Machine for stirring flour dough

A technology of stirring spiral and curing, applied in food science, mixing/kneading with vertical installation tools, etc., can solve the problems of high labor intensity, unsanitary, low efficiency, etc., and achieve the effect of high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

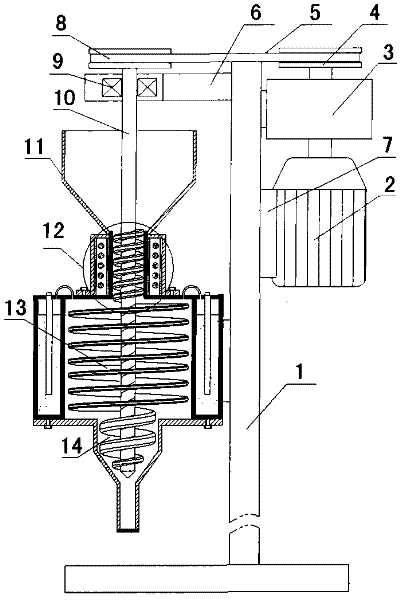

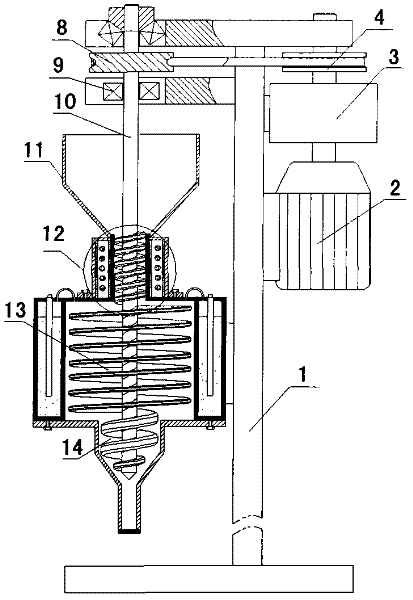

Embodiment 1

[0014] Embodiment 1: refer to Figure 1~5 . Stir dough machine, the primary curing device 12 is an electric heating curing device, the electric heating curing device is composed of an inner tube 15, an electric heating ring 16, a heat insulation layer 17 and an outer shell 18, and the electric heating ring 16 is sleeved on the inner tube 15, separated Heat insulation layer 17 is enclosed within on the electric heating ring 16, and shell 18 is enclosed within on the insulation layer 17, and the formation of electric heating ring 16 is prior art, does not describe here. The secondary curing device 13 is an electric heating steam curing device. The electric heating steam curing device is composed of a sleeve type water tank 21, an electric heating tube 20, and a steam conduit 19. The electric heating tube 20 is located in the water tank 21 and uses a steam conduit 19 It communicates with the inner tube cavity of the water tank 21. The discharge port of the hopper 11 is communic...

Embodiment 2

[0015] Embodiment 2: on the basis of embodiment 1, with reference to appended Figure 6 . The secondary curing device 13 is an electric heating curing device, which is equipped with a steam generator and a water vapor guiding pipe, and one end of the water vapor guiding pipe communicates with the inner lumen in the electric heating curing device, and the other is connected with the electric heating curing device. One end communicates with the steam generator, and the steam generator is made of a container, an electric heating tube and a water replenishing device. The container, the electric heating tube and the water replenishing device are all prior art, and will not be described here.

Embodiment 3

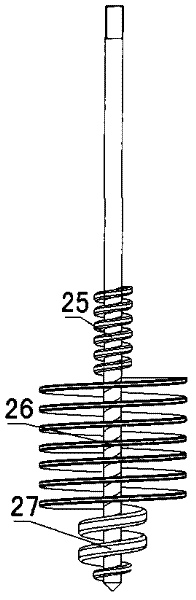

[0016] Embodiment 3: on the basis of embodiment 1, adopt the method of beating dough machine to stir dough, close the switch in the discharge port of extruder 14, corn flour or other flour and become paste, put in the hopper 11, Start the motor 2, the motor 2 adjusts the rotating belt to the required speed through the transmission 3 or the frequency converter and drives the driving pulley 4 to rotate, the driving pulley 4 drives the driven runner 6 through the belt 5, and is fixed on the screw shaft 10 Driven by the driven runner 8, the upper driven runner 8 drives the variable screw shaft 10 to rotate, and the pasty cornmeal or other pasty noodles are conveyed under the action of the conveying screw 25 in the variable screw shaft. When passing through the primary aging device 12, the pasty cornmeal or other pasty noodles after the primary aging are driven by the stirring screw 26 after the primary aging device is aged by the primary aging device. The generated high temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com