Plane display device, its combined outer frame and manufacturing method

A flat-panel display and manufacturing method technology, applied to instruments, identification devices, nonlinear optics, etc., can solve the problems of unsatisfactory tightness and difficulty in preventing dust from invading the internal components of a display module, and achieve the effect of preventing dust intrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The invention provides a combined outer frame of a flat panel display module, a flat panel display using the combined outer frame and a manufacturing method thereof. In a preferred embodiment, the joint design of the outer frame assembly of the flat panel display of the present invention is applied to various flat panel displays, including liquid crystal displays, plasma displays (Plasma Display Panel, PDP), field emission displays (Field Emission Display, FED) and organic Light Emitting Display (Organic Light Emitting Display, OLED), etc.

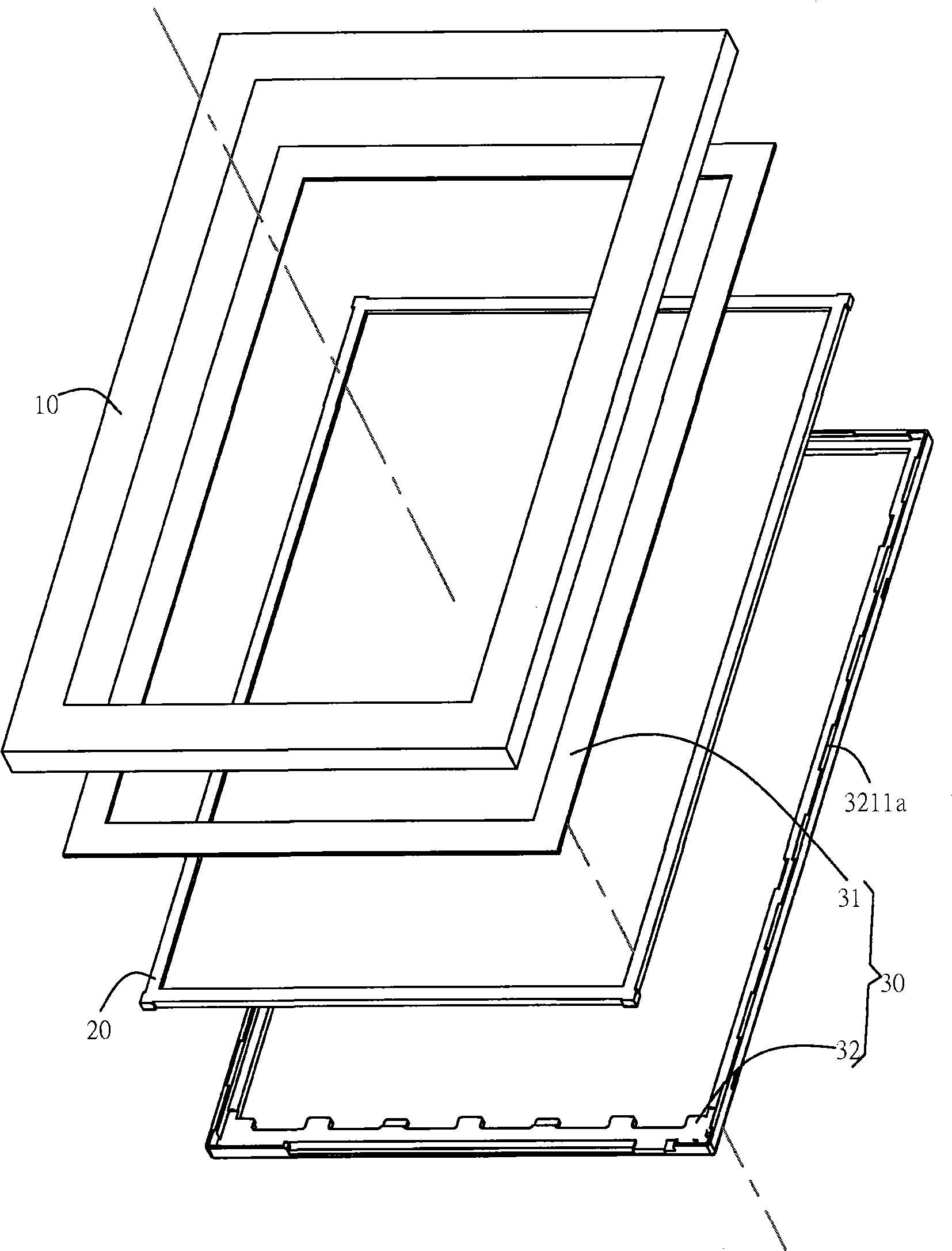

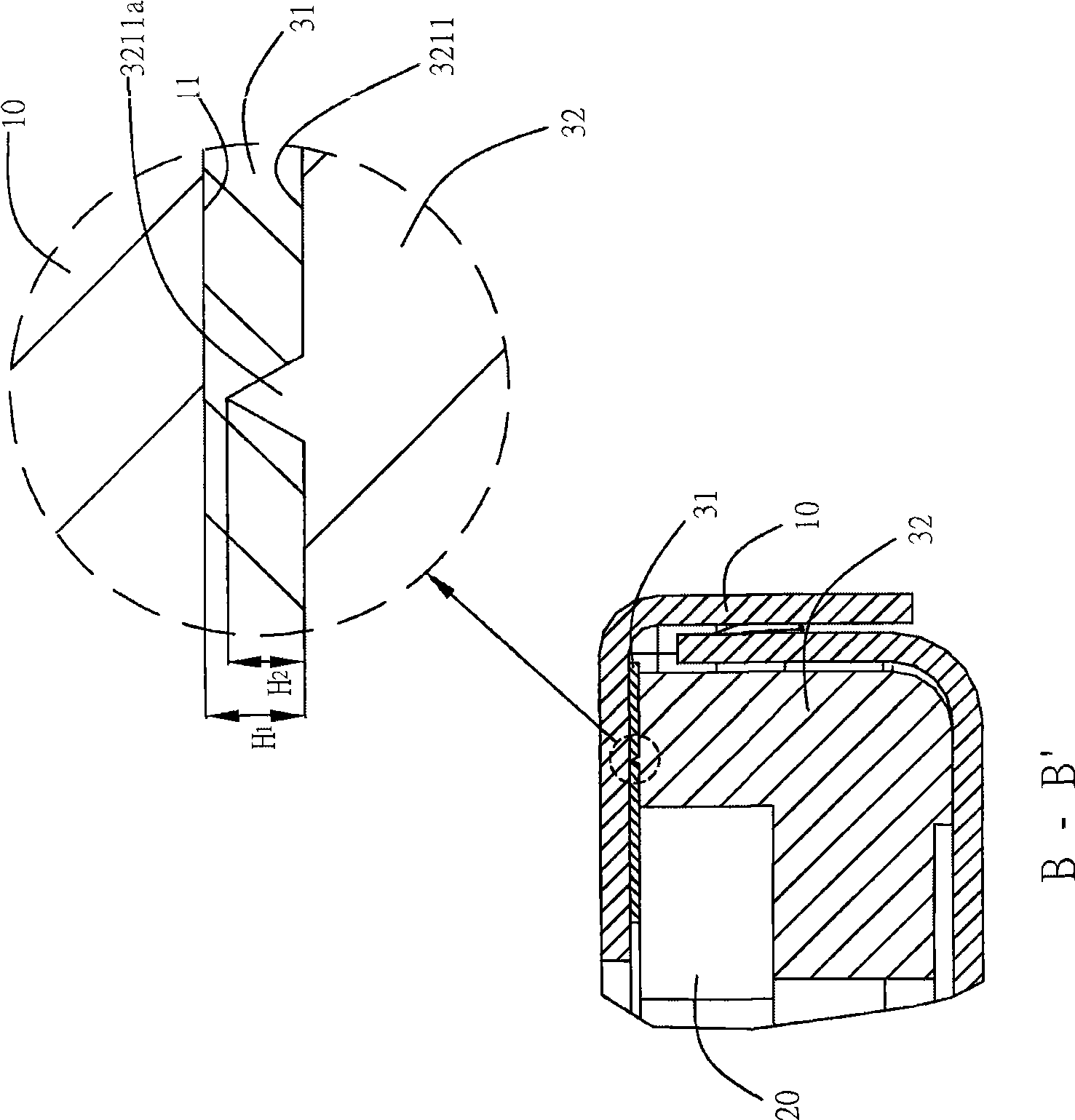

[0028] figure 1 It is a three-dimensional exploded view of an embodiment of the flat panel display of the present invention. Such as figure 1 As shown, the flat panel display includes a front frame 10 , a display panel 20 and a backlight module 30 . The front frame 10 includes an inner contact surface 11 (not shown) facing the inner side. The front frame 10 is preferably a frame body with a hollowed out central portion, and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com