Radiant panel thermometer detection apparatus and method for continuous annealing furnace

A continuous annealing furnace and detection device technology, applied in the direction of measuring devices, thermometers, electrical devices, etc., can solve the problems of high operating temperature, offline calibration, etc., achieve good overall sealing, and solve the effect of offline calibration

Inactive Publication Date: 2009-07-22

CISDI ENG CO LTD

View PDF1 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The use of a reasonable transmission structure solves the problem of high operating temperature; solves the problem of off-line calibration of the radiant panel thermometer; can control the temperature of the radiant panel when the radiant panel thermometer fails; protection of the device

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

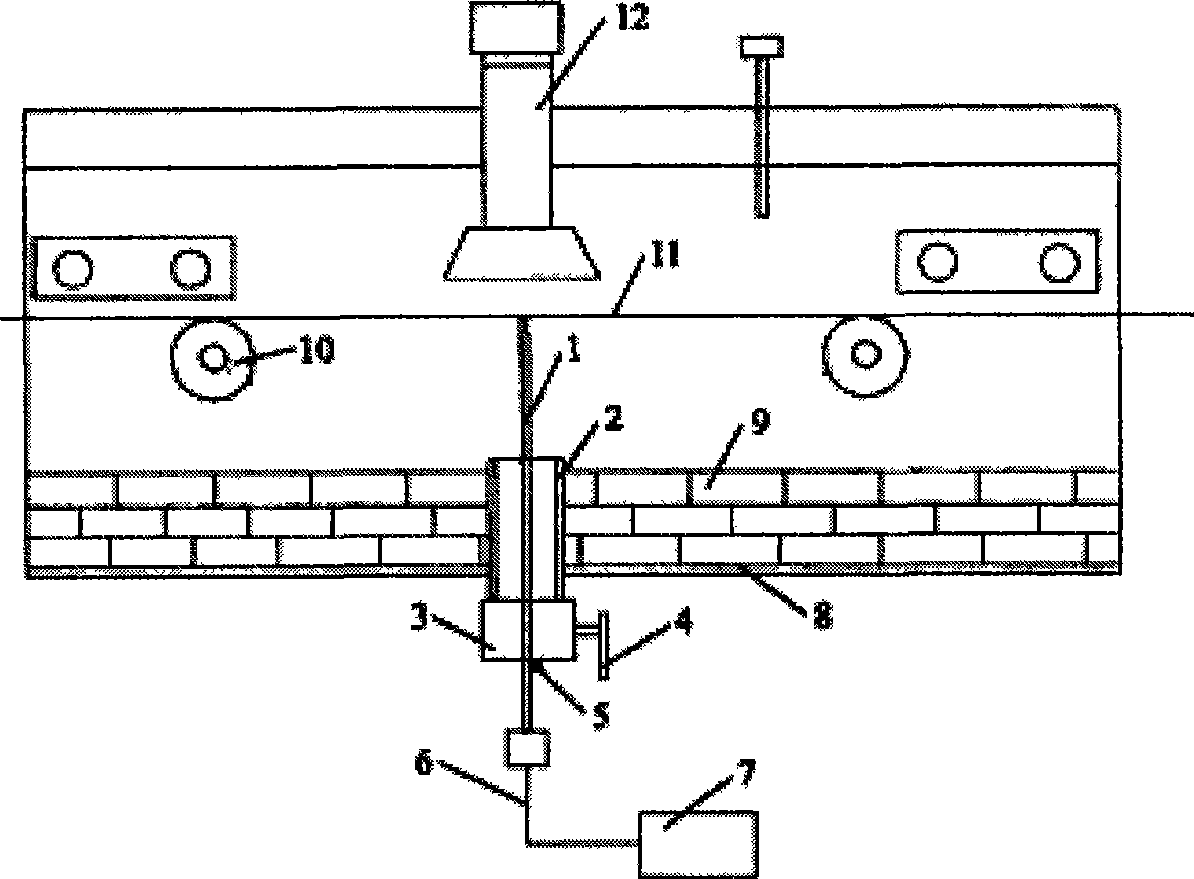

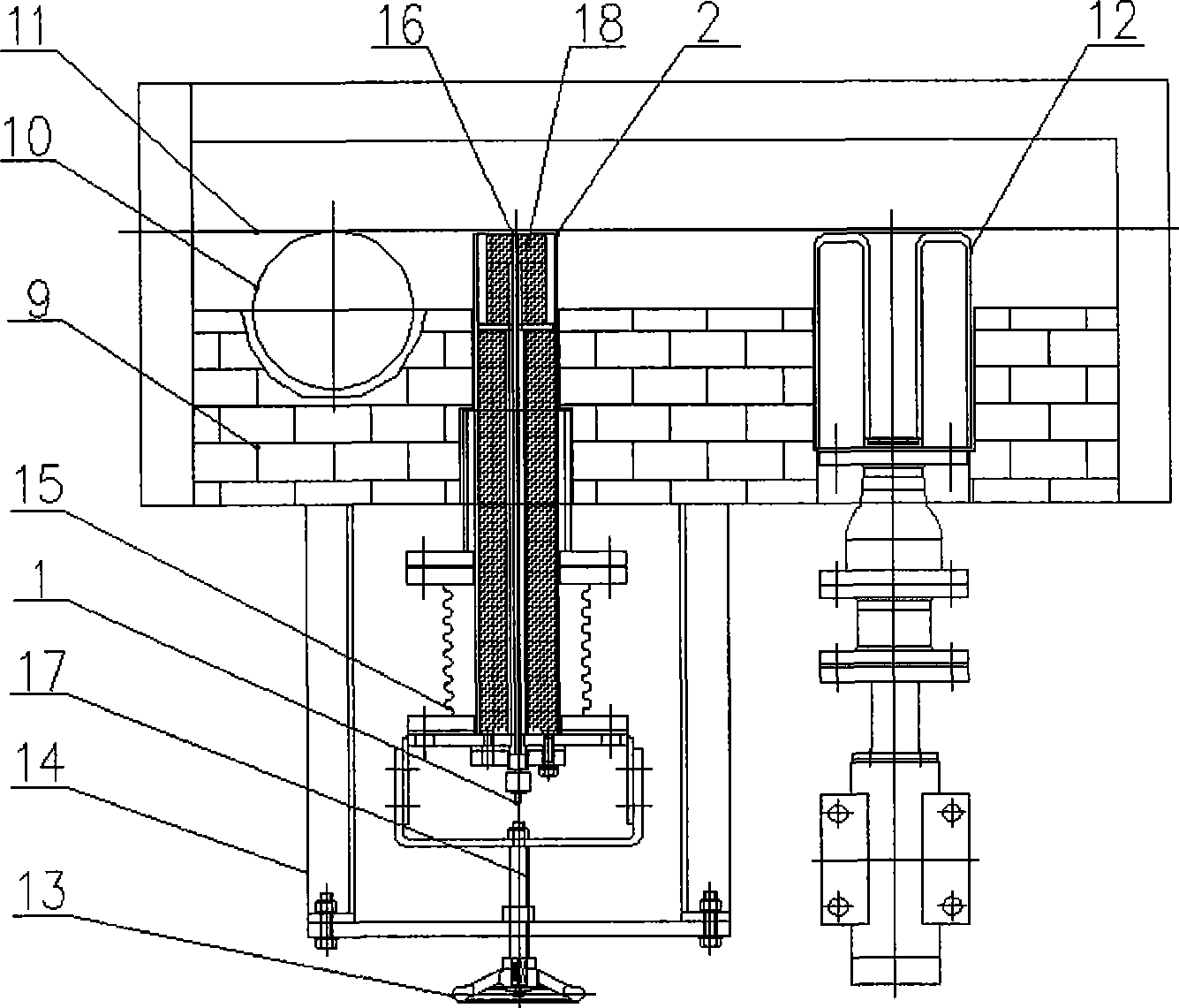

[0014] Attached below figure 2 The present invention is further described.

[0015] The present invention includes thermocouple 1; outer protective casing 2; furnace roll 10; radiant plate thermometer 12; rotating hand wheel 13; fixed frame 14; bellows 15; inner protective casing 16; connecting rod 17; .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention, belonging to the technical field of temperature measurement, discloses a device for detecting a panel thermometer of a continuous annealing furnace and a method thereof. The invention primarily comprises that: pore passages communicated with each other are arranged at the bottom of the annealing furnace and in a refractory layer of the furnace bottom, an outer casing is mounted on the inner wall of the pore passages, a thermocouple and a display device are arranged; an inner protective casing is mounted in the outer casing, high-temperature refractory fibers are filled between the inner casing and outer protective casing, the temperature-measuring thermocouple is arranged in the inner protective casing, the parts of the inner protective casing, the outer casing and the temperature-measuring thermocouple stretching out of the furnace are totally arranged in the hermetic closure of a stretchable corrugated pipe. When the radiant panel thermometer is checked, a hand wheel at the bottom of a connecting rod is rotated to move the connecting rod upwards, so as to push the inner protective casing, the outer casing and the temperature-measuring thermocouple into the position near band steels in the furnace chamber, thus realizing the measurement of the panel temperature; according to the temperature of the band steels measured by the temperature-measuring thermocouple, the radiant panel thermometer is checked in combination with the panel temperature shown by the radiant panel thermometer to obtain correct radiation coefficient. The invention is accurate in measurement, simple in structure and convenient in operation and use.

Description

technical field [0001] The invention belongs to the technical field of temperature measurement, and discloses a detection device and method for a plate thermometer of a continuous annealing furnace. Background technique [0002] Continuous annealing furnace is mainly used for recrystallization annealing of strip steel before galvanizing. The substrate of galvanized steel strip is cold-rolled sheet. Before cold rolling, the hot-rolled strip steel has equiaxed grains, and the lattice arrangement is relatively regular. During the cold rolling process, due to the dislocation of atoms in the crystal, the crystal lattice slips along a certain slip plane and direction, resulting in plastic deformation. After cold rolling, the deformation resistance increases, the plasticity deteriorates, and work hardening occurs. In order to restore its plasticity, it must undergo recrystallization annealing. After annealing, the strip steel forms new crystal nuclei in the crystal and grows int...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01K19/00G01K7/02C21D11/00G01K1/08

Inventor 周勇李静松谭小琴姜永新向锡炎

Owner CISDI ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com