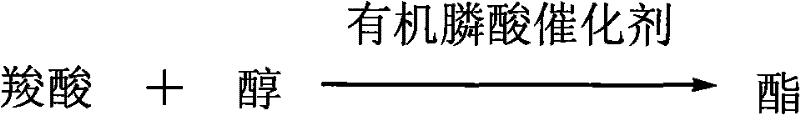

Application of organic phosphonic acid as esterification reaction catalyst

A technology for organic phosphonic acid and esterification, which is applied in the direction of organic compound/hydride/coordination complex catalyst, organic compound preparation, physical/chemical process catalyst, etc. , post-processing troubles and other problems, to achieve the effect of reducing the use cost, wide source and cheap price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

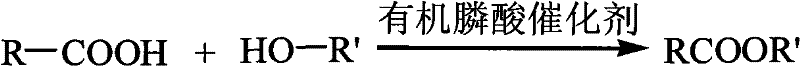

[0015]

[0016] R=CH 3 -, R'=-CH 2 CH 2 CH 2 CH 3 , the catalyst is butylphosphonic acid, the esterification time is 50min, and the esterification rate is 94%.

Embodiment 2

[0018]

[0019] R=CH 3 CH 2 CH 2 -, R'=-CH 2 CH 2 CH 2 CH 3 , the catalyst is butylphosphonic acid, the esterification time is 2h, and the esterification rate is 97%.

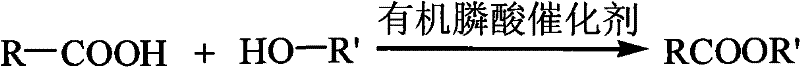

Embodiment 3

[0021]

[0022] R=CH 3 -, R'=-CH 2 CH 2 CH(CH 3 ) 2 , the catalyst is 1-methyl-1-hydroxypropionic acid, the esterification time is 80min, and the esterification rate is 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com