Optimizer, photovoltaic power generation system and photovoltaic power generation control method

An optimizer and controller technology, applied in photovoltaic power generation, photovoltaic modules, electrical components, etc., can solve the problems of high communication cost, high communication cost, communication robust power conversion noise and surrounding environmental noise interference, etc., to overcome transmission Effect of short distance and reduction of communication cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

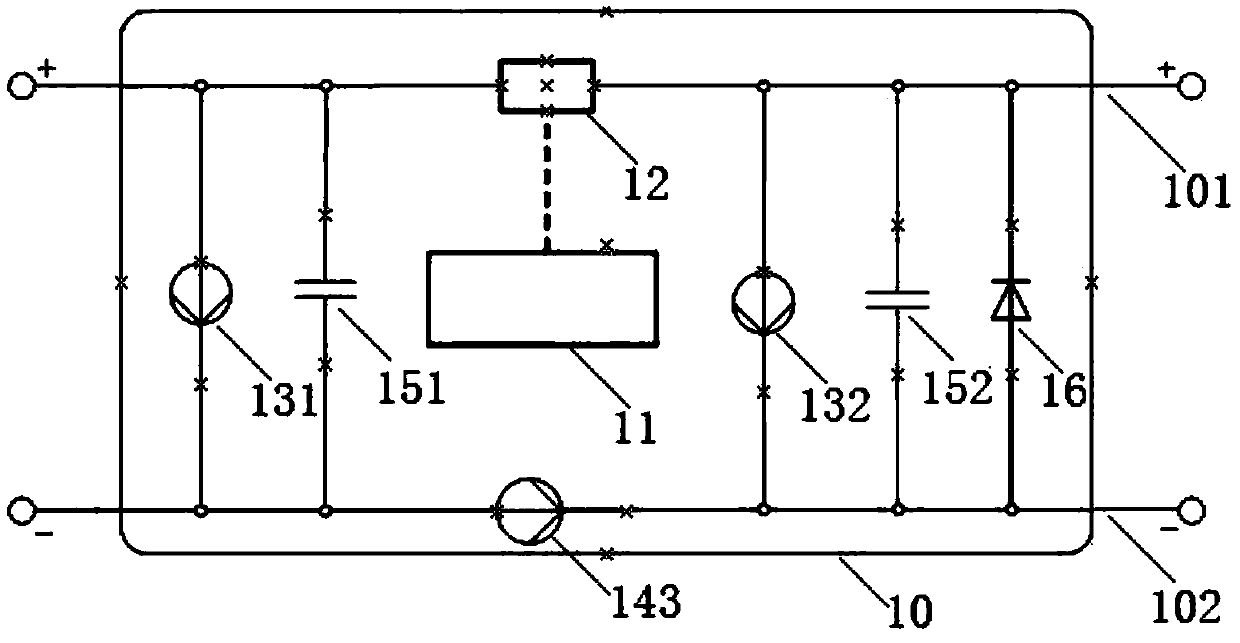

[0023] Such as figure 1 Shown is the optimizer 10 of this embodiment, which includes a positive pole branch 101, a negative pole branch 102, a first voltage sensor 131, a first capacitor 151, a second voltage sensor 132, a second capacitor 152, a bypass diode 16, The optimizer switch 12 (SW_optimizer), the optimizer controller 11 and the third current sensor 143 .

[0024] The optimizer controller 11 is communicatively connected with the optimizer switch 12 , and the communication methods such as wire or wireless can be used. The operating state of the optimizer switch 12 is controlled by the control command issued by the optimizer controller 11 .

[0025] The first voltage sensor 131, the first capacitor 151, the second voltage sensor 132, the second capacitor 152, and the bypass diode 16 are sequentially connected in parallel between the positive branch 101 and the negative branch 101; the optimizer switch 12 is set on the first capacitor 151 On the positive branch 101 betw...

Embodiment 2

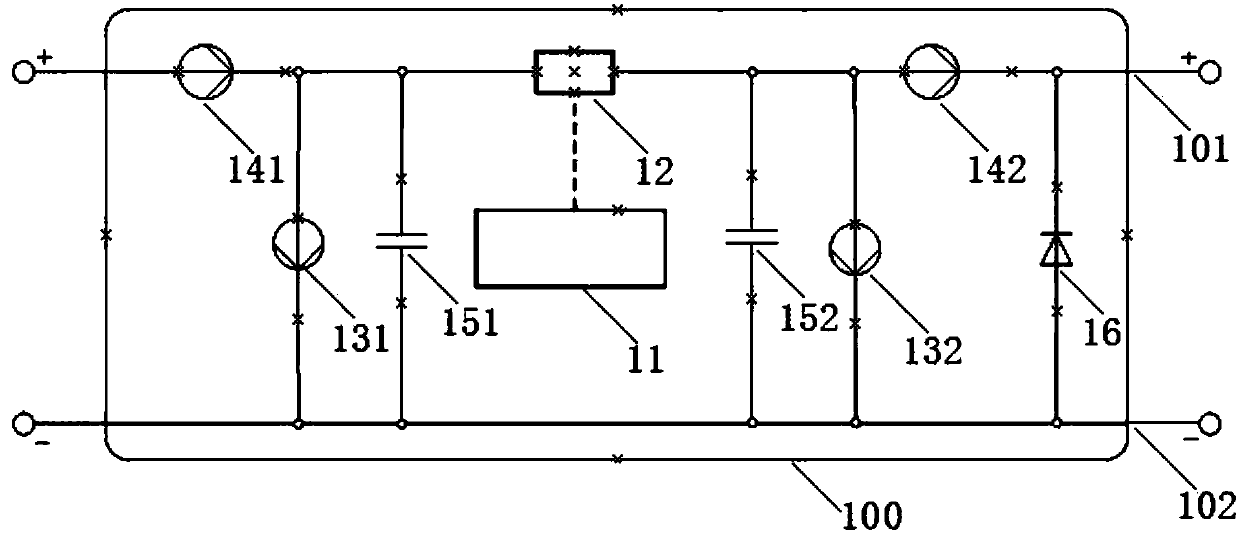

[0031] Such as figure 2 Shown is the optimizer 100 of this embodiment, which includes a positive pole branch 101, a negative pole branch 102, a first voltage sensor 131, a first capacitor 151, a second capacitor 152, a second voltage sensor 132, a bypass diode 16, The optimizer switch 12 , the optimizer controller 11 , and the first current sensor 141 and the second current sensor 142 .

[0032] The optimizer controller 11 is communicatively connected with the optimizer switch 12; a first voltage sensor 131, a first capacitor 151, a second capacitor 152, a second voltage sensor 132, and a bypass are sequentially connected in parallel between the positive branch 101 and the negative branch 102 Diode 16; the first current sensor 141 is arranged on the positive pole input terminal of the optimizer and the positive pole branch 101 of the optimizer switch 12 (specifically, for example, it can be between the positive pole input terminal of the optimizer and the first voltage sensor...

Embodiment 3

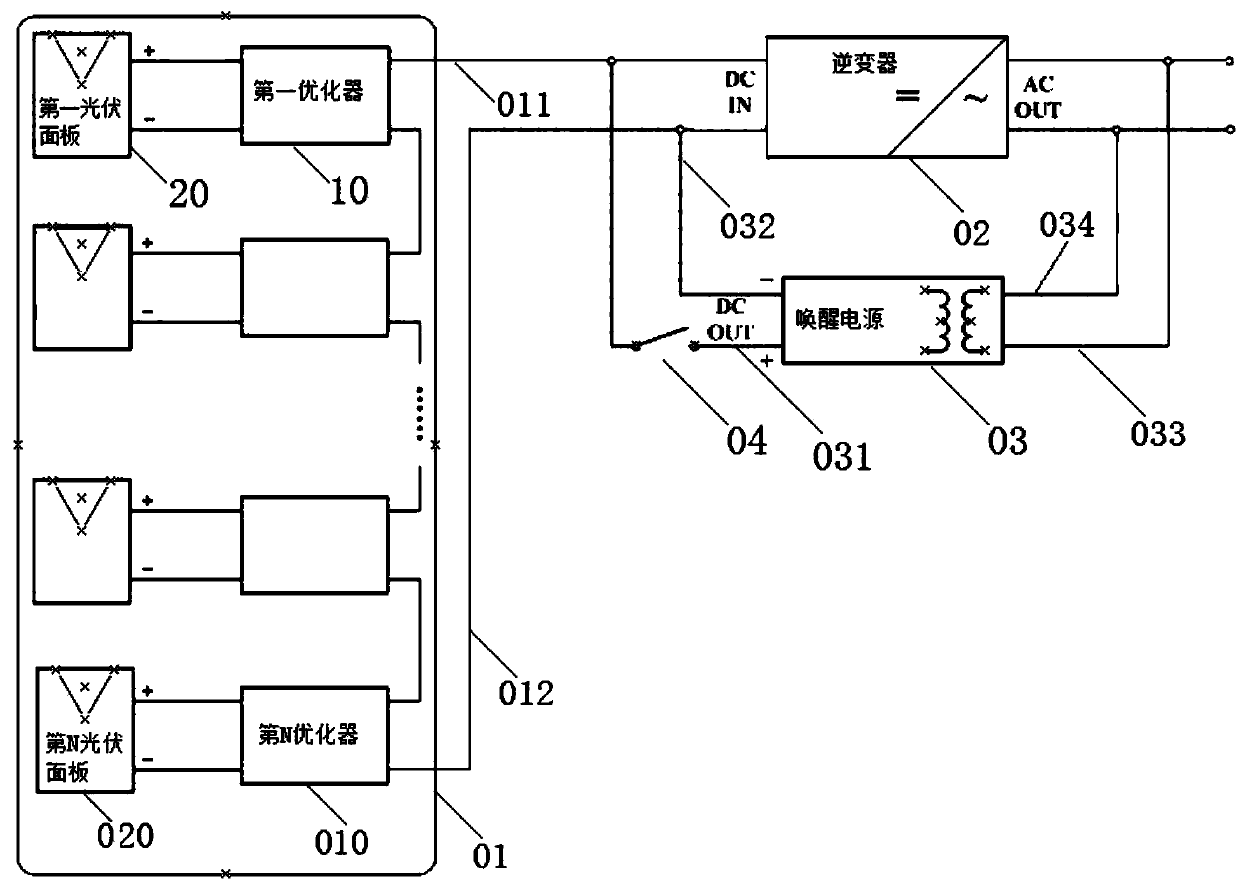

[0035] Such as image 3Shown is the distributed photovoltaic power generation system of this embodiment, which includes a photovoltaic string unit 01, a photovoltaic inverter 02 (Solar / PV Inverter), a wake-up power supply 03 (Start-up Source) and a wake-up switch 04 (SW_start).

[0036] The photovoltaic string unit 01 leads to a positive transmission line 011 and a negative transmission line 012. The positive transmission line 011 and the negative transmission line 012 are introduced from the input end of the inverter 02 and drawn out from the output end of the inverter 02, and then connected to the grid.

[0037] The wake-up power supply 03 is connected in parallel with the inverter 02; the wake-up switch 04 is arranged on the parallel branch of the wake-up power supply 03 and the inverter 02.

[0038] Specifically, the positive power line 031 drawn from the input end of the wake-up power supply 03 is connected to the positive transmission line 011 on the input side of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com