Piston sealing structure of vertical non-lubrication piston compressor

A sealing structure and non-lubricating technology, which is applied in the direction of mechanical equipment, variable displacement pump components, machines/engines, etc., can solve the problems of increasing manufacturing difficulty and manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

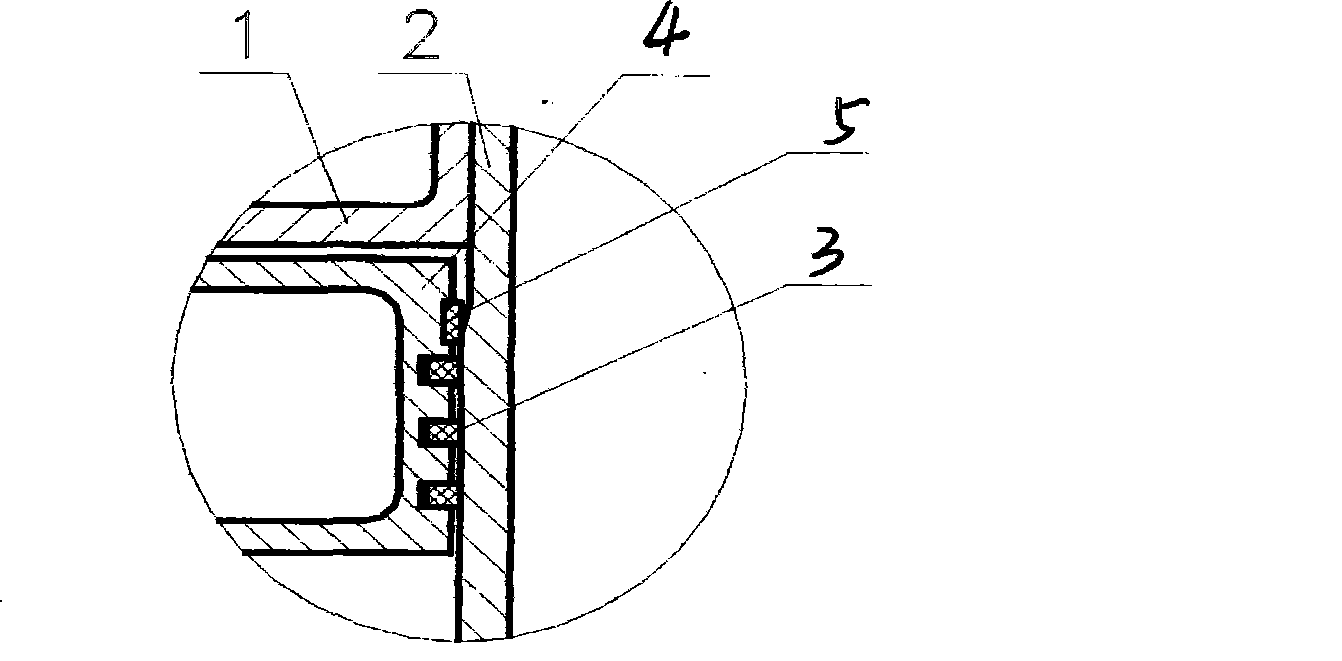

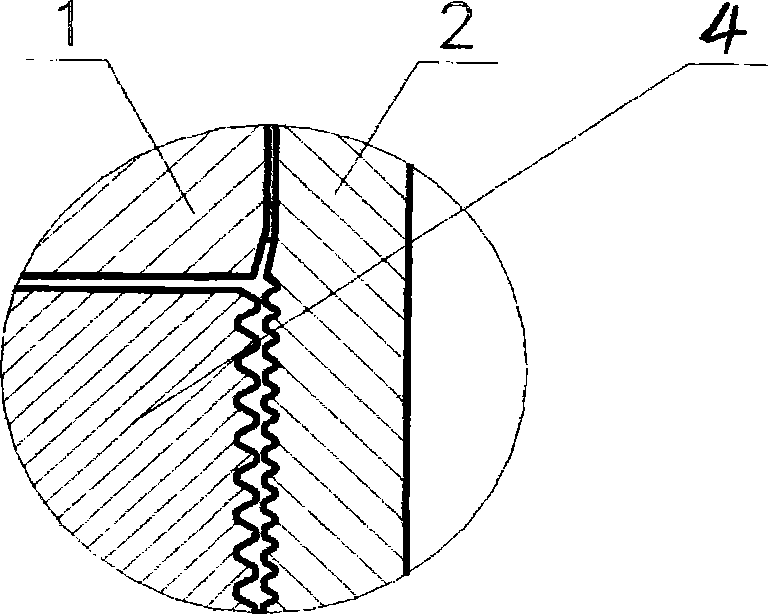

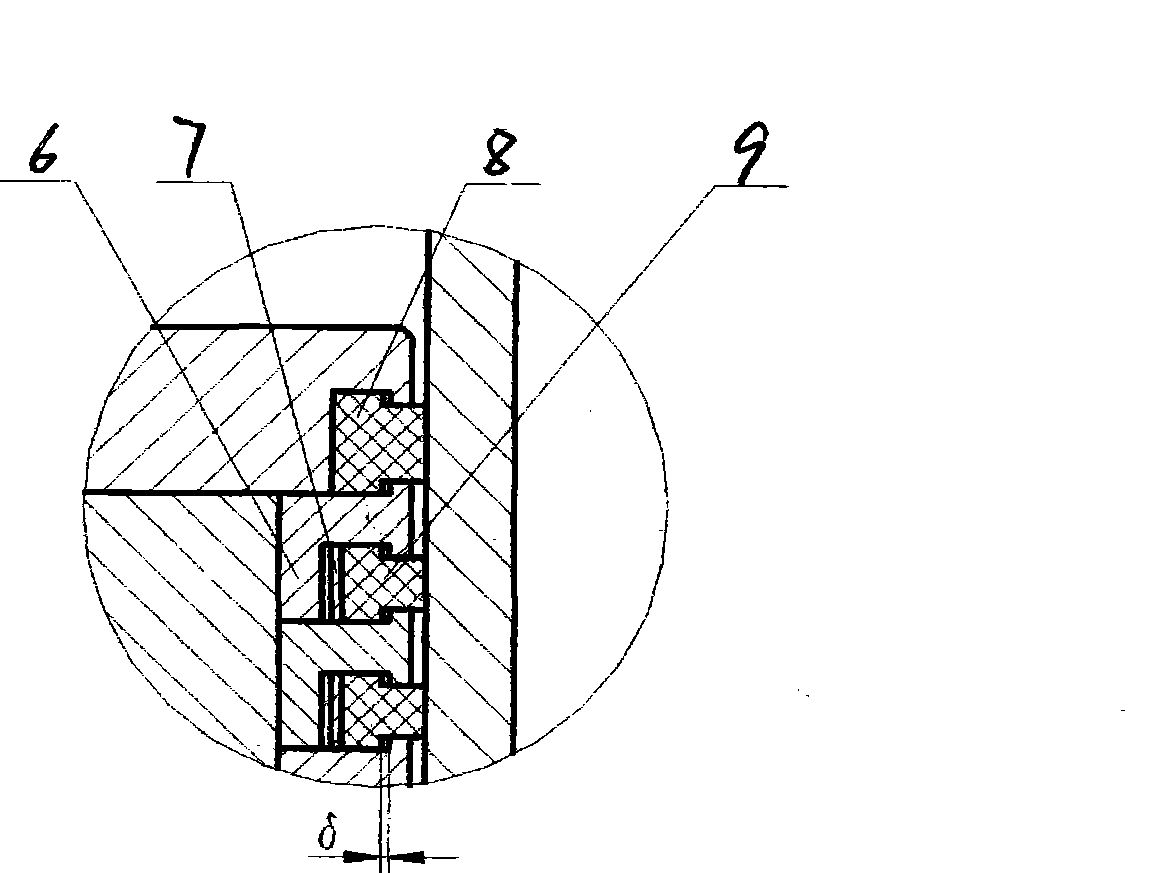

[0020] like Figure 4 As shown, embodiment 1: the present invention includes a guide ring 5 and a piston ring 3 sleeved on the piston 4, and is characterized in that a guide ring 5 is arranged at the active end of the piston 4, and on the outer ring of the guide ring 5 Machining with labyrinth slots. Being provided with a guide ring at the active end of the piston means that a guide ring is sleeved on the upper peripheral surface of the cylindrical piston 4 .

[0021] The thickness of the guide ring 5 is greater than that of conventional guide rings. Between the guide ring 5 and the cylinder 2, there is a thermal expansion gap to ensure that the guide ring not only acts as a guide but also plays a throttling role, that is, to ensure that the guide ring maintains a small gap with the cylinder under working conditions. The guide ring 5 and the piston ring 3 are filled with polytetrafluoroethylene materials. The guide ring 5 is an integral shrink-fit guide ring. The labyrinth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com