Magnetic gear transmission

A magnetic gear and transmission technology, applied in the direction of electrical components, electromechanical devices, electromechanical transmission devices, etc., can solve the problems of low noise, low efficiency, high noise, etc., and achieve the effects of low noise, low overcoming efficiency, and small wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings.

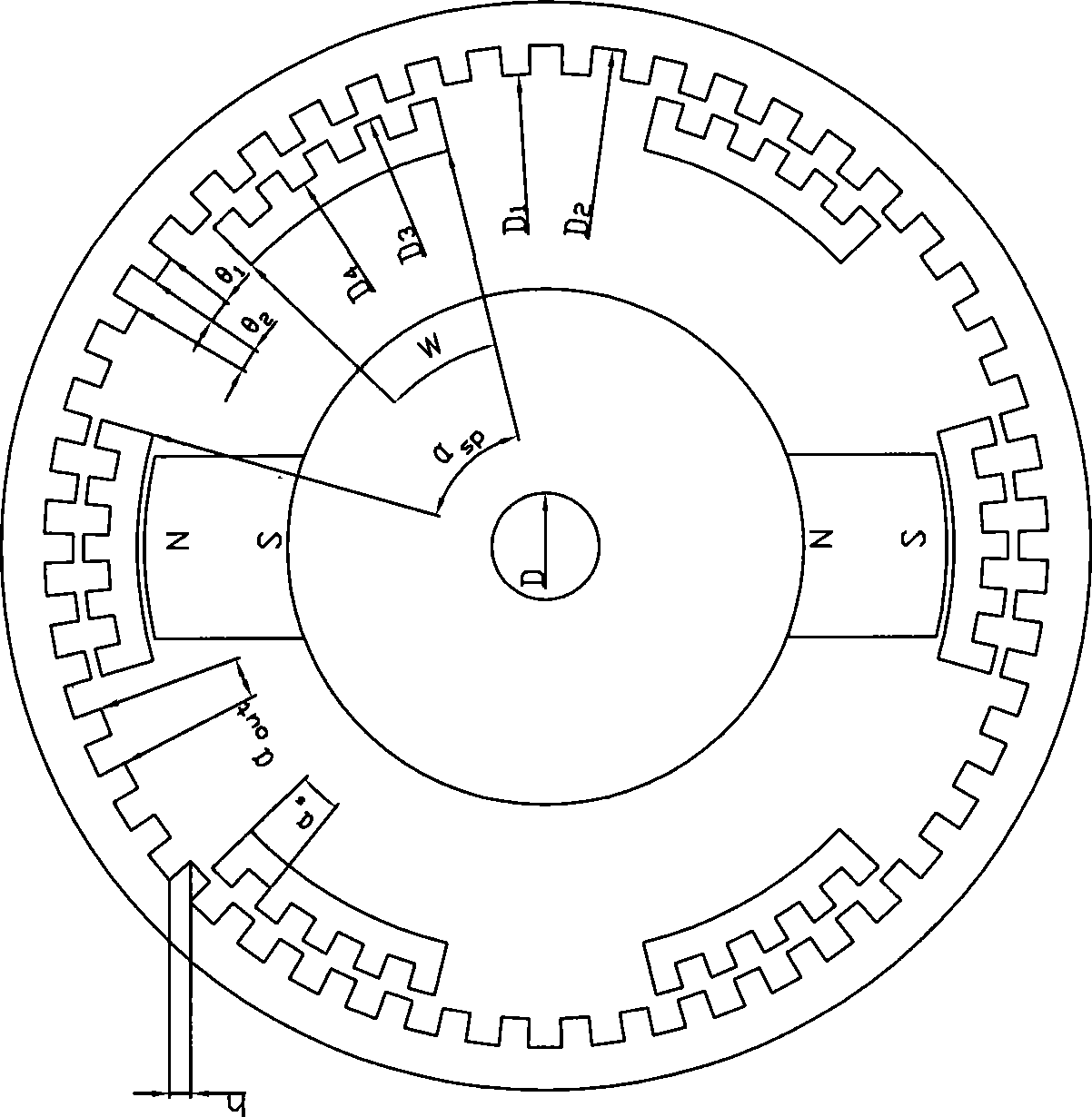

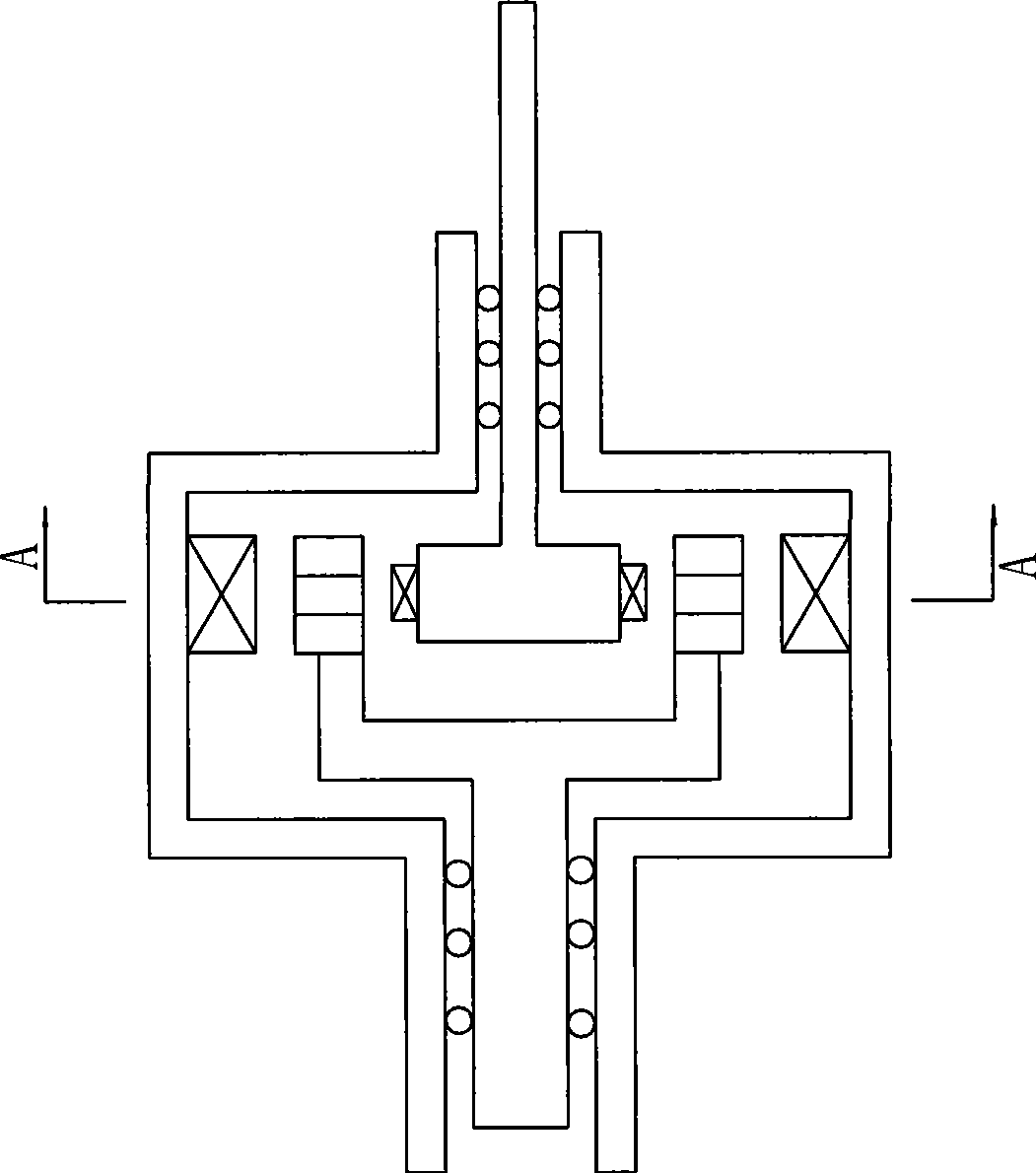

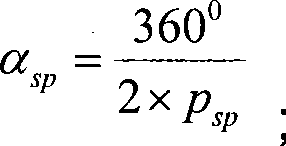

[0028] The so-called gear transmission means that when one gear rotates at one speed, the other gear rotates at a different speed. The invention realizes the change of different rotating speeds based on the theory of the magnetic field. see figure 1 with figure 2 , the inner rotor of the present invention includes magnetic poles made of permanent magnet materials; there are N on the stator t comb teeth; N on the outer rotor sp poles.

[0029] see figure 1 with 2 , this embodiment includes an inner rotor, an outer rotor, and a stator, and the base is radially concentric and embedded, and a non-contact structure is left between the inner rotor and the outer rotor, and the outer rotor and the stator; the inner rotor Located in the inner layer, there is at least one pair of inner rotor poles of permanent magnet material arranged in pairs; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com