Core sample sealing device in true triaxial test

A sealing device and true triaxial technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of rock sample stress concentration, etc., and achieve the effect of easy installation, solving the problem of rock sample stress concentration, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

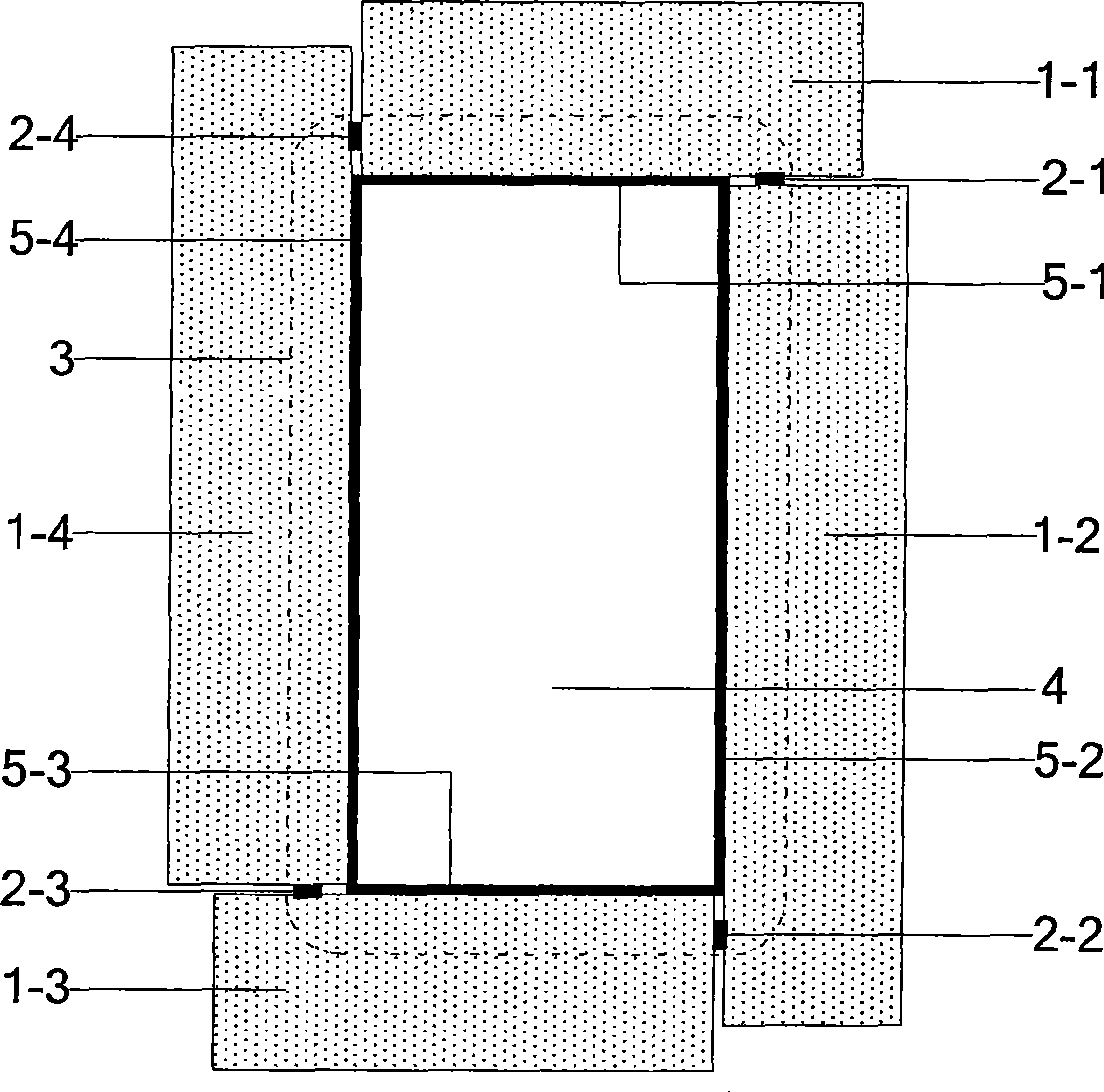

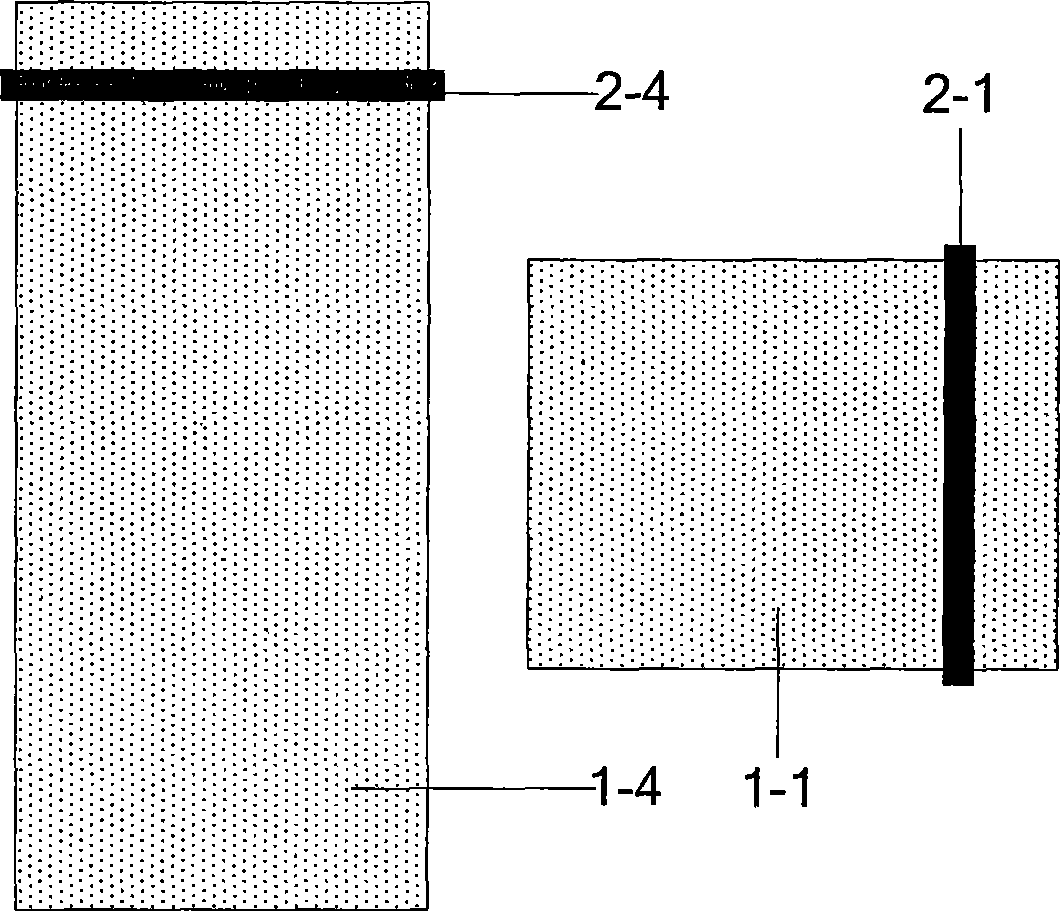

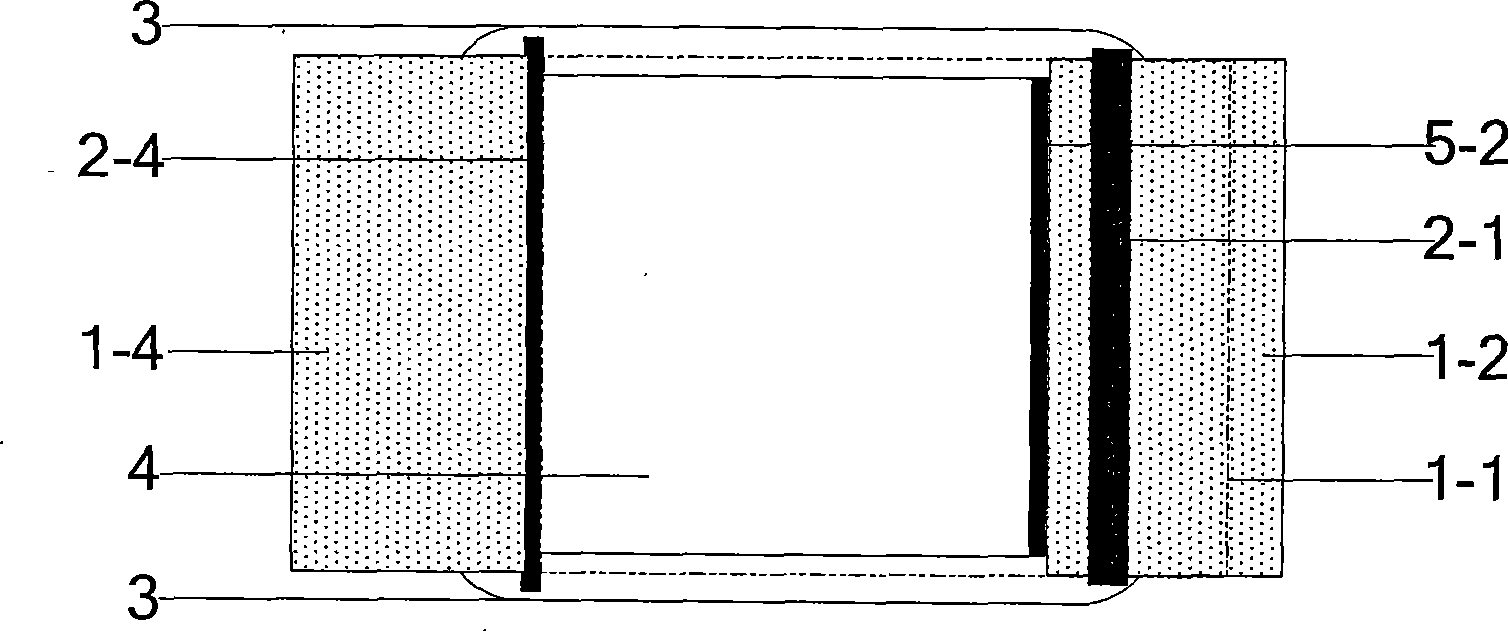

[0018] Below in conjunction with accompanying drawing, the present invention will be further described:

[0019] A sealing device for rock samples in a true triaxial test, the device includes pressure pads 1-1, 1-2, 1-3, 1-4, and sealing rubber strips 2-1, 2-2, 2-3 , 2-, silica gel coating 3, rock sample 4, anti-friction pads 5-1, 5-2, 5-3, 5-4, the connection relationship is: according to figure 1 , 2 , 3, four bearing pads 1-1, 1-2, 1-3, 1-4 are respectively placed on the four ends of the rock sample 4, and each bearing pad 1-1, 1 One end of -2, 1-3, 1-4 is aligned with the rock sample 4 and connected end to end to form an interlocking type. Each pressure pad 1-1, 1-2, 1-3, 1-4 has a groove near the end of the rock sample 4, and a sealing rubber strip 2-1, 2-2, 2-3 , 2-4 are placed therein, and the sealing rubber strips 2-1, 2-2, 2-3, 2-4 are slightly longer than the groove. A piece of anti-friction pad 5- 1, 5-2, 5-3, 5-4, used to reduce the end friction and the fricti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com