Battery wire laying method for electric vehicle

A layout method and technology for electric vehicles, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of high cost, high one-time input cost of batteries, and performance that cannot meet social needs, and achieve low use costs, various Excellent performance and low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Taking the 144V, 72AH lead-acid battery of an electric vehicle as an example, a description of the implementation is made:

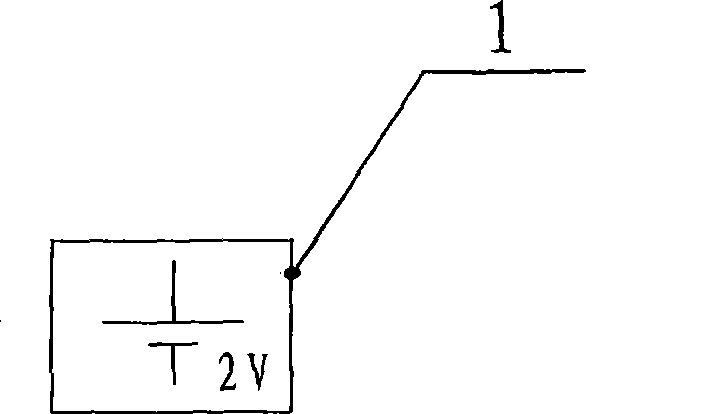

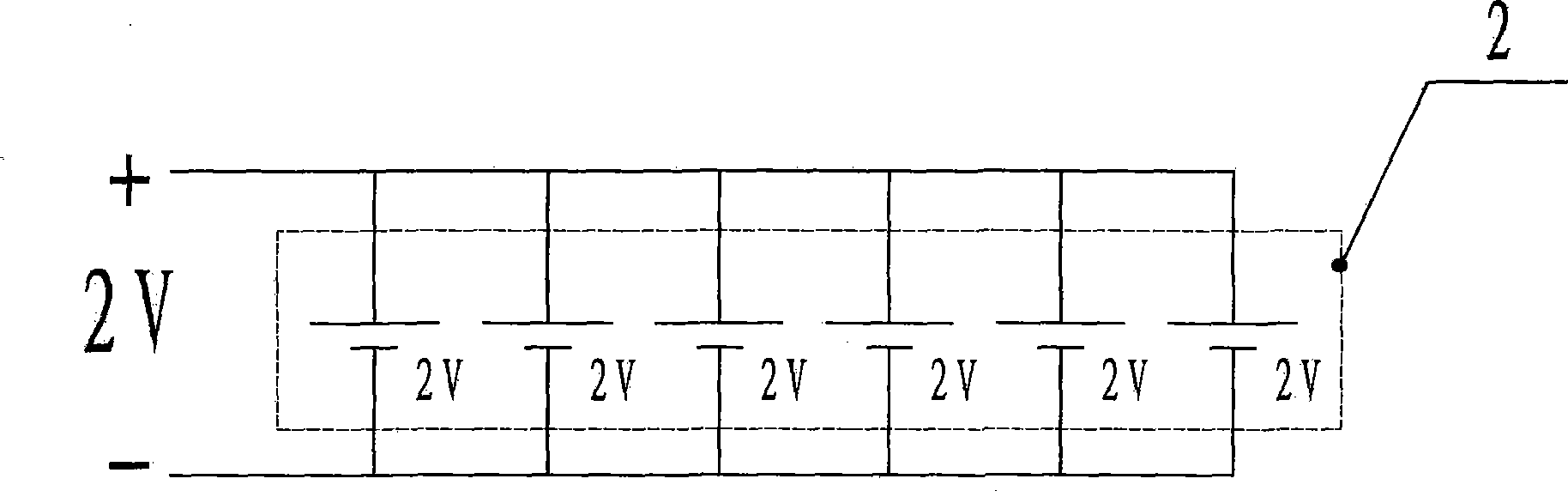

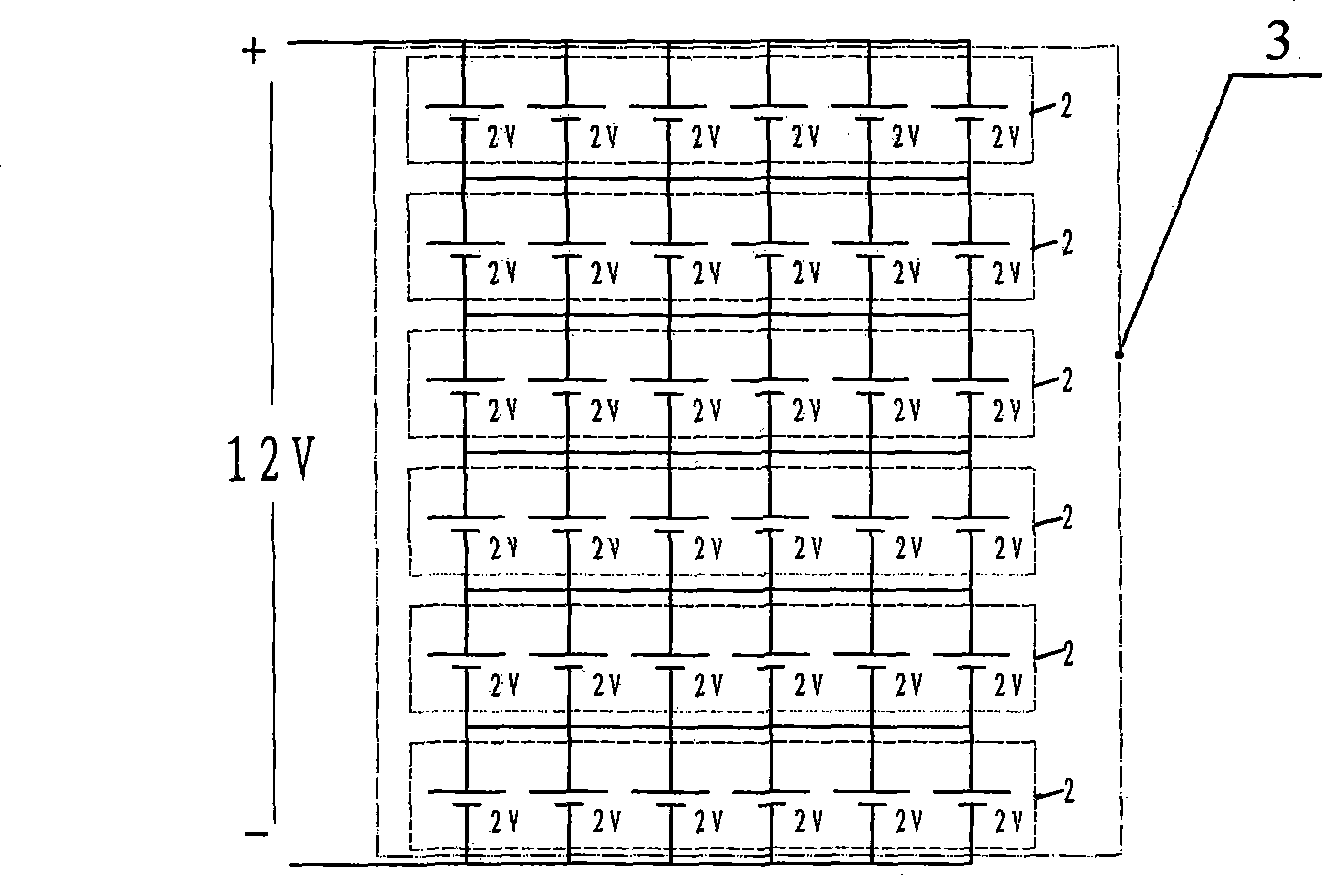

[0019] Use 2V, 12AH lead-acid battery as a single cell battery (such as figure 1 As shown), six 2V, 12AH lead-acid batteries 1 are connected in parallel to form a 2V, 72AH parallel battery pack 2 (such as figure 2 As shown), six groups of parallel battery packs 2 are connected in series to form a 12V, 72AH unit series-parallel matrix battery pack 3 (such as image 3 As shown), each 2V lead-acid battery is connected to each other; then the series-parallel matrix battery pack 3 is distributed to twelve parts of the chassis of the vehicle to achieve the balance of the center of gravity of the chassis, and the twelve units are connected in series and parallel The matrix-shaped storage battery pack 3 forms the required 144V, 72AH storage battery pack 4 (such as Figure 4 Shown), the storage battery pack 4 is to provide the power supply of the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com