Computing method for roll profile of steckel mill

A technology of roll profile and steckel mill, which is applied in the field of calculation of the roll profile of a steckel mill, can solve problems such as high inter-roll pressure and roll spalling, and achieve the suppression of roll spalling, meet the requirements of plate crown, and the contact pressure between rolls well-distributed effect

Inactive Publication Date: 2010-09-08

NANJING IRON & STEEL CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

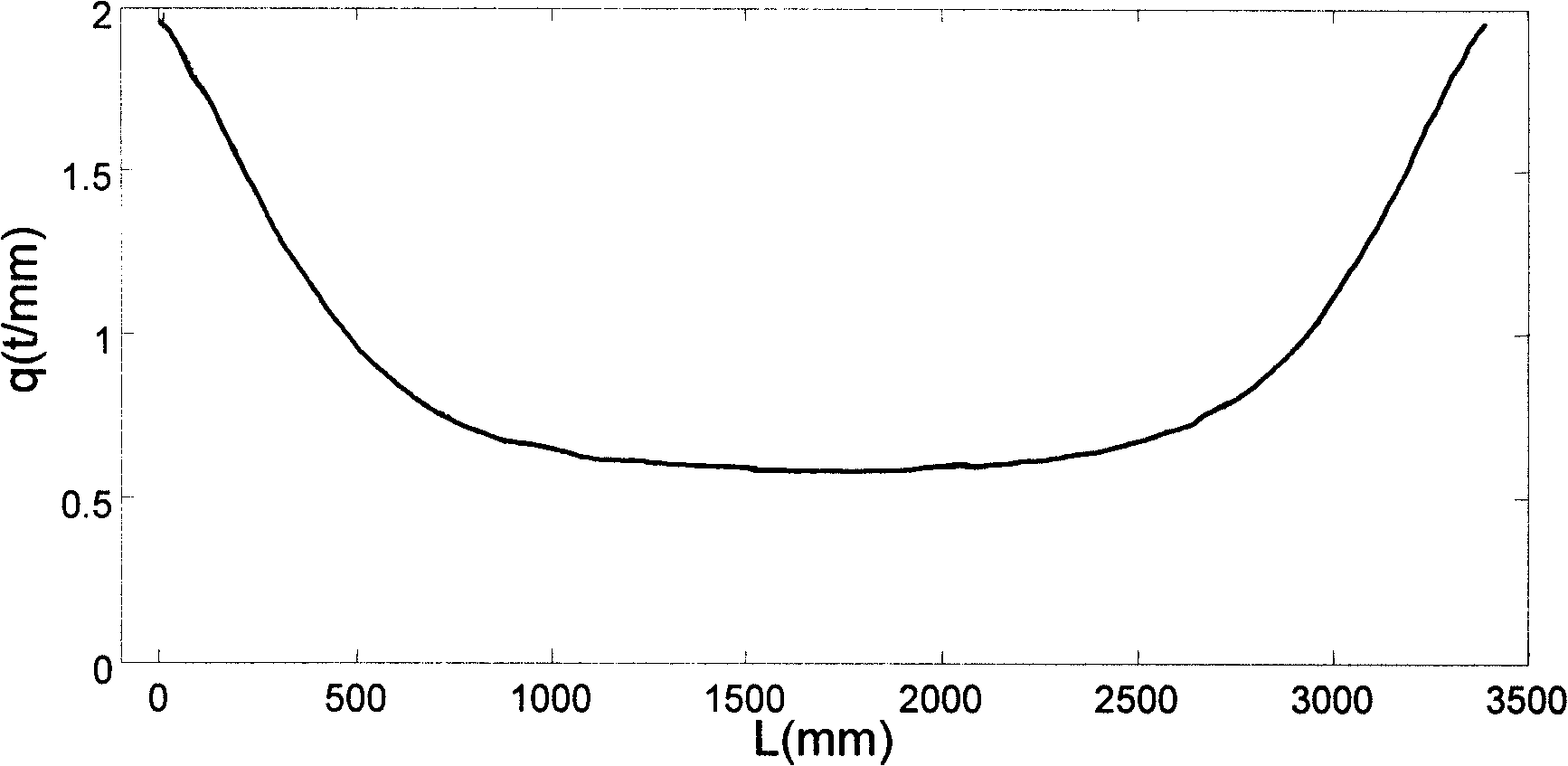

In order to improve the force between the rolls, a certain amount of chamfering can be applied to the support rolls, but during the rolling process, the pressure between the rolls at the chamfers is too large, especially in the middle and late stages of the work cycle of the rolls. The pressure between the rolls rises even more. Figure 3 is the distribution of the pressure between the rolls along the roll body direction (L) when the backup rolls are chamfered rolls and the work rolls are flat rolls. There is still a risk of peeling off the rolls here.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a method for calculating the roll shape in the field of metallurgy, in particular to a method for calculating the roll shape of a steckel mill. The invention adopts the calculation method which influences a function method or a finite element method, and considers designing the original roll shape of rolls on the basis of abrasion and thermal expansion of the rolls under the condition of certain rolling procedures. The method calculates the rolling force and the deflection and wafering of working rolls and supporting rolls according to the rolling procedures, and thencalculates the rolling force, the contact pressure between the rolls and the thickness distribution conditions of rolling pieces so as to obtain reasonable roll shape of which the pressure between the rolls is reasonably distributed and the plate convexity meets the requirements, of the supporting rolls and the working rolls, and the roll bending force. By adoption of the method to design the supporting rolls and the working rolls, the pressure distribution state between the rolls of the supporting rolls and the working rolls can be obviously improved, spallation of the rolls is inhibited, and simultaneously the plate convexity requirement can be met.

Description

technical field The invention relates to a calculation method of a roll profile in the field of metallurgy, in particular to a calculation method for a roll profile of a steckel mill. Background technique When the rolling method is used to produce metal sheets and strips, reducing the radius of the rolls can reduce the rolling force, but at the same time it also reduces the bending resistance of the rolls, making the cross-section of the rolled piece more convex, that is, the convexity of the plate becomes larger , leading to product failure in severe cases. In order to reduce the rolling force while suppressing roll bending, the steckel mill adopts a four-high rolling mill, that is, a pair of work rolls with a smaller diameter and a pair of backup rolls with a larger diameter, and the back-up rolls are pressed against the work rolls. On the surface, the back-up rolls are mounted on the mill stand through the back-up roll chocks. During rolling, the deformation of the roll...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G05B19/18

Inventor 党军王道远周成张建国郭怀兵滕达杨兆根李强

Owner NANJING IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com