Computing method for roll profile of steckel mill

A roll shape and furnace coil mill technology, applied in the field of calculation of the roll shape of a furnace coil mill, can solve problems such as roll peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] In this embodiment, a certain furnace rolling mill is taken as an example. The size of the backup roll is Φ1950mm×3400mm (roll diameter×roll body length), the size of the working roll is Φ1010mm×3500mm (roll diameter×roll body length), and the typical product is X70 pipeline steel , the specification is 10mm×3000mm, the blank size used is 150mm×3000mm (thickness×width), and the rolling procedure is 150mm→131mm→112mm→100mm→88mm→77mm→68mm→58mm→50mm→42mm→35mm→30mm→25mm →21mm→18mm→16mm→14mm→12mm→11mm→10mm.

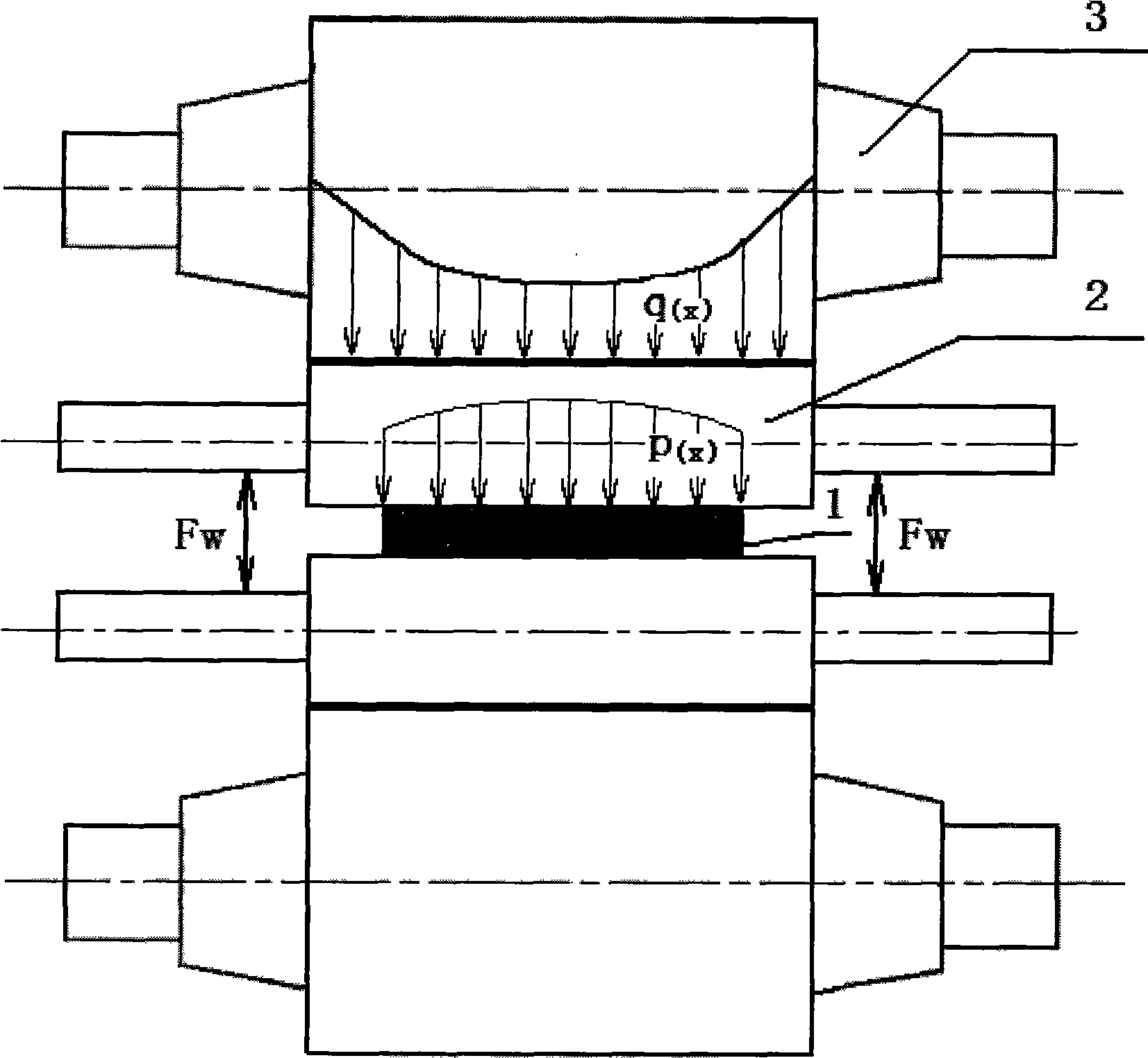

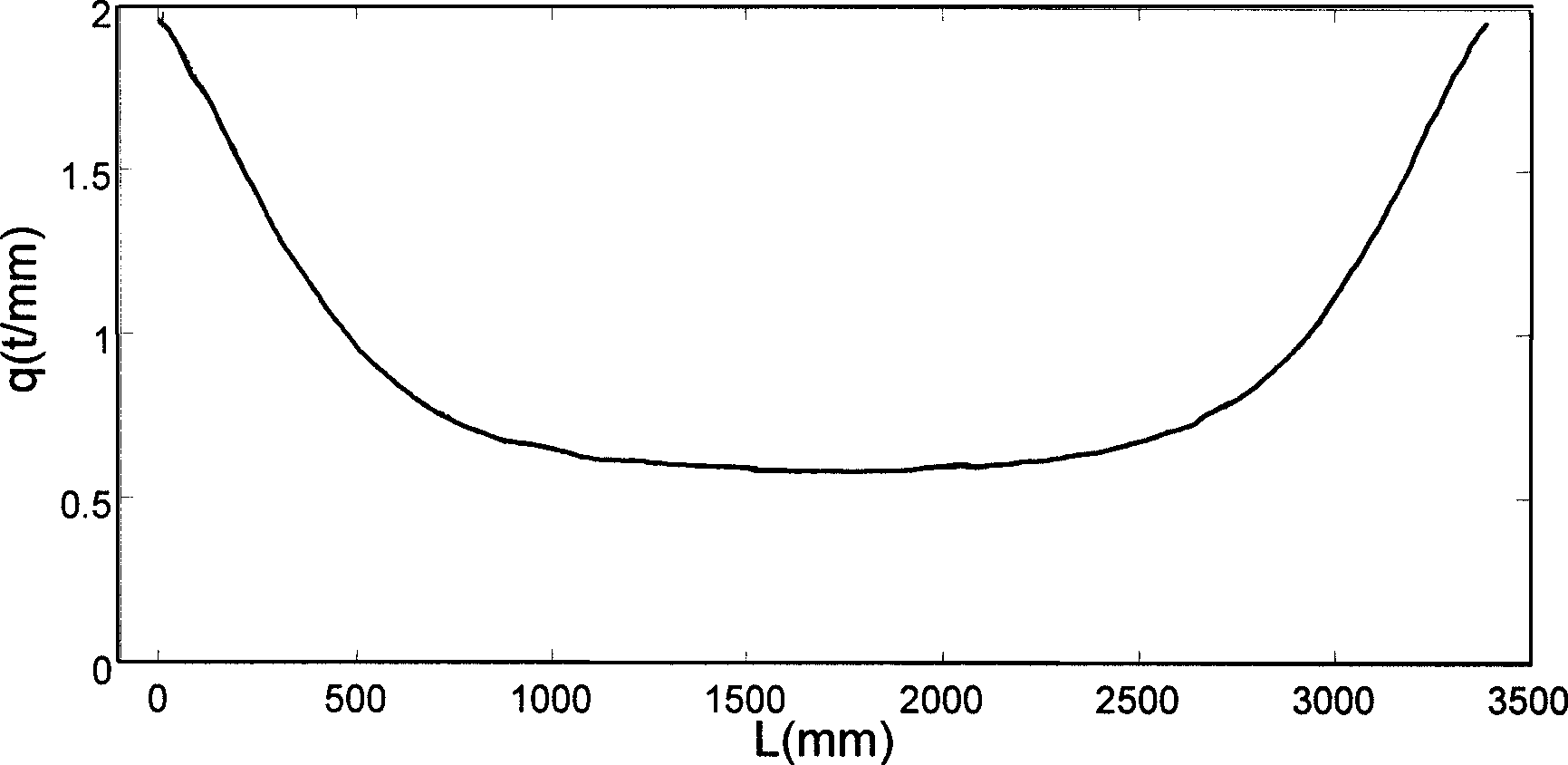

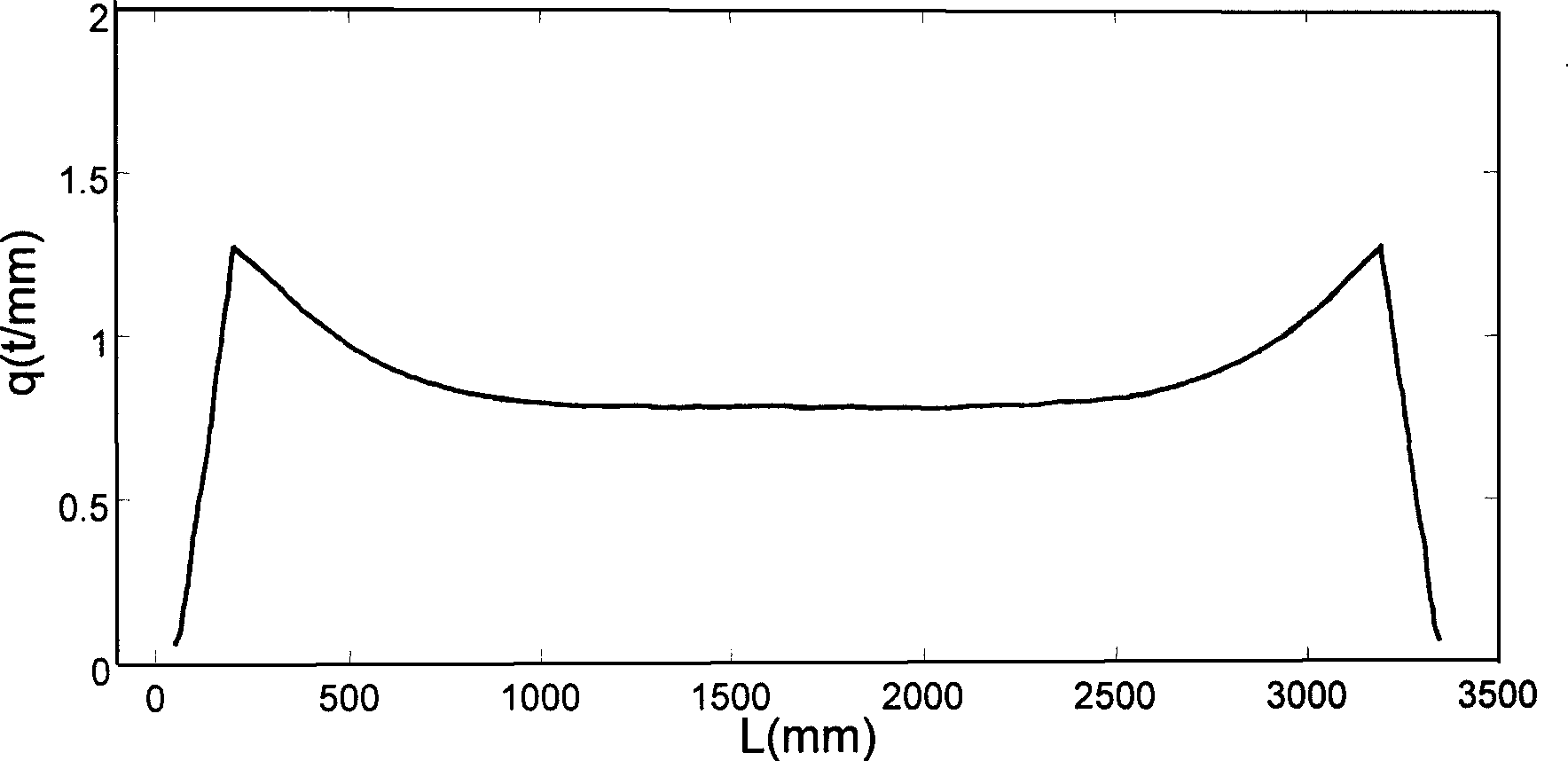

[0066] The calculation method of the roll shape of the steel-steel mill of the present invention is used for calculation, wherein the calculation of the pressure distribution between the rolls and the thickness distribution of the rolled piece is carried out by the influence function method, and the original support rolls and work rolls are all flat rolls, resulting in the edge of the support roll. Large area peeling off at the top, chamfering (2mm × 200mm, height × len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com