Integral bike metal seat tube and molding method thereof

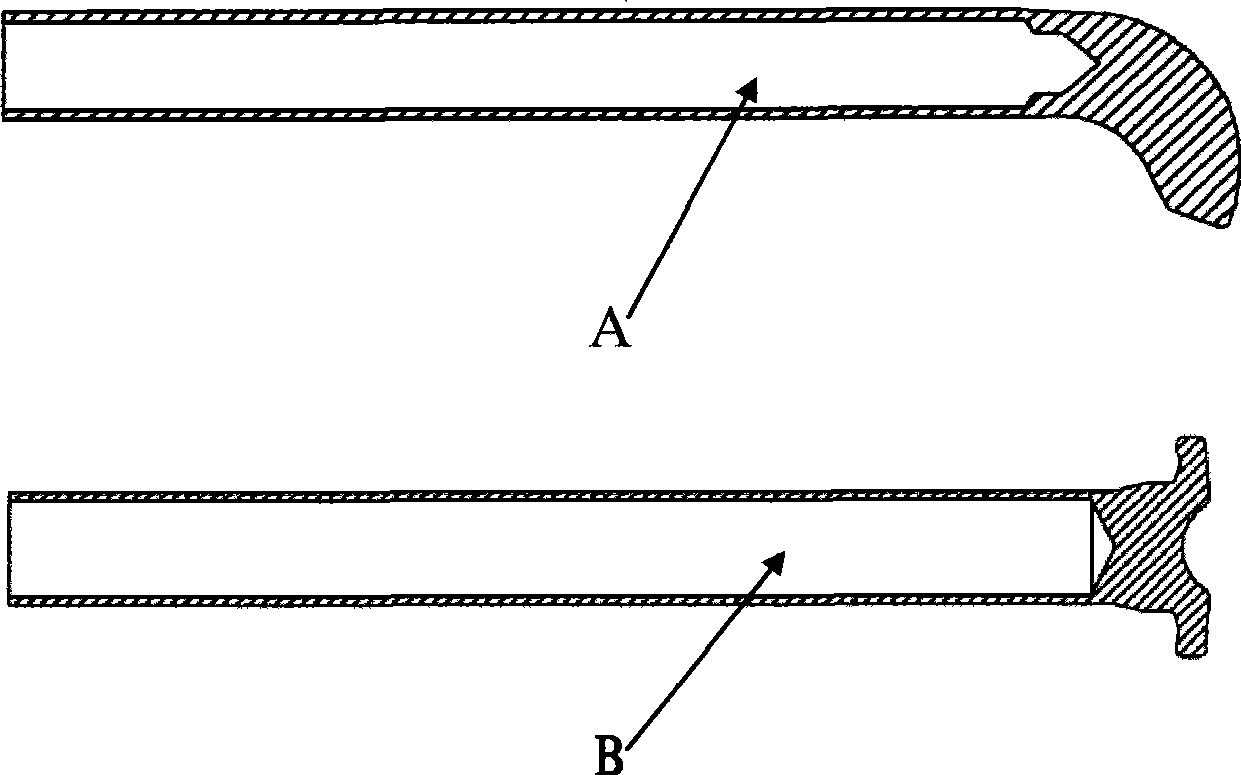

A molding method and bicycle technology, applied in bicycle saddles, bicycle accessories, transportation and packaging, etc., can solve the problems of low product precision, easy desoldering or fracture of welding parts, and poor control of long bottoms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

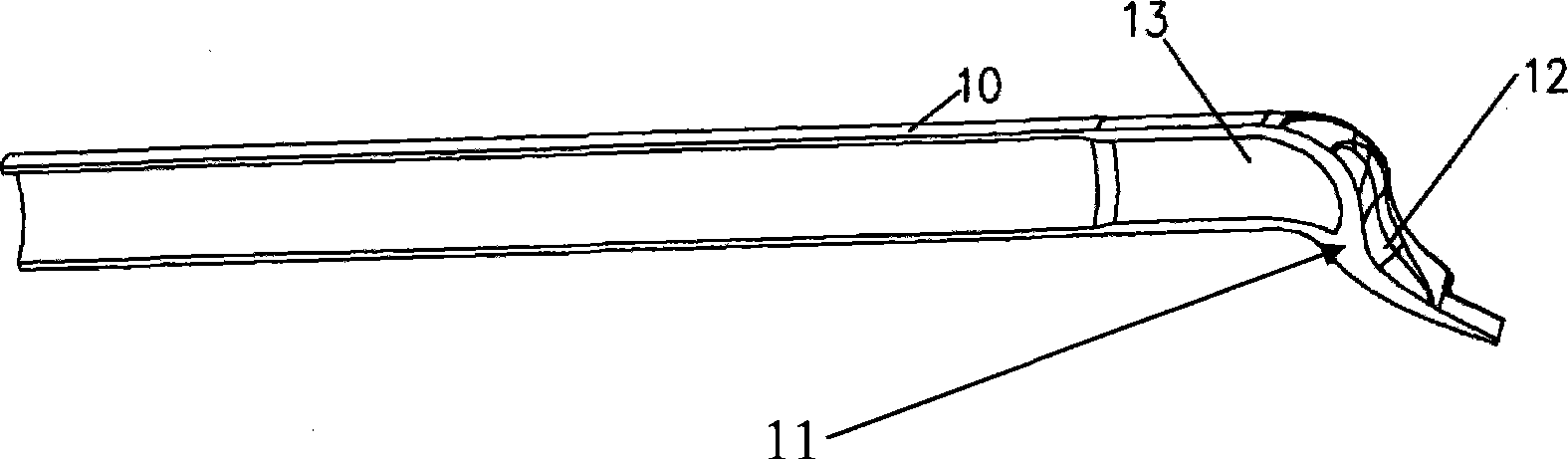

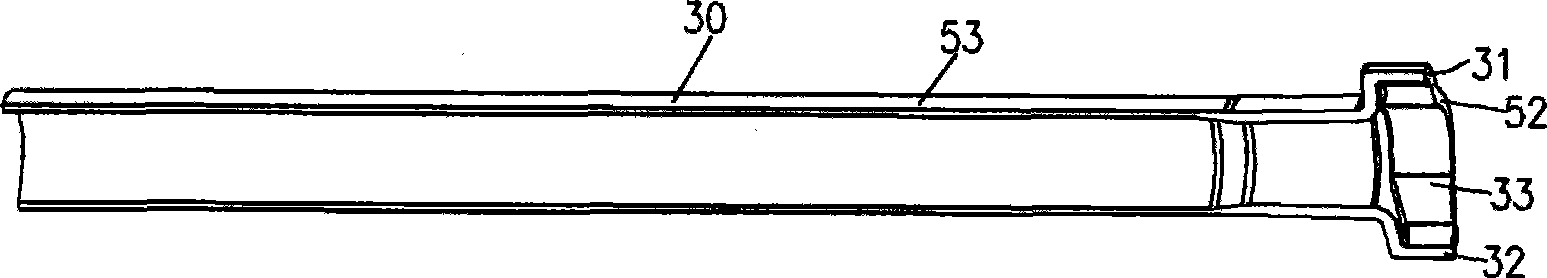

[0030] Such as figure 2 Shown is a structural schematic diagram of the first embodiment of the integrated bicycle metal seat tube. An integrated bicycle metal seat tube includes a vertical pipe body and a horizontal installation part, and the vertical pipe body and the horizontal installation part are integrally formed by metal pipe fittings , The horizontal installation part forms reinforcing ribs 11 , lightening grooves 12 and core-pulling holes 13 . Since the vertical pipe body and the horizontal installation part are integrally formed by metal pipe fittings, the reinforcing ribs 11, lightening grooves 12 and core-pulling holes 13 are formed at the same time, which enhances the compressive strength of the bicycle seat pipe, reduces the weight of the bicycle seat pipe, and improves the bicycle seat pipe. Forming accuracy reduces c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com