Thin-film transistor array substrate

A thin-film transistor and array substrate technology, which is applied in the field of thin-film transistor array substrates, can solve the problems of reducing light transmittance, discontinuous misdirection defects, etc., and achieve the effects of avoiding light leakage, strong dumping force, and small aperture ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The aforementioned and other technical contents, features and functions of the present invention will be clearly presented in the following detailed description of the embodiments with reference to the drawings. The directional terms mentioned in the following embodiments, such as: up, down, left, right, front or back, etc., are only directions referring to the attached drawings. Accordingly, the directional terms are used to illustrate and not to limit the invention.

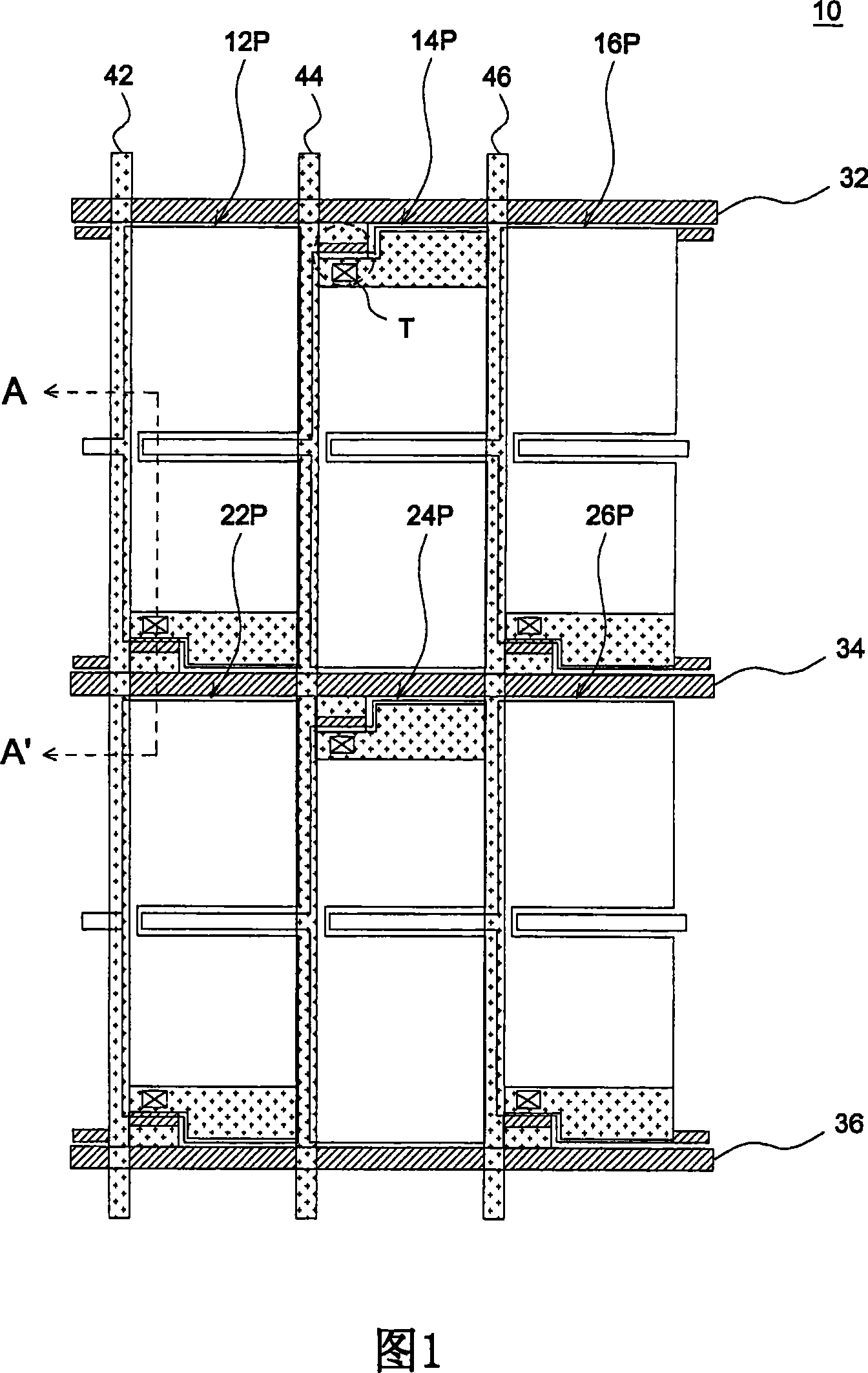

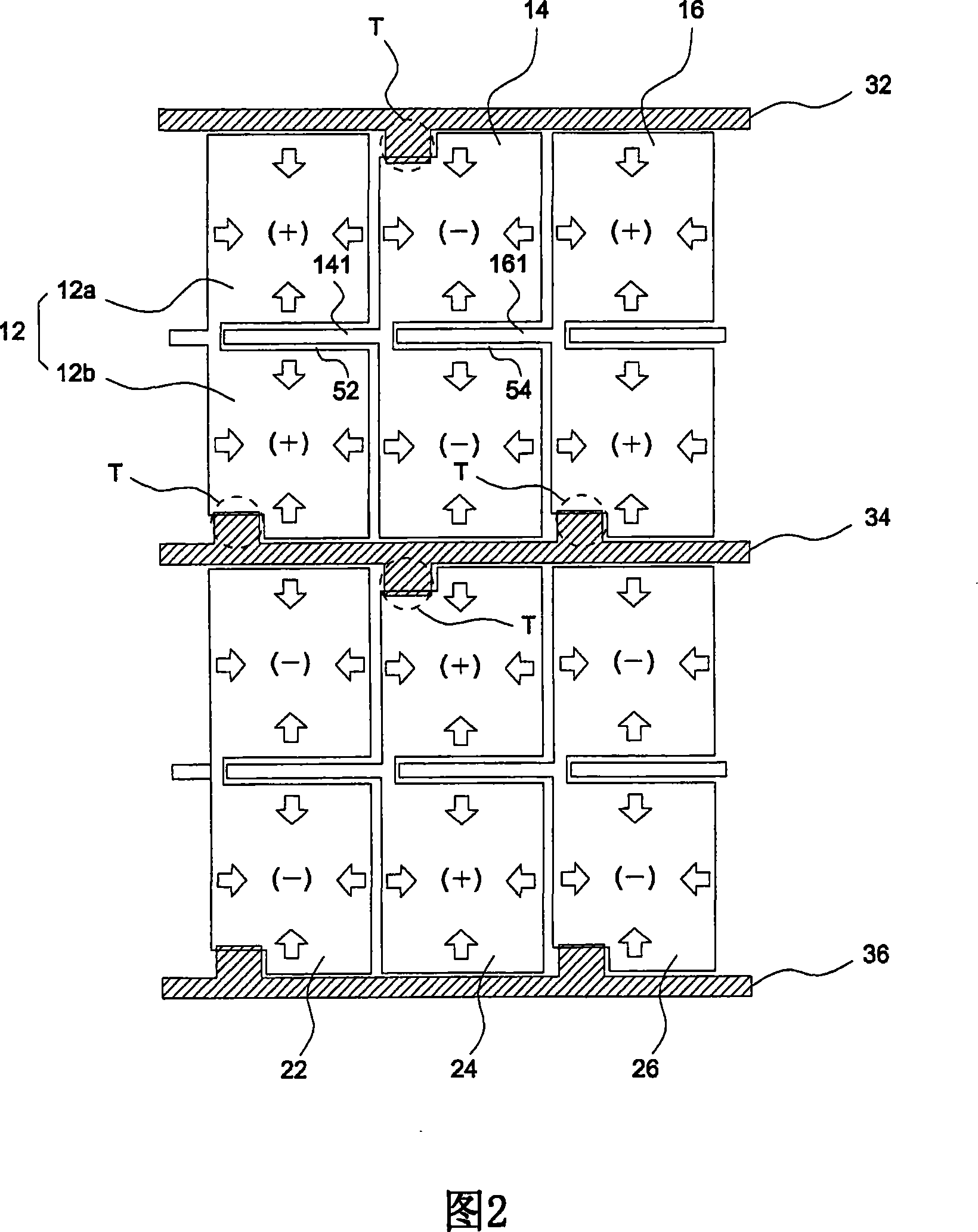

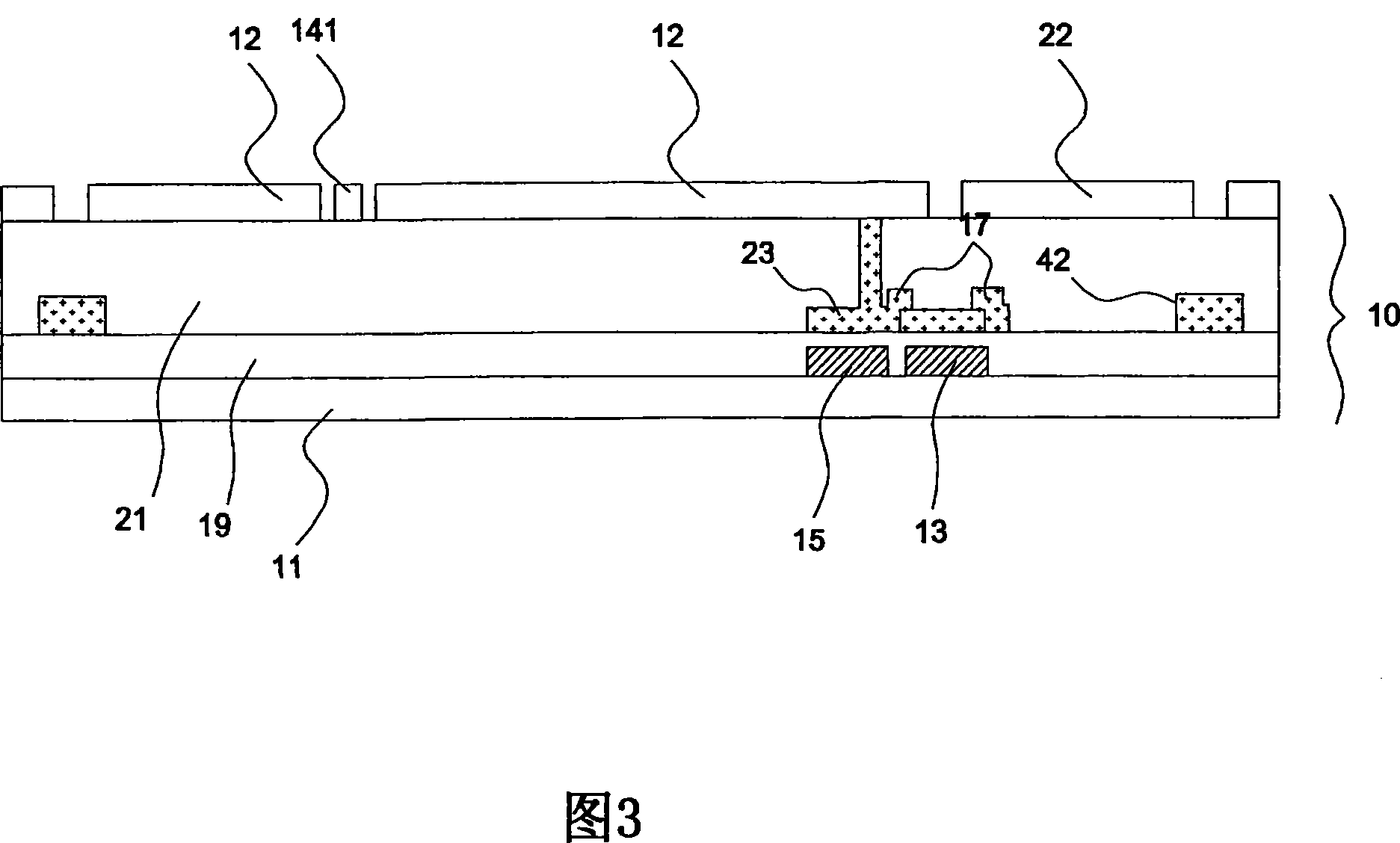

[0049] figure 1 According to an embodiment of the present invention, a schematic plan view of a thin film transistor array substrate 10 is shown. Such as figure 1As shown, a plurality of scan lines 32, 34, 36 parallel to each other and data lines 42, 44, 46 parallel to each other are formed on an insulating substrate (not shown), and two adjacent scan lines are orthogonal to the two phases. Adjacent data lines encircle a pixel unit distribution area, such as the active element of thin film transisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com