Existing line three-dimensional restriction measuring method

A measurement method, existing wired technology, applied in the field of measurement, achieves the effect of simple operation, good adaptability to environment and climate conditions, and high measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

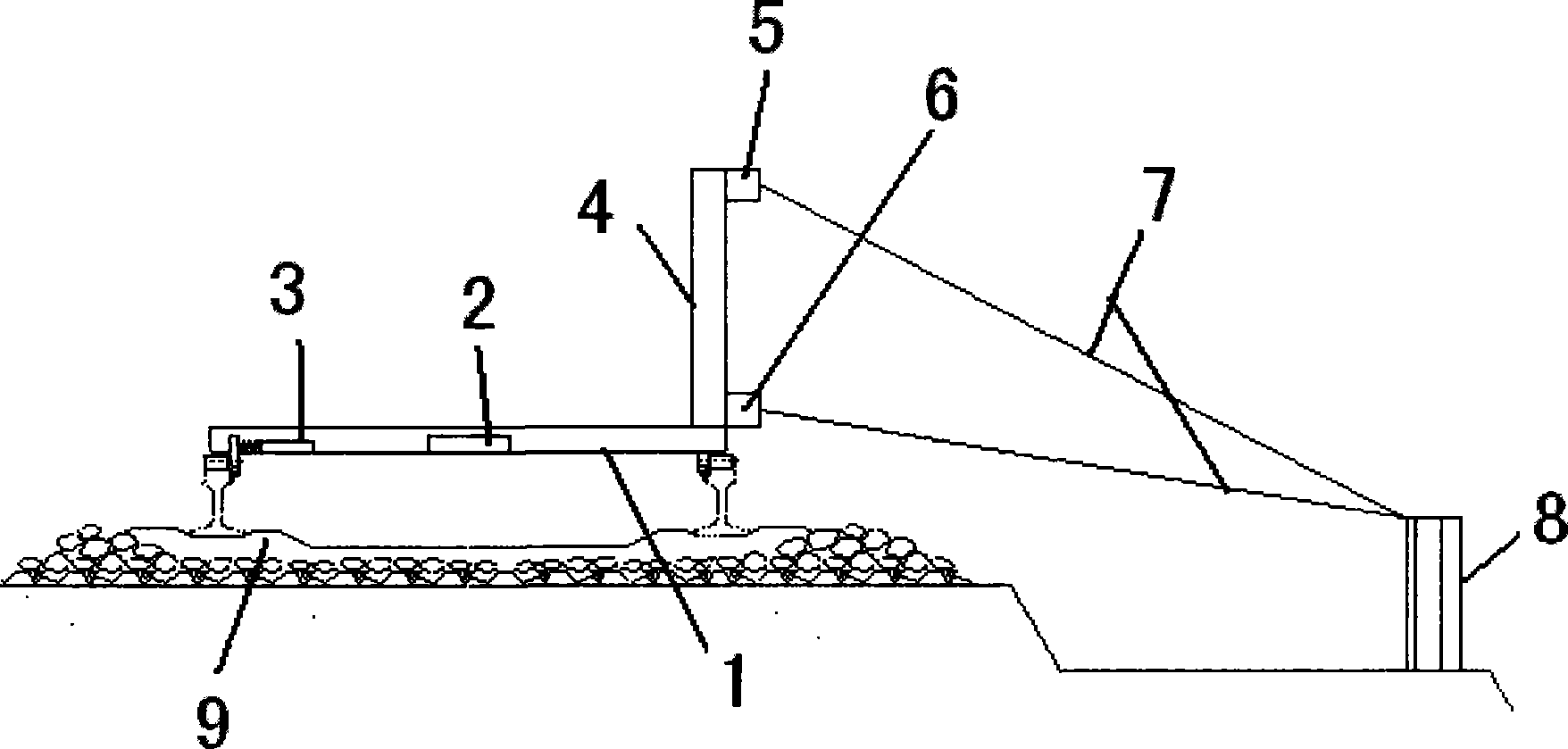

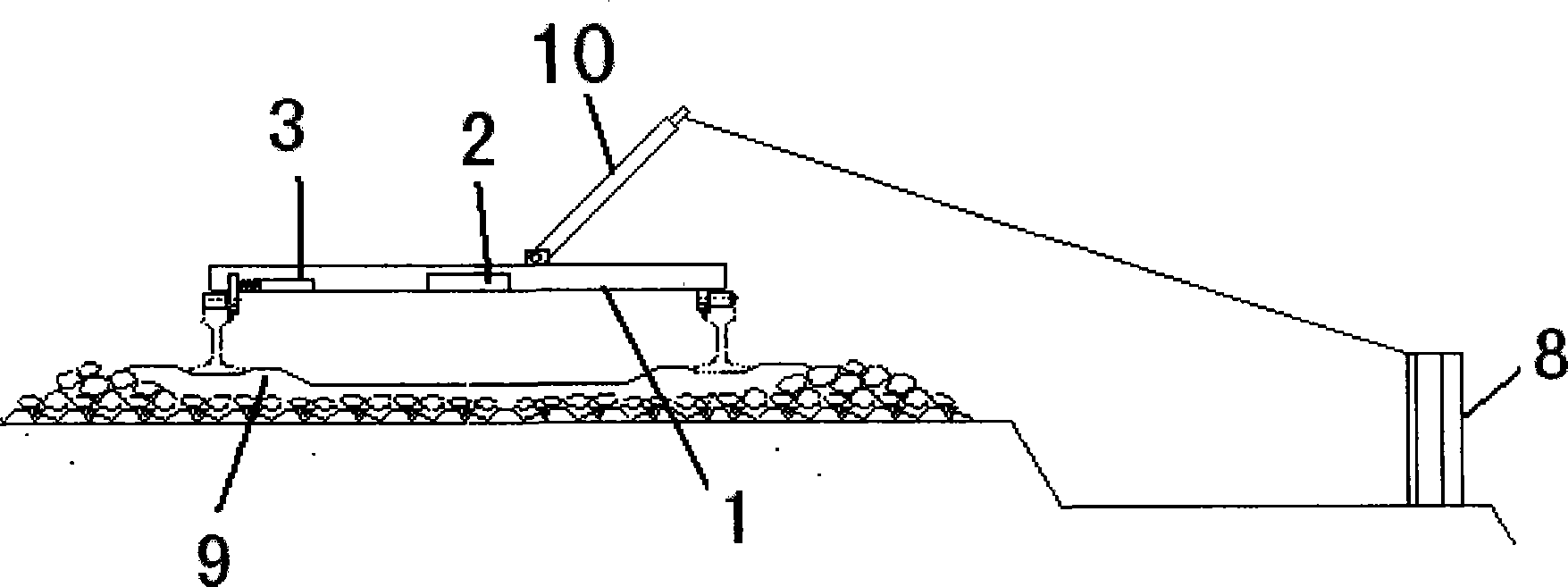

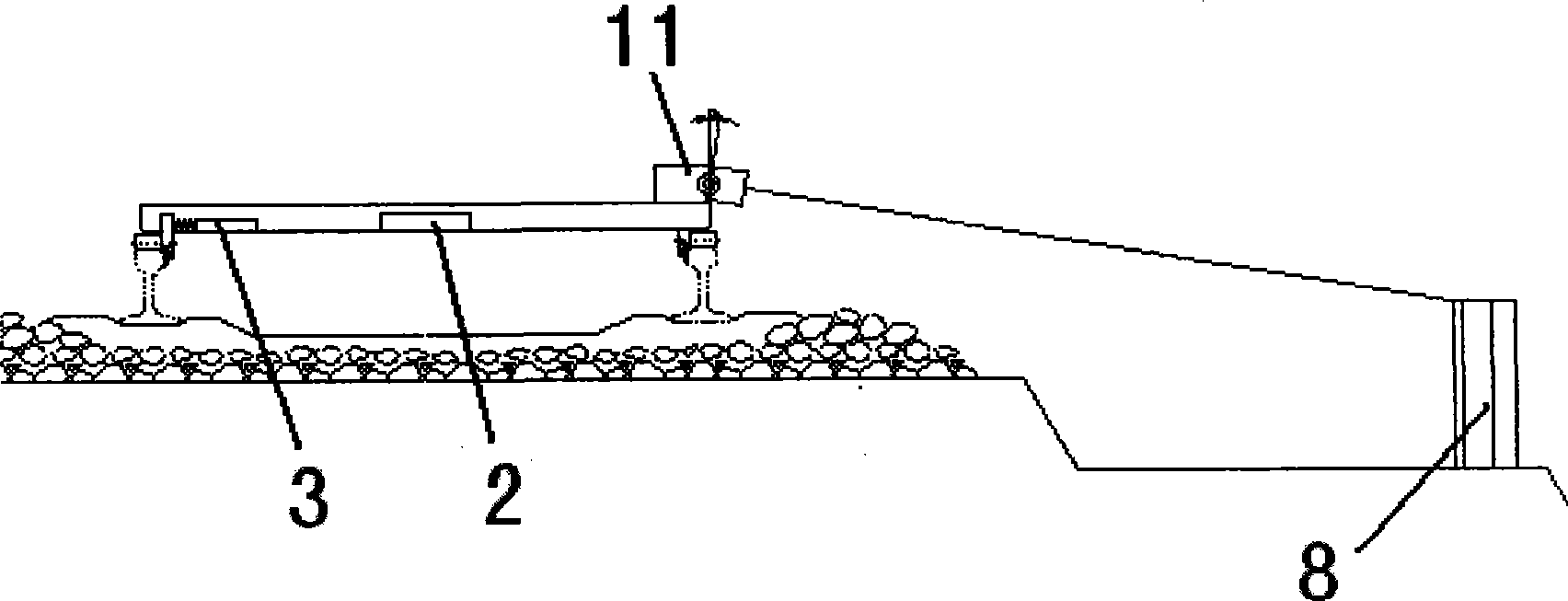

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention is realized in this way, and it comprises track inspection trolley 1, horizontal measuring device 2, gauge measuring device 3, restraint measuring pillar 4, upper pull-wire type displacement sensor 5, pull-down wire type displacement sensor 6, measuring line 7. Track constraint pile 8, track 9 constraint measurement pendulum 10, constraint measurement rotary head 11, laser distance measuring sensor 12, characterized in that track constraint pile 8 is arranged along the railway line, rail inspection trolley 1 is placed on track 9, rail The middle end of the inspection trolley 1 is connected to the horizontal measuring device 2, one end of the rail inspection trolley 1 is connected to the gauge measuring device 3, the other end of the rail inspection trolley 1 is connected to the upright restraint measurement pillar 4, and the upper and lower ends of the restraint measurement pillar 4 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com