Charger for automatically recognizing battery

An automatic identification and charger technology, applied in the direction of mechanical tension relief devices, etc., can solve the problems of easily damaged batteries, easy overcharging, long charging time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

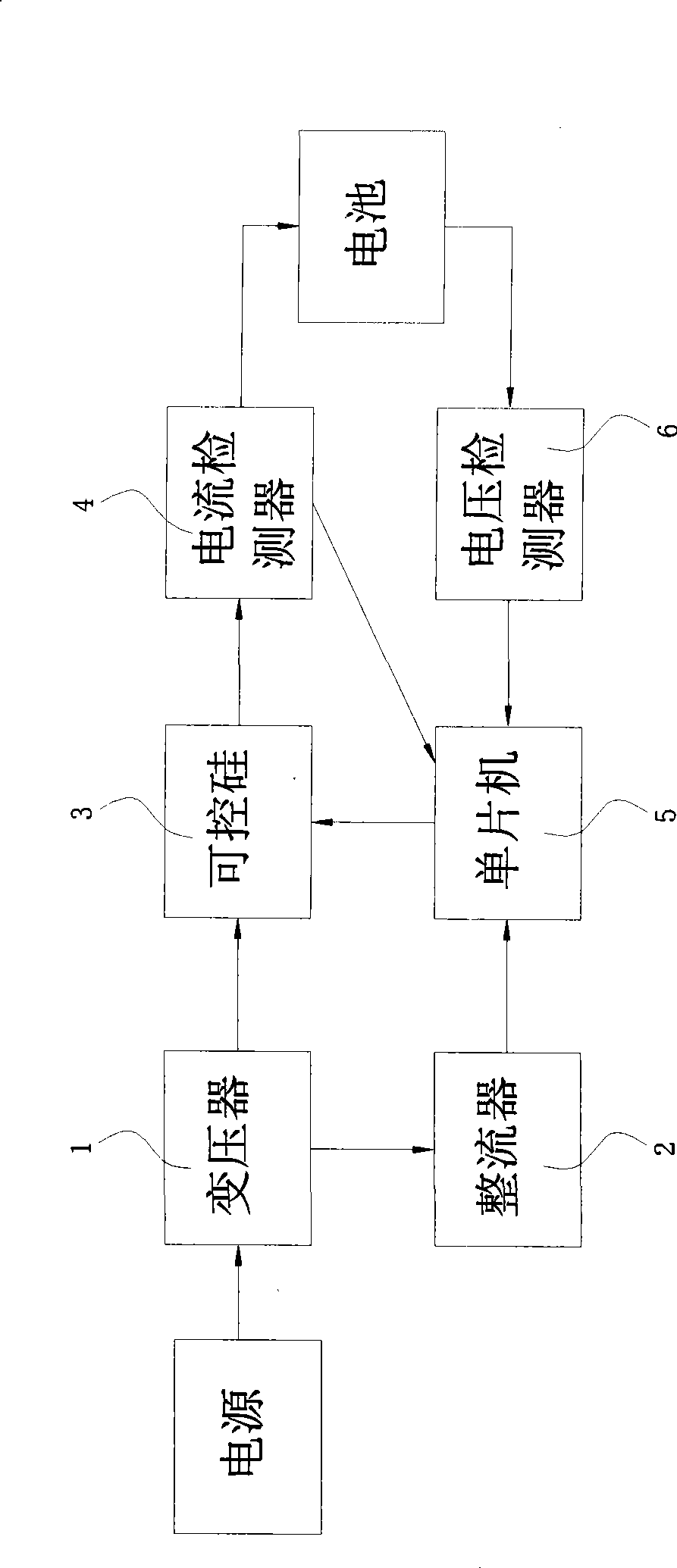

[0010] refer to figure 1 , The charger for automatically identifying batteries of the present invention includes a transformer 1 , a rectifier 2 , a thyristor 3 , a current detector 4 , a single-chip microcomputer 5 and a voltage detector 6 . Transformer 1 is a power frequency transformer, and its output end has main and auxiliary output windings, wherein the main output winding is connected with thyristor 3, and provided to the battery to be charged after being rectified by thyristor 3; the auxiliary output winding is connected with rectifier 2, and The rectifier provides the single-chip microcomputer 5 after rectification. The thyristor 3 is connected to the transformer 1 and the single-chip microcomputer respectively, and the thyristor 3 adjusts the conduction time of the thyristor according to the instruction of the single-chip microcomputer 5, converts the alternating current output by the transformer into direct current, and outputs a stable voltage and constant current...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com