Joint and/or bearing arrangement

A bearing device and joint technology, applied in the directions of shafts and bearings, bearing components, pivots, etc., can solve the problems of difficult installation of the joint device, and achieve the effect of tight and well sealed connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

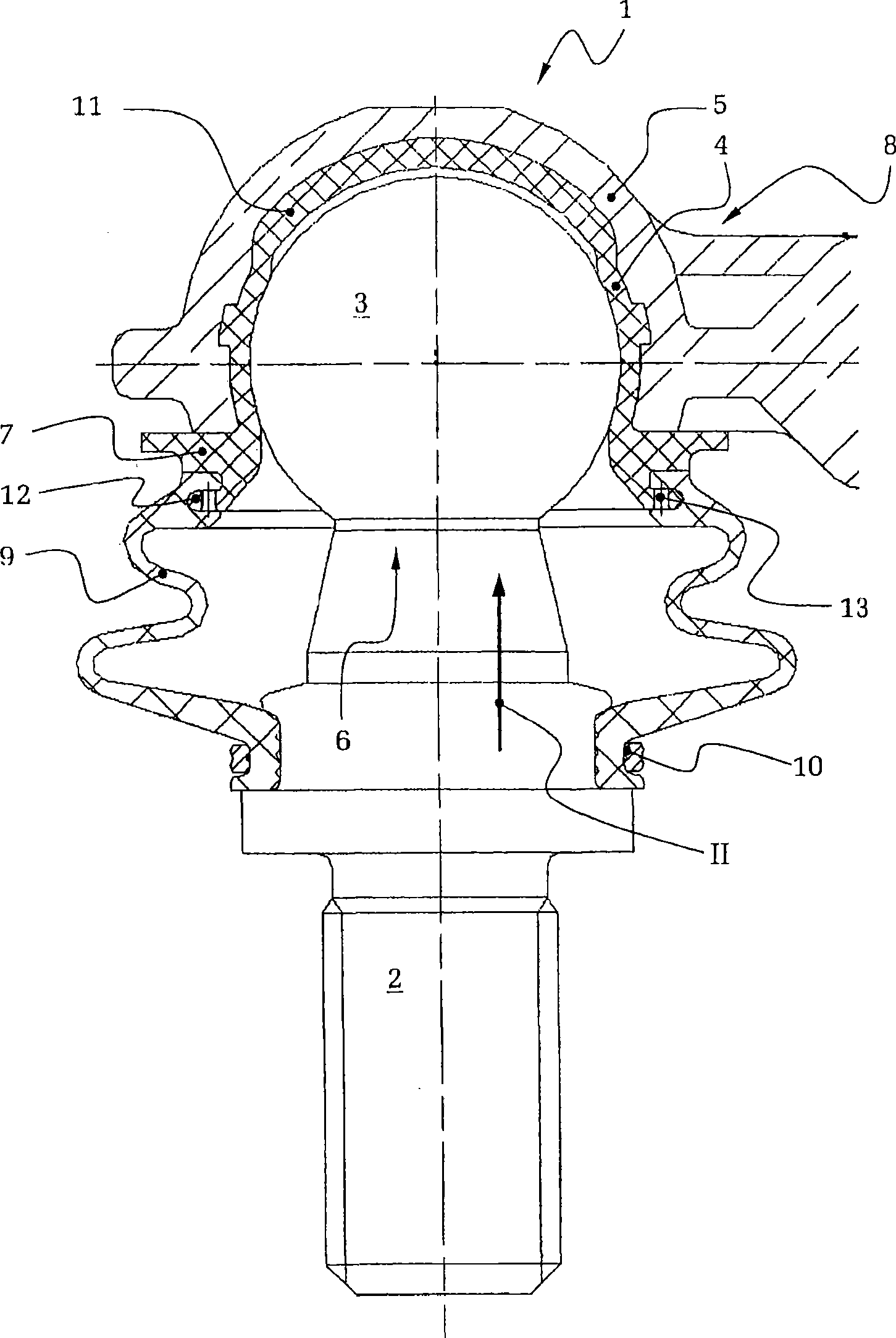

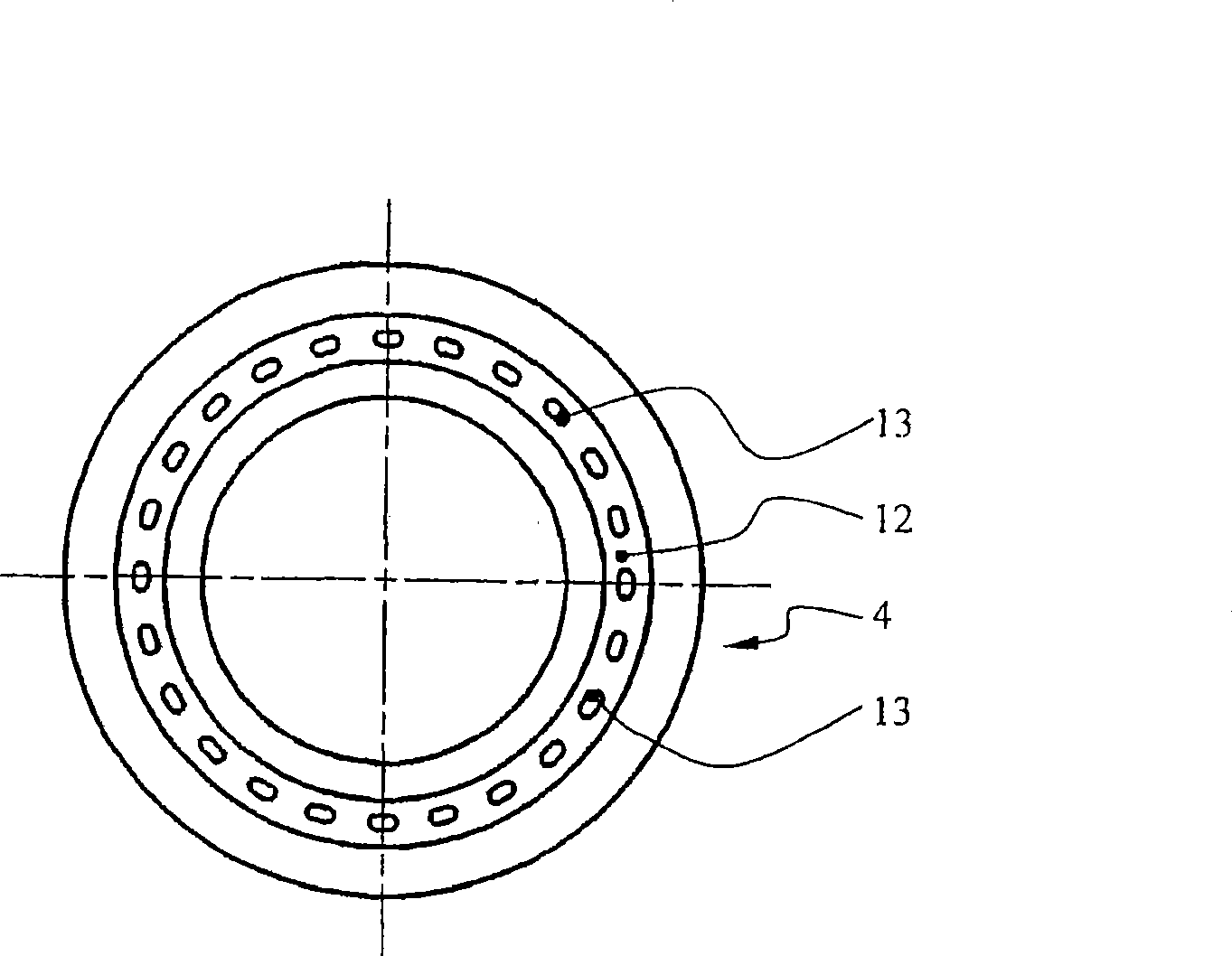

[0020] figure 1 The joint device 1 shown in FIG. 2 comprises an axially extending joint pin 2 with a widened top 3 formed, for example, by a substantially spherical profile. The top 3 can be held movably within or relative to a substantially continuously lubricated joint or bearing bush 4 , which is itself surrounded at least partially radially outwardly by a housing 5 .

[0021] For assembly, the joint tip 3 is first inserted into the joint bushing. The housing 5 is formed, for example, as an compression-molded part 8 or injection-molded part of the joint bush 4 with the joint tip 3 held therein. Liquid hot materials can be used for such compression molding or injection molding, which are formed from metal, for example as zinc die-casting parts, and are morphologically hard and dimensionally stable after subsequent cooling without further processing The housing 5 can then be formed integrally with, for example, an axle or a steering mechanism.

[0022] The joint and / or bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com