Brake friction assembly for disk brake

A disc brake and component technology, applied in the parts of the brake, the type of the brake, the brake in the axial direction, etc., can solve the problem of increasing the friction area between the brake disc and the friction plate, the wear of the brake disc and the friction plate, and the increase of the brake. The problem of moving disc and friction plate can achieve the effect of good braking effect, increasing friction area and increasing braking torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

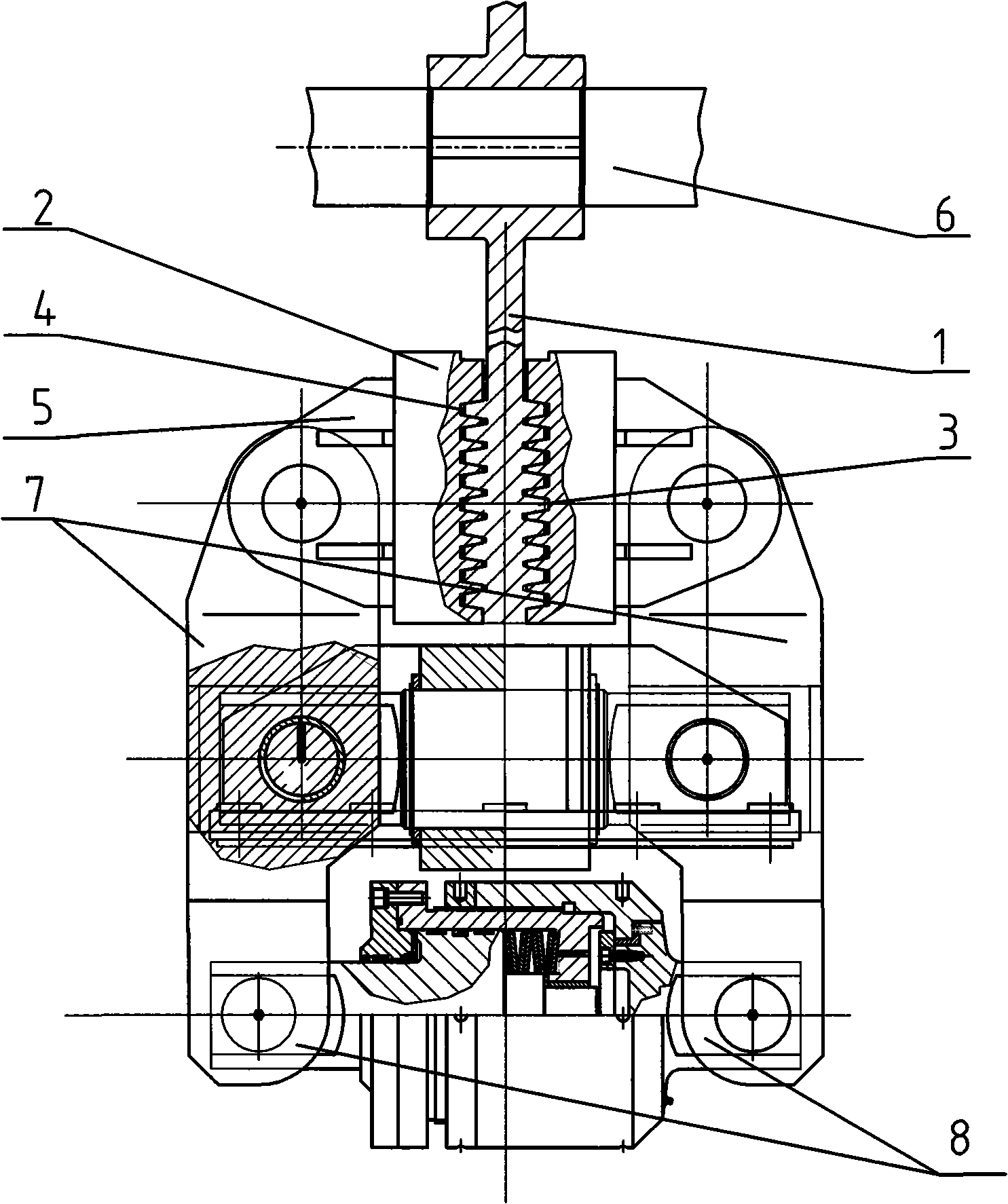

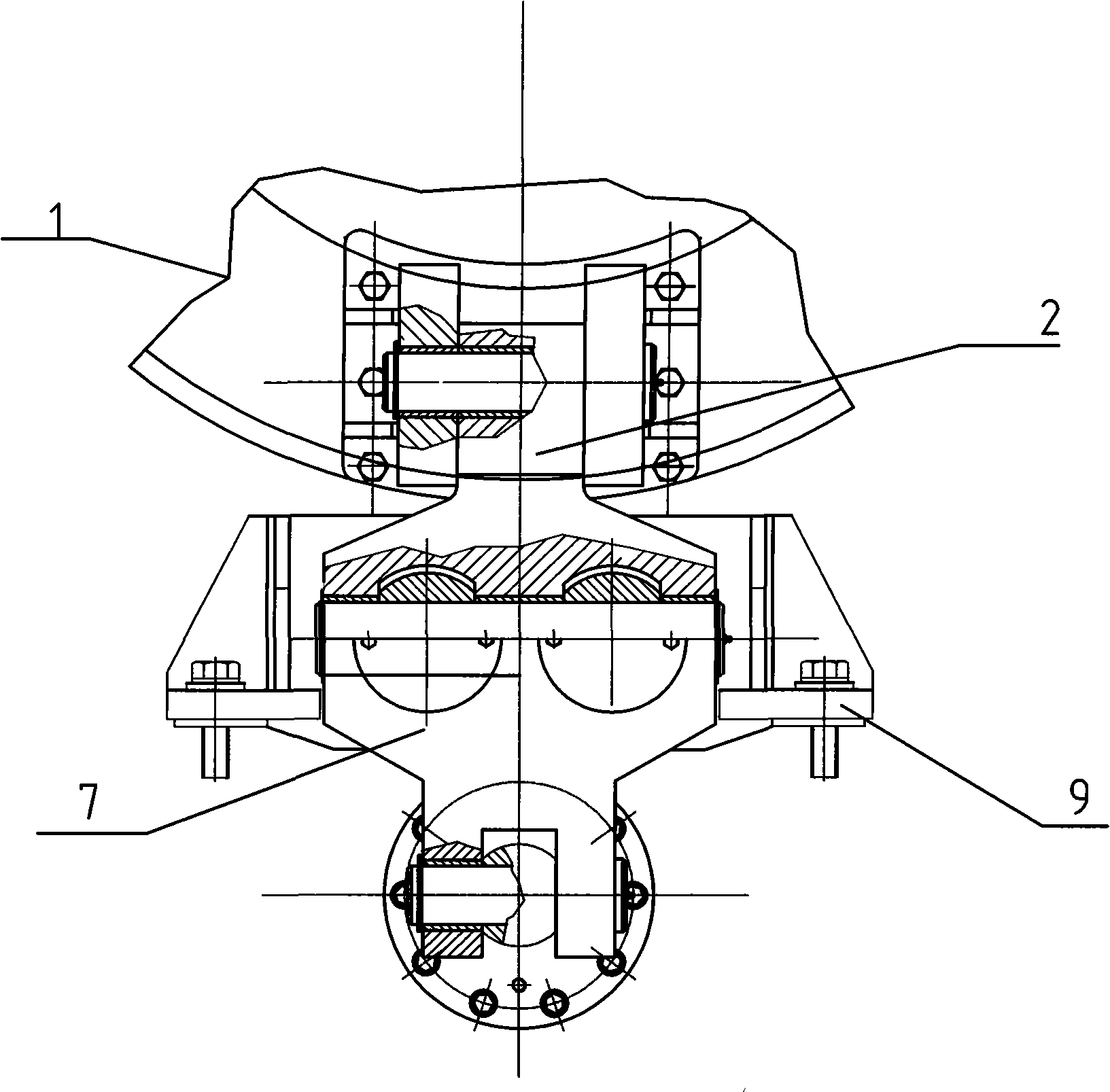

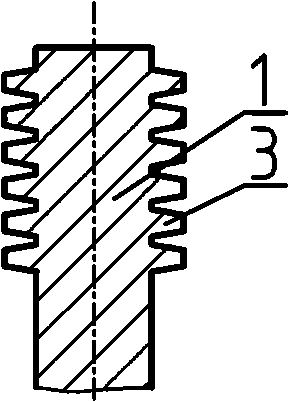

[0028] Such as Figure 1 to Figure 5 The brake friction assembly of a disc brake shown includes a bracket 5, a rotating shaft 6, a brake caliper 7, a brake disc 1, a friction plate 2 and a base 9; the end surface of the brake disc 1 is provided with nine An annular braking friction table 3 with a trapezoidal axial cross-section extending in the entire circumferential direction of the end face of the disc and uniformly distributed in the radial direction; the end face of the friction plate 2 is provided with nine annular braking friction tables with a trapezoidal and / or triangular axial cross-section. Groove 4; the brake caliper 7 is hinged on the base 9, the brake cylinder rod 8 is hinged on the brake caliper 7, the bracket 5 is connected to the brake caliper 7, and the friction plate 2 is fixedly installed on the bracket 5; The brake disc 1 is fixedly installed on the rotating shaft 6; the brake cylinder rod drives the brake caliper to press the annular brake friction groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com