Grape soil-burry cultivation method without off-grape trellis in soil-burry winter-proofing region

A grape and horizontal technology, applied in the fields of cultivation, plant protection cover, application, etc., can solve the problems of damage to grape quality by branches and vines, labor and time consuming, and cost increase, and achieve the goal of improving cold resistance, reducing production costs, and reducing labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

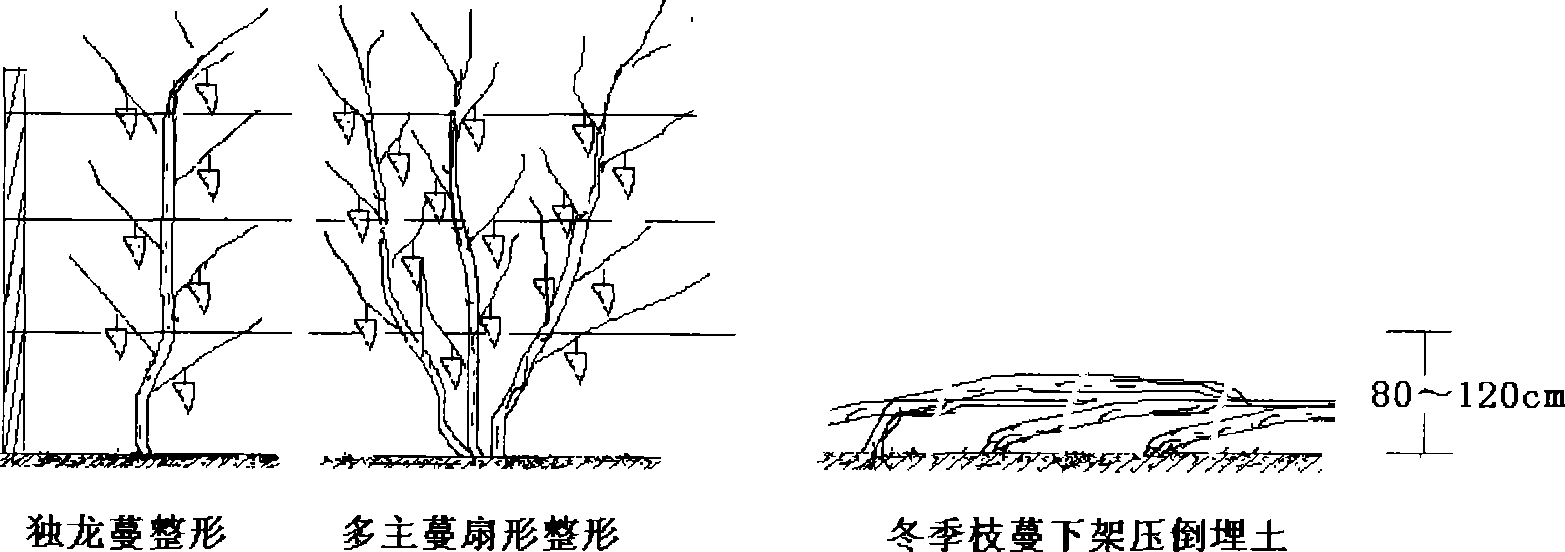

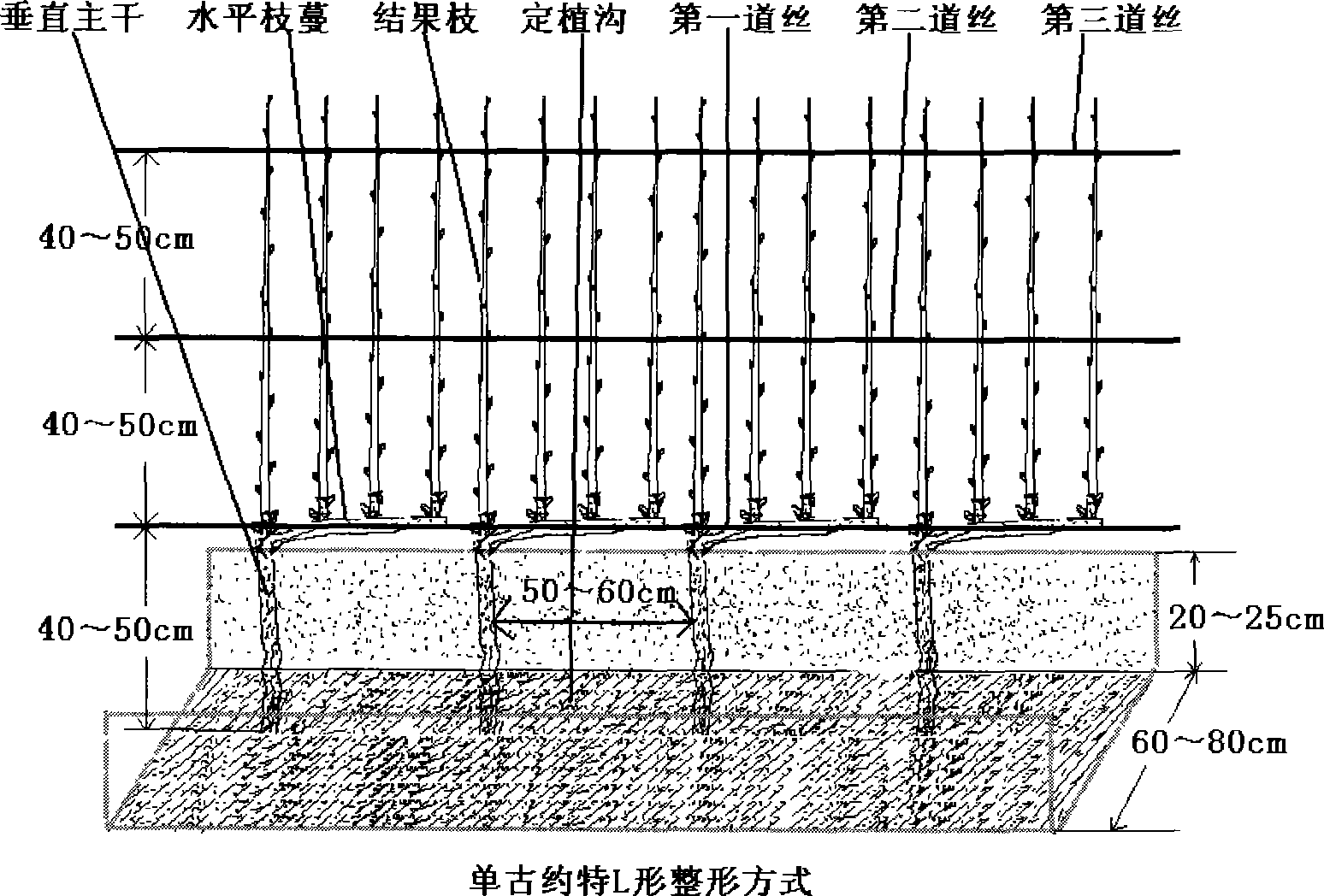

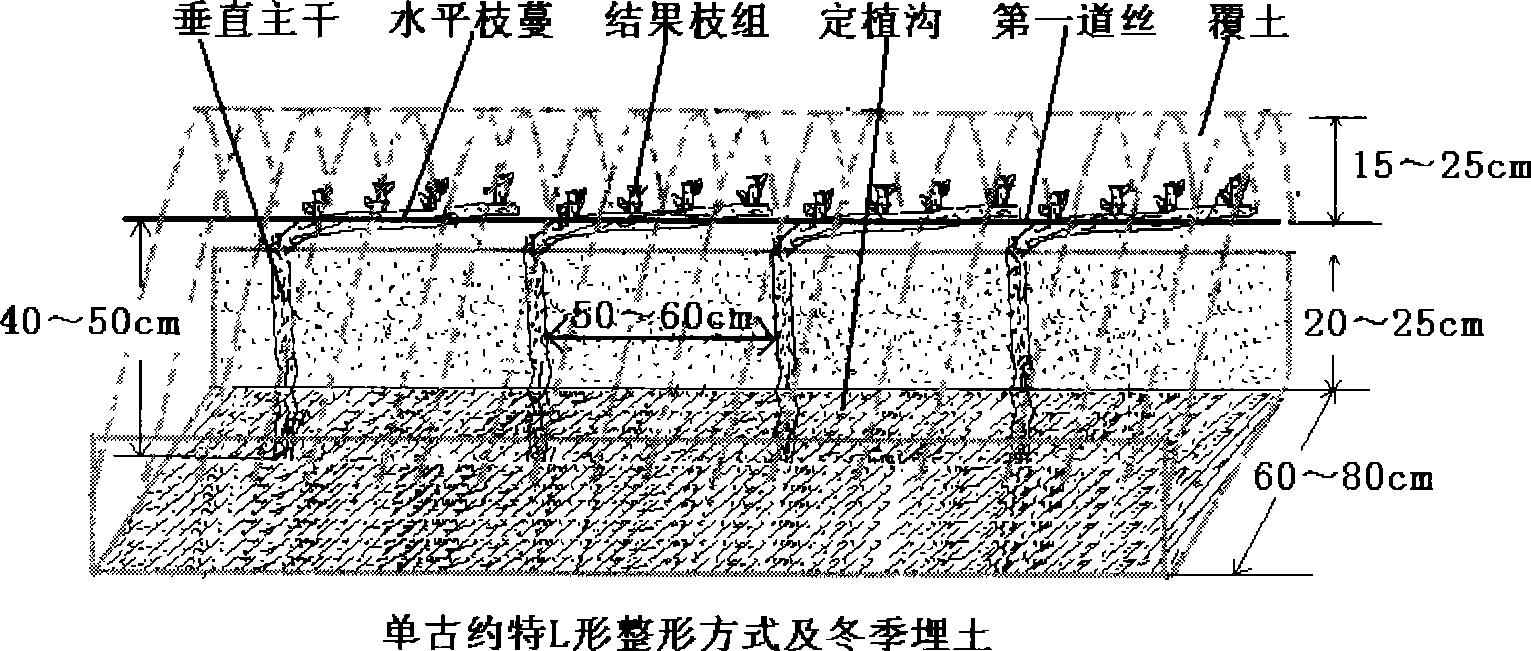

[0016] Embodiment 1 (adopting single Guyot L-shape mode shaping):

[0017] First, dig a planting ditch with a width of 60 to 80 cm and a depth of 70 to 100 cm according to the row spacing of 3.0 to 3.5 m, and apply 5 to 8 m per mu when opening the ditch 3 The organic fertilizer is mixed with the surface soil and placed on the west side (north-south row) or south side (east-west row) of the planting ditch, and the core soil is placed on the other side. Then fill the mixed soil into the planting ditch, and then fill in part of the core soil to keep the depth of the planting ditch at 20-25cm. Grape seedlings are planted at a plant spacing of 50-60 cm. The first and second years are managed as traditional grapes, and a strong branch is selected for cultivation, and the depth of the ditch is always kept at 20-25 cm. After the leaves fall in the autumn of the second year, use a single Guyot L-shaped method with a trunk height of 40-50 cm for plastic surgery (see attached figure 2...

Embodiment 2

[0018] Embodiment 2 (adopt double Guyot L shape (or T shape) shaping mode):

[0019] First, dig a planting ditch with a width of 60 to 80 cm and a depth of 70 to 100 cm according to the row spacing of 3.0 to 3.5 cm, and apply 5 to 8 M per mu when opening the ditch 3 The organic fertilizer is mixed with the surface soil and placed on the west side (north-south row) or south side (east-west row) of the planting ditch, and the core soil is placed on the other side. Then fill the mixed soil into the planting ditch, and then fill in part of the core soil to keep the depth of the planting ditch at 20-25cm. Grape seedlings are planted at a plant spacing of 60-100 cm. In the first and second years, the traditional grapes are managed normally, and two strong branches and tendrils are selected for key cultivation, and the furrow depth is always kept at 20-25 cm. After the leaves fall in the autumn of the second year, the double Guyot L-shape (or T-shape) plastic method with a trunk hei...

Embodiment 3

[0020] Embodiment 3 (adopting the cup shape shaping mode):

[0021] First, dig a planting ditch with a width of 60 to 80 cm and a depth of 70 to 100 cm according to the row spacing of 3.0 to 3.5 m, and apply 5 to 8 m per mu when opening the ditch 3 The organic fertilizer is mixed with the surface soil and placed on the west side (north-south row) or south side (east-west row) of the planting ditch, and the core soil is placed on the other side. Then fill the mixed soil into the planting ditch, and then fill in part of the core soil to keep the depth of the planting ditch at 20-25cm. Grape seedlings are planted at a plant spacing of 60-100 cm, and the first and second years are managed normally according to traditional grapes, and a strong branch is selected for cultivation, and the depth of the ditch is always kept at 20-25 cm. After the leaves fall in autumn of the second year, short pruning is adopted at the trunk height of 40 to 45 cm, and in the third year, 3 to 5 branche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com