Automatic sampling apparatus for rare earth magnetic powder

A technology of automatic sampling device and rare earth magnetic powder, which is applied in the direction of sampling device, etc., to achieve the effects of high work efficiency, novel structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

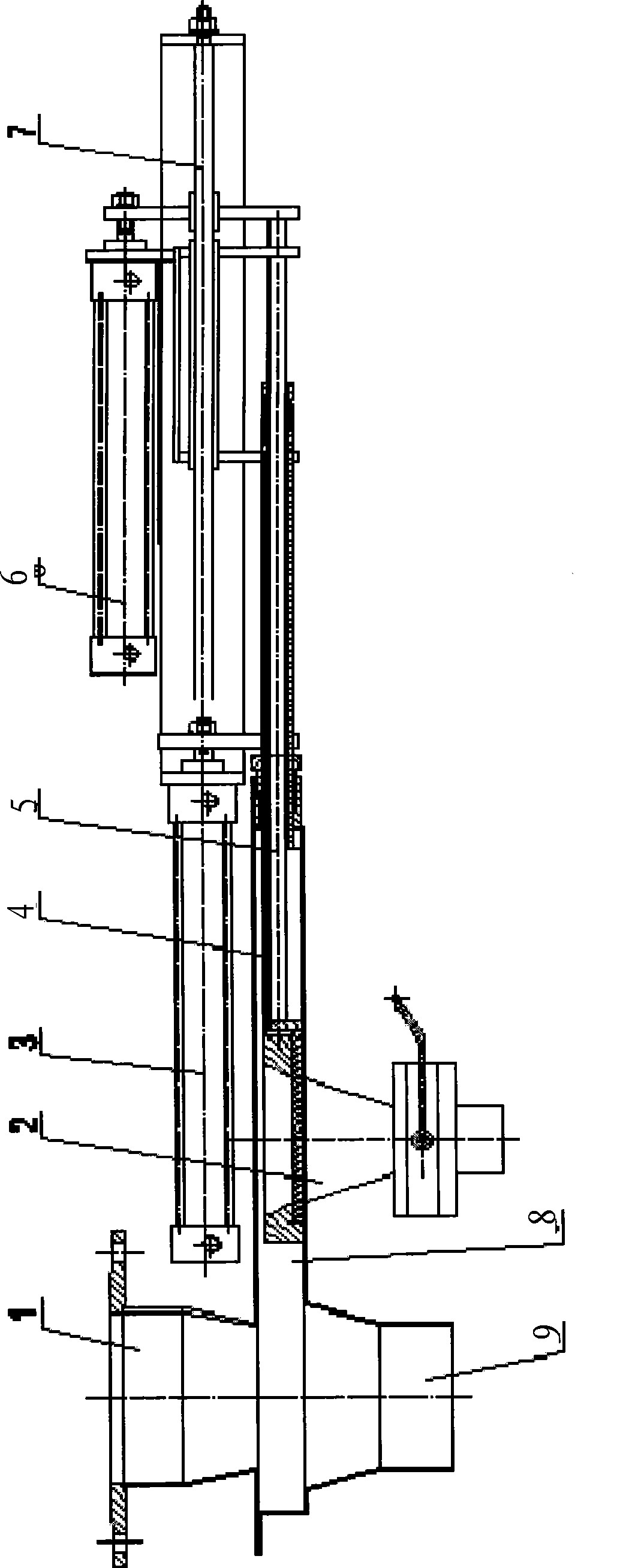

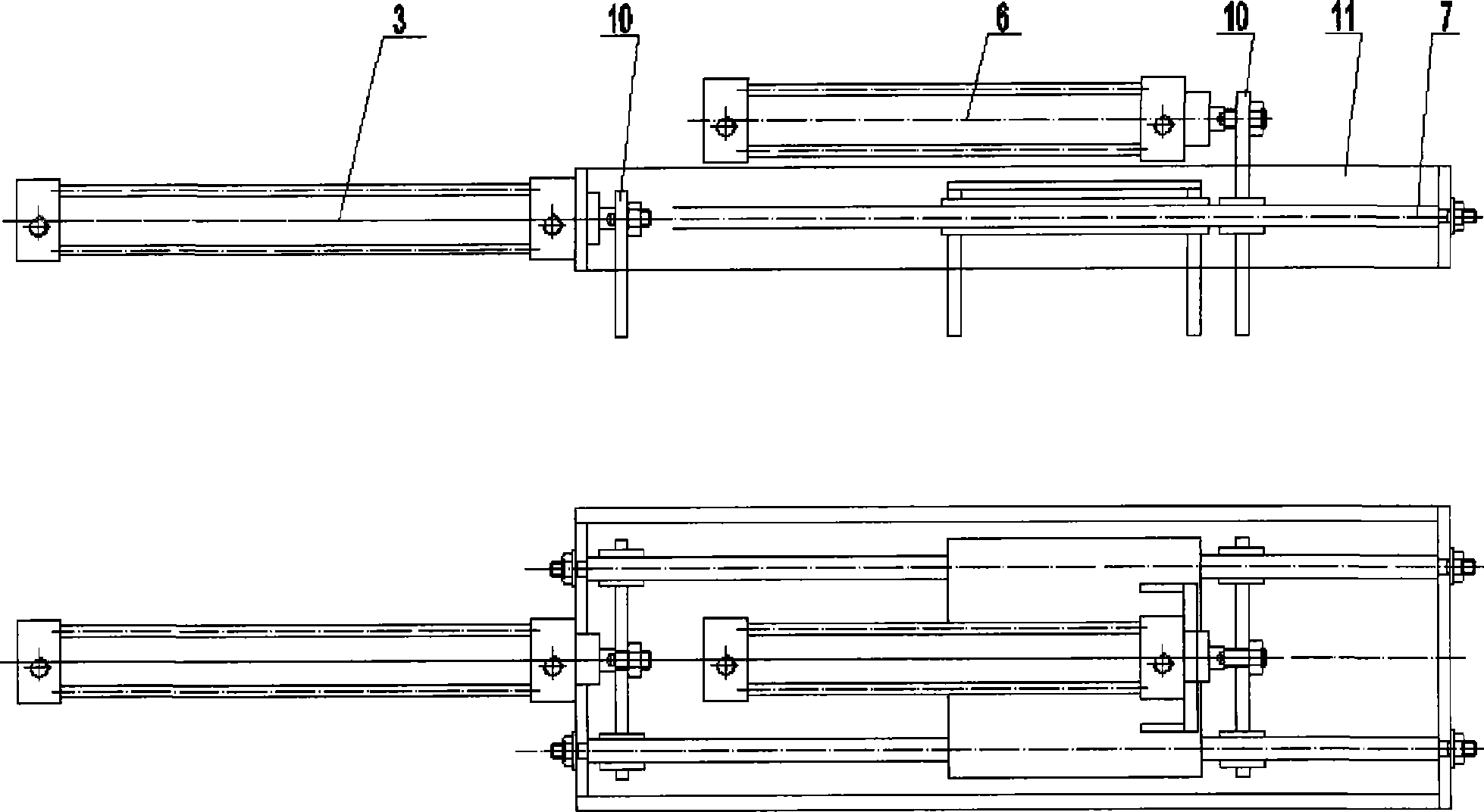

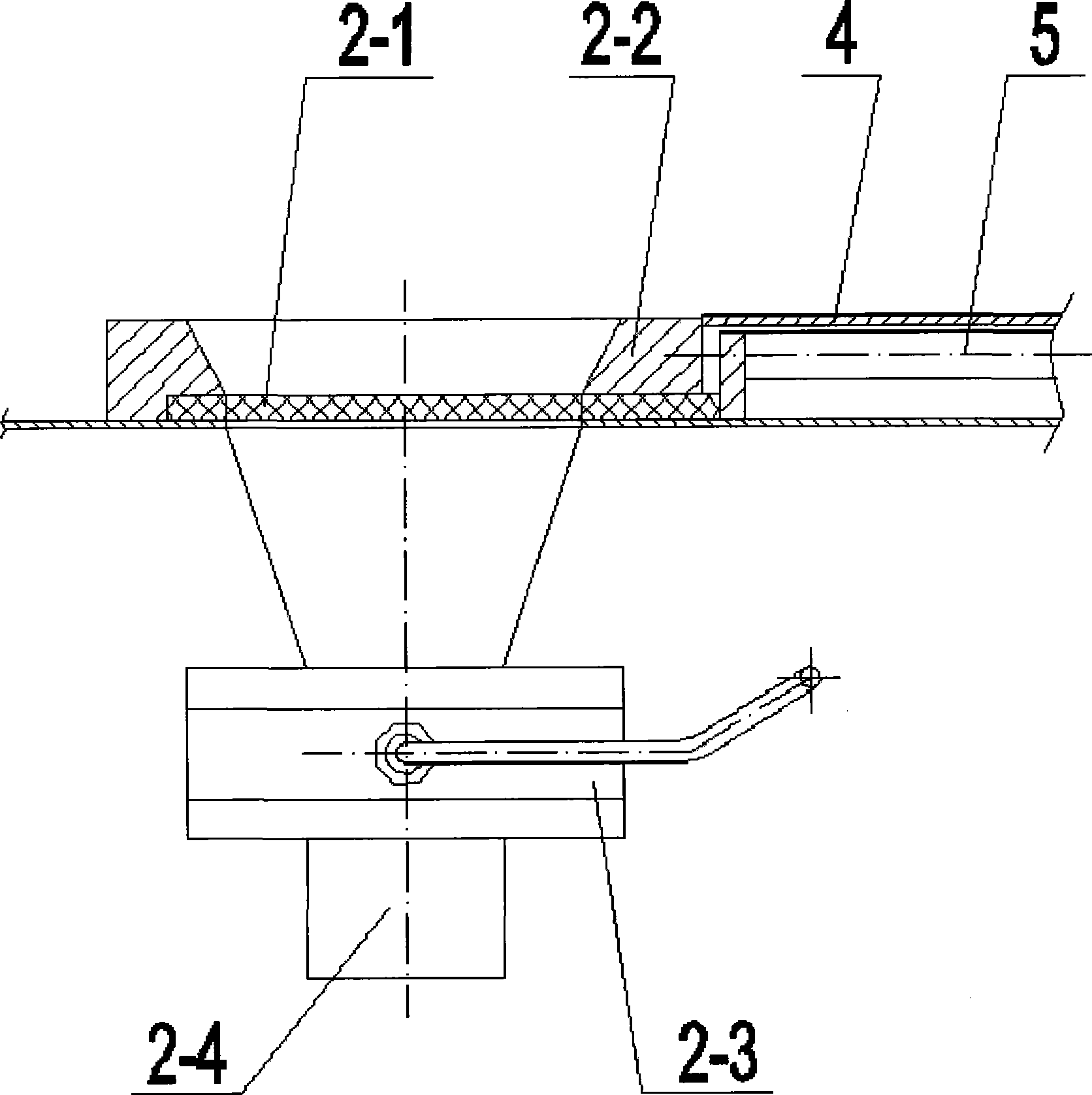

[0018] The present invention is by upper hopper (1), sampling mechanism (2), sealing plate (2-1), sampling disk (2-2), pneumatic butterfly valve (2-3), sampling funnel (2-4), cylinder 1 ( 3), piston inner cylinder (4), piston rod (5), cylinder II (6), polished rod (7), material box (8), lower hopper (9), connecting plate (10), grooved base ( 11) and so on.

[0019] The material box (8) made of metal is a hollow sealed cuboid, sealed with an O-ring to reach a vacuum state, filled with argon gas for protection, and the upper part of one end of the material box (8) is equipped with an airflow grinding phase for rare earth magnetic powder processing. The connected upper hopper (1) is equipped with a lower hopper (9) correspondingly below; a sealing plate (2-1) and a sampling tray (2-2) are installed in the middle of the material box (8), and the sampling tray (2 -2) Place it on the top surface of the sealing plate (2-1), rely on the self-structure of the sampling plate (2-2) and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com