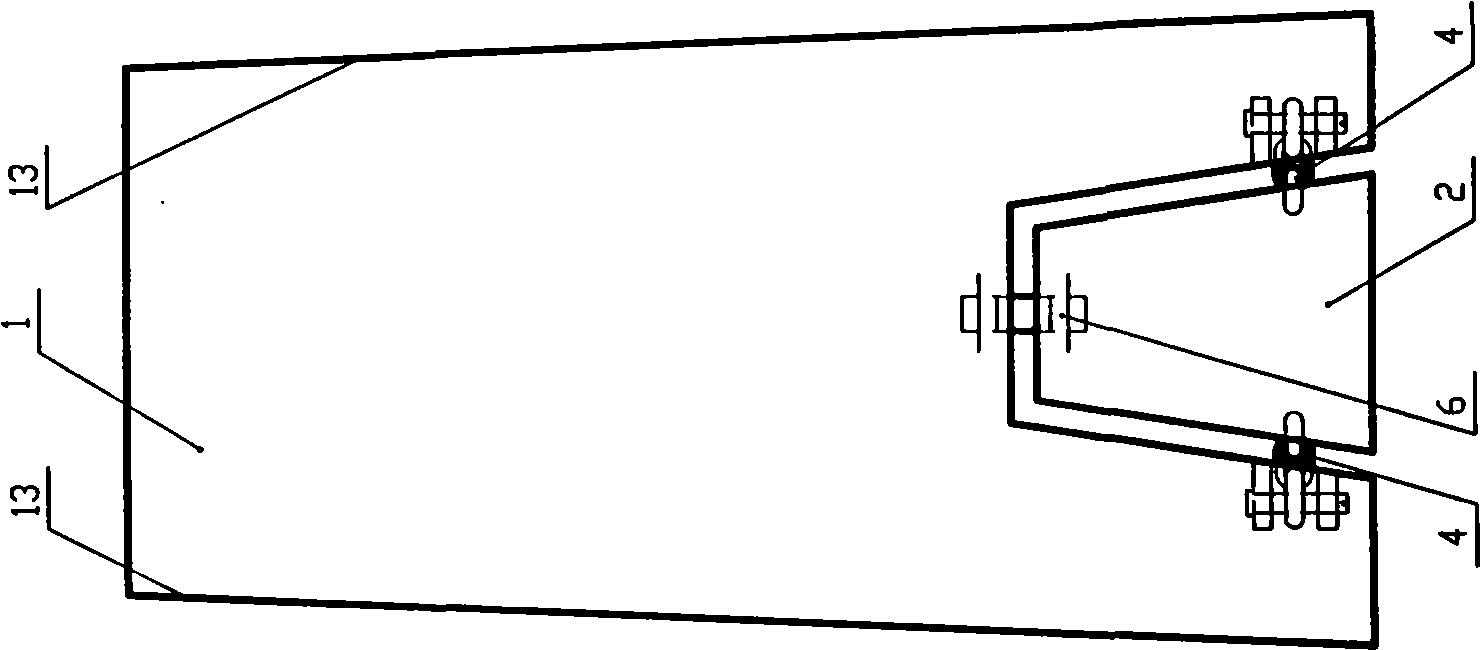

[0023] combine figure 2 , the second embodiment of an integral top beam of the present invention includes a main top beam 1 , a filling part 2 , a link hinge structure 6 connecting the main top beam 1 and the filling part 2 and a flexible piece 4 . In this embodiment, the two sides of the rectangle are changed from vertical straight lines to oblique lines 13, and at this time, the top beam is a trapezoidal approximate rectangle.

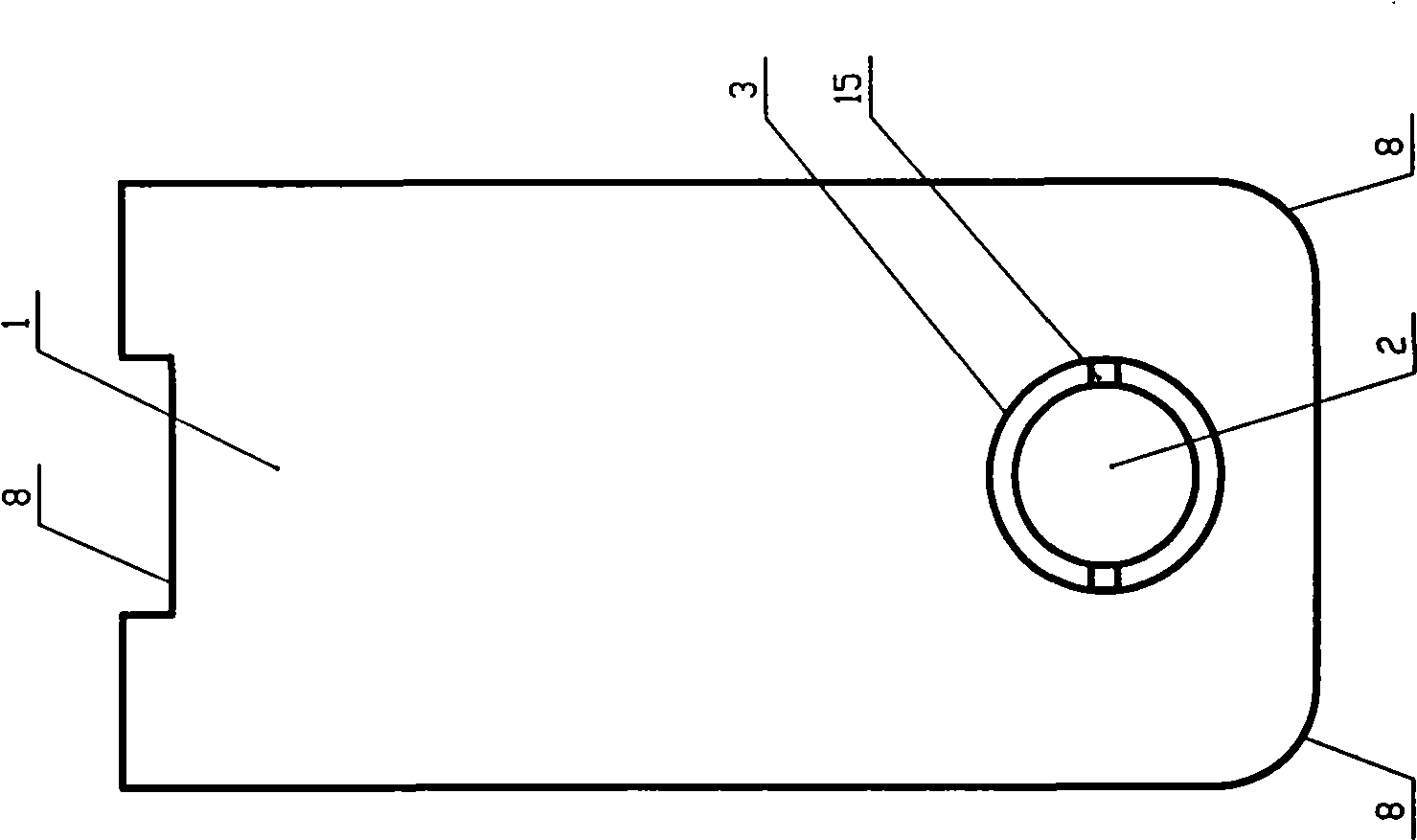

[0024] combine image 3 , the third embodiment of an integral top beam of the present invention, including a main top beam 1, a filling part 2, a guide rail 3, a limiting device 15 and a small structure 8 in the shape of an arc chamfer and a small groove.

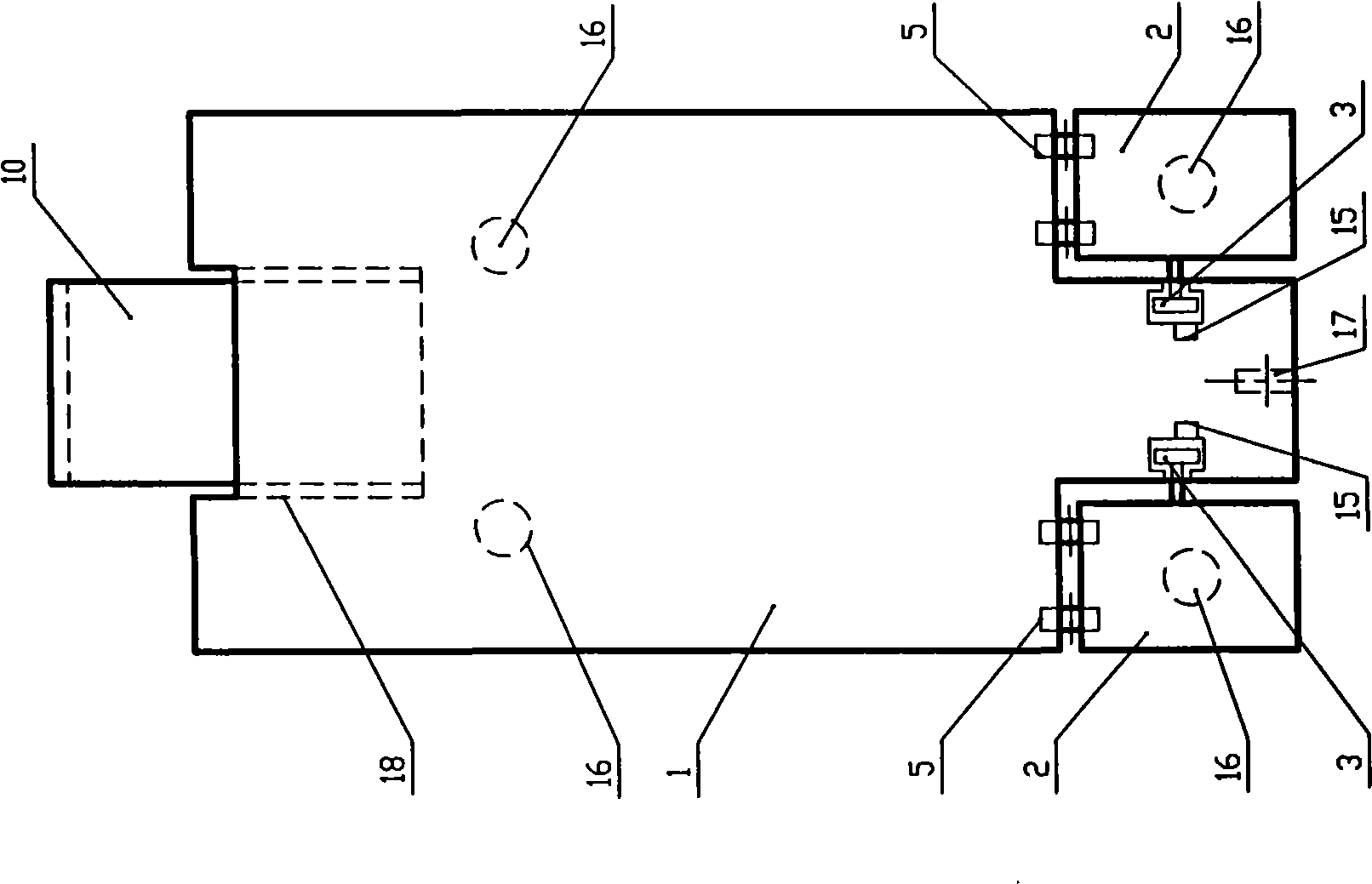

[0025] combine Figure 4 , the front view and top view of the fourth embodiment of an integral top beam of the present invention, including a main top beam 1 whose top surface is a plane 10, a cover beam 9 with a top surface 11 inclined downward, a filling part 2, and a connecting filling part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com