Anti-runout non-collaboration target laser corner and speed measurement method and apparatus

A non-cooperative target, radial runout technology, applied in the field of optical precision measurement, can solve the problem that the rotating body cannot perform high-precision angle measurement, and achieve the effect of high-precision real-time measurement, small size, stable and reliable performance

Inactive Publication Date: 2010-11-10

BEIJING INSTITUTE OF TECHNOLOGYGY

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

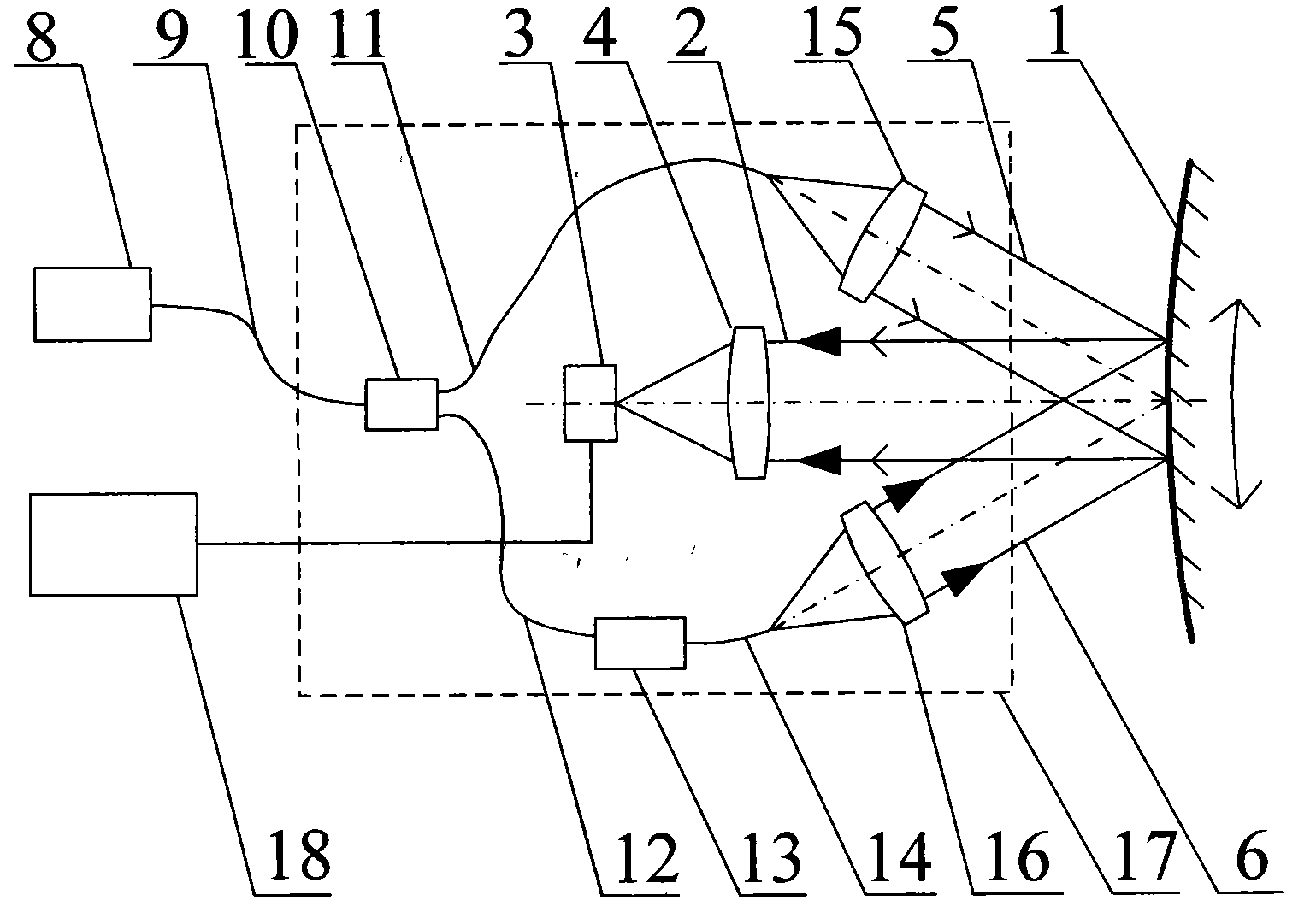

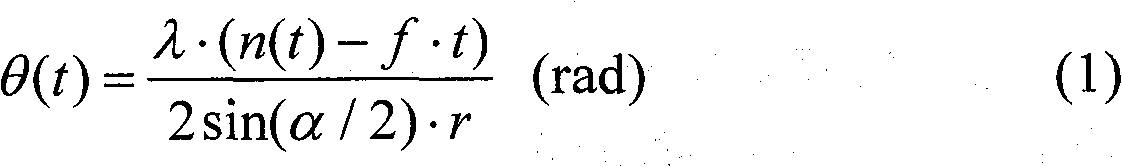

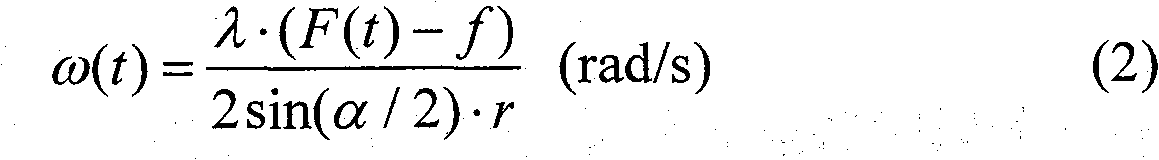

The first purpose of the present invention is to solve the problem that a rotating body with a large radial runout cannot be measured with high precision, and propose a non-cooperative target laser rotation angle and speed measurement method that is resistant to radial runout. This method uses two laser beams to irradiate the rotation The diffuse reflection of the rotating surface of the body, using the Doppler frequency shift effect of the diffuse reflection light emitted in the radial direction, is not sensitive to the radial runout of the rotating body, and then achieves high-precision rotation angle measurement through interference detection technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to the technical field of optical precision measurement, relating to a non-cooperative target laser corner and speed measuring method and device for radial run-out prevention. The method uses two beams of laser to irradiate the diffuse rotary surface of a rotator and uses the characteristic that doppler shift effect of diffused reflection light irradiated along radial direction is insensitive to radial run-out of the rotator so that high-precision corner measurement is realized by interference detection technique. The measuring device in the invention comprises a laser and further comprises a photoelectric sensor, a convergent mirror, an optical fiber branching device, optical fibers, a frequency shifter, a first circuit of collimating mirror and a second circuit of collimating mirror; the invention uses the optical fibers to construct light paths, thereby reducing the volume of a measuring head; and simultaneously a plurality of measuring heads are installed on the rotary circumference of the rotator, thereby improving harmonic suppression characteristic of a single measuring head by using an error separation technology and eliminating the influence of radial run-out of the rotator on measuring results. The device has the characteristics of small volume, high real-time and good measuring stability.

Description

Anti-runout non-cooperative target laser rotation angle and velocity measurement method and device technical field The invention belongs to the technical field of optical precision measurement, and can measure high-precision angle, angular velocity, and angular acceleration for a rotating body with large radial runout, and provide accurate and fast angle data for realizing high-precision rotation control of a large-scale electromechanical angle system. technical background Rotation angle measurement sensors are widely used in electromechanical systems, especially the acquisition of the rotation angle value of the rotating shaft in large electromechanical turntables, and the motion control of large multi-dimensional turntables are inseparable from rotation angle measurement sensors. However, the angle measurement sensors widely used in electromechanical angle systems, such as grating angle encoders, inductive synchronous angle sensors, and magnetic grid angle measurement sen...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01B11/26G01P3/36G01P15/00G01B9/02

Inventor 赵维谦孙若端唐彦邱丽荣

Owner BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com