Inflatable bag body

A technology of inflatable bags and gas passages, applied in the direction of preventing mechanical damage, packaging of vulnerable items, containers, etc., can solve problems such as damage to cushion air bags, gas leakage, loss of buffer protection, etc., and achieve the effect of enhancing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

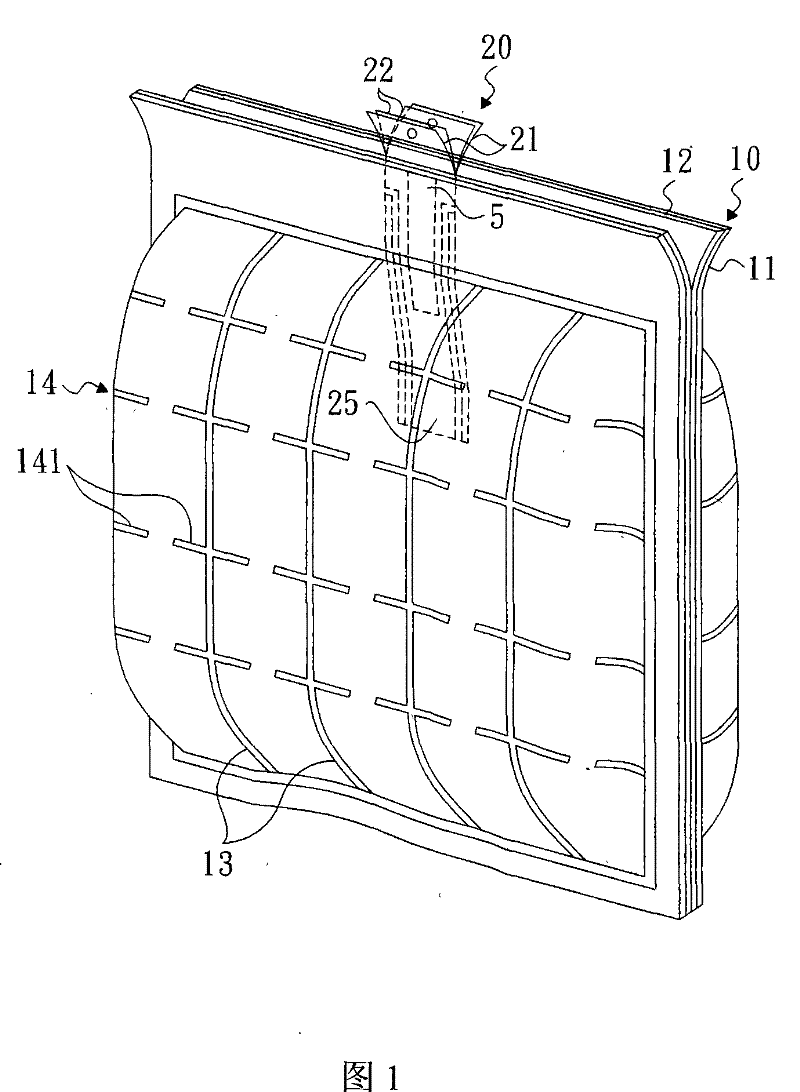

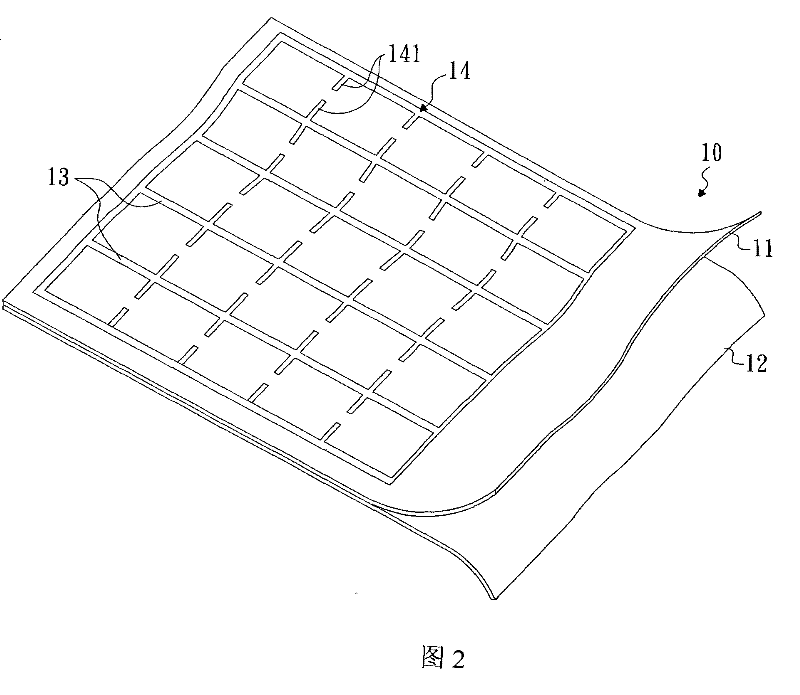

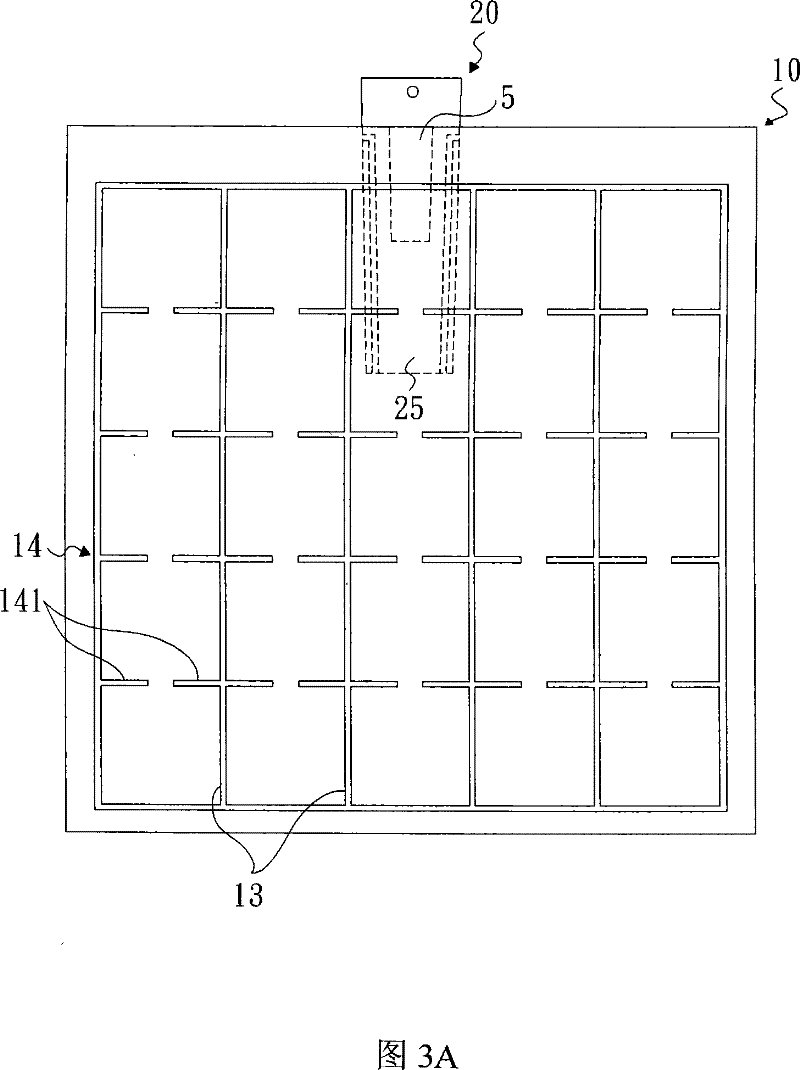

[0030] Fig. 1, Fig. 2, Fig. 3A and Fig. 3B show the inflatable bag body of the first embodiment of the present invention, which includes: two outer membranes 10 stacked up and down, an air chamber 30 and a main air stop valve 20.

[0031] The air chamber 30 is formed between the two outer films 10 by heat-sealing the sides of the outer film 10 , and the number of the air chambers 30 can be changed according to different structures and requirements. Each outer membrane 10 includes a first diaphragm 11 and a second diaphragm 12 stacked up and down, and the first diaphragm 11 and the second diaphragm 12 can be made of the same material, such as polyethylene (polyethylene, PE) , can also be made of different materials, for example, one piece of the first membrane or the second membrane is made of polyethylene, and the other is made of kraft paper. And there is no glue coated between the first diaphragm 11 and the second diaphragm 12, so they will not be glued together. The first ...

no. 2 example

[0036] Figure 4 shows a second embodiment of the present invention. Different from the first embodiment, the main air stop valve 20 of this embodiment only includes two first inner films 21 stacked up and down, and the first heat-resistant material 5 is coated between the two first inner films. For example: printing heat-resistant glue or ink in printing. The first air inlet 24 and the first gas channel 25 are formed between the two first inner films 21 by heat sealing, so that the air chamber 30 communicates with the outside world.

no. 3 example

[0038] Fig. 5, Fig. 6 and Fig. 7 show the third embodiment of the inflatable bag body of the present invention.

[0039] In this embodiment, multiple first heat-sealing lines 13 separate the first membrane 11 and the second membrane 12 into multiple air columns 16, and multiple second heat-sealing lines 14 separate each air column 16 It is divided into a plurality of air column sections 161 , and each air column section 161 on each air column 16 communicates with each other.

[0040] An inflation passage 17 and a plurality of auxiliary air stop valves 18 are also arranged between the first diaphragm 11 and the second diaphragm 12. It is formed by connecting the first diaphragm 11 and the second diaphragm 12. The auxiliary air stop valve 18 includes two auxiliary inner membranes 180 stacked up and down, on which a heat sealing point 18c is formed by means of heat sealing, and the heat sealing point makes the first diaphragm 11 and a piece of auxiliary inner membrane 180 bonded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com