Assembled integrated house component and building method of integrated house

An integrated housing and prefabricated technology, applied in building components, buildings, roofs, etc., can solve the problems of cumbersome installation, complicated process, and unenvironmental construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

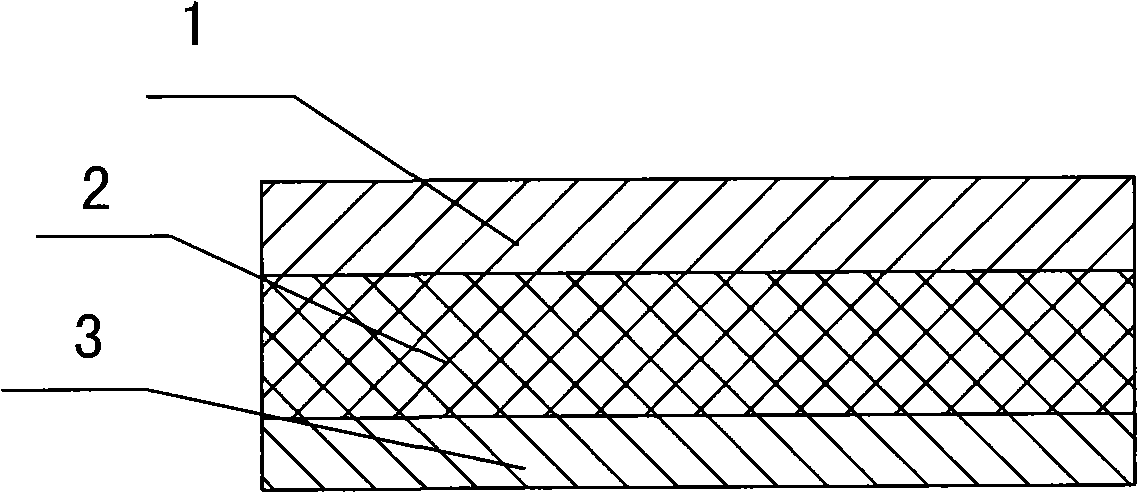

[0066] Such as figure 1 , The outer wall panel is finally formed by compounding (by bonding) the outer panel 1, the inner panel 3, and the insulating filling layer 2 between the outer panel and the inner panel.

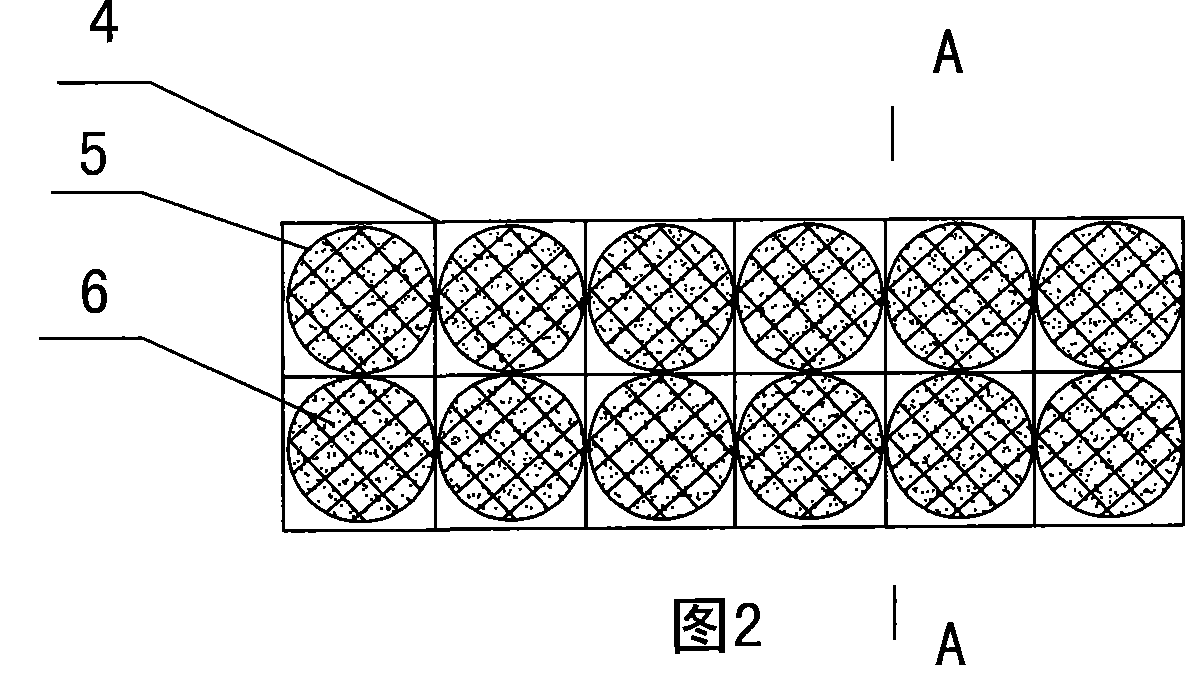

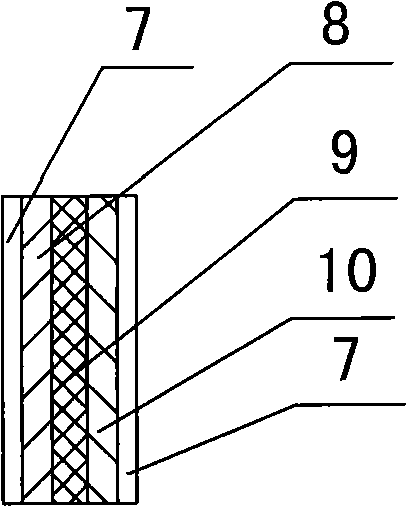

[0067] As shown in Figure 2, image 3 The floor deck is composed of a reinforced frame body 4, an upper coating panel 8, a lower coating panel 10, a honeycomb filling material 9 and a waterproof layer 7. The well-shaped lattice of the reinforcing frame body 4 is inlaid with a honeycomb filling material 9, and the frame body and honeycomb filling The two sides of the material are compounded with the upper coating panel 8 and the lower coating panel 10 respectively, and the surfaces of the upper coating panel and the lower coating panel are combined with a waterproof layer 7 . The honeycomb filling material 9 can be a hexagonal, corrugated or round tubular honeycomb body 5, and the honeycomb cavity is filled with the heat-insulating and sound-insulating material 6.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com