DSC meter with visualization function

A technology of differential scanning calorimetry and function, which is applied in the field of differential scanning calorimeter, can solve the problems of unavailable, researched, and limited material temperature characteristics, and achieve the effect of low operating temperature, simple operation, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

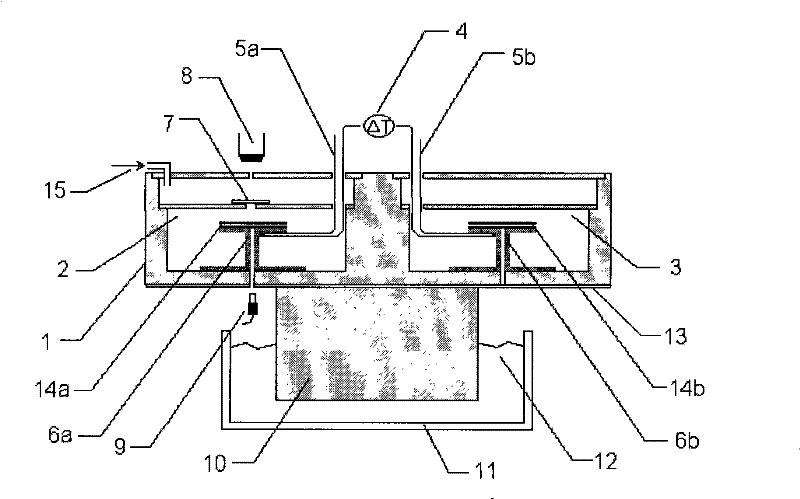

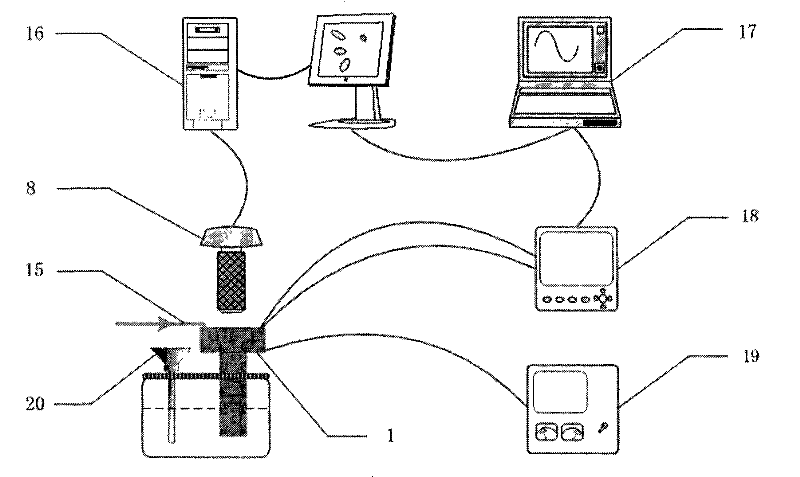

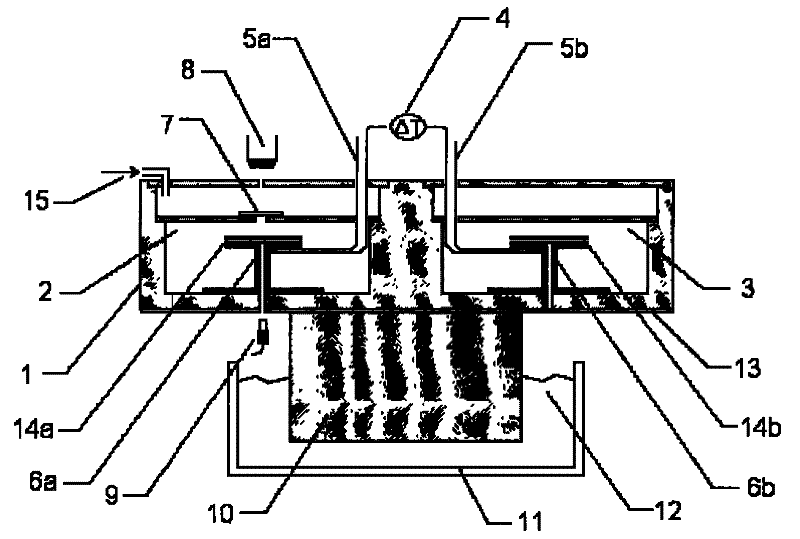

[0024] Such as figure 1 and figure 2 As shown, a differential scanning calorimeter compatible with visualization function includes a DSC workbench 1 provided with a sample cell 2 and a reference cell 3, and a device set in the sample cell 2 for carrying the sample and transferring heat flow with the sample. The first heat flow detection part 6a, the second heat flow detection part 6b set in the reference cell 3 to carry the reference object and transfer heat flow with the reference object, respectively heat up and cool down the two heat flow detection parts 6a, 6b The controlled temperature control device, the temperature recorder 18 connected to the two heat flow detection components 6a, 6b respectively through the thermocouple wires 5a, 5b, also includes a microscope camera system and an image acquisition system 16, and the microscope camera system passes through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com