Double-thread hollow coring drill rod

A hollow drill pipe, double thread technology, applied in drill pipe, drill pipe, drilling equipment, etc., can solve the problems of not representing the original occurrence and structure of sediments, without considering sediment disturbance, etc., to improve the coring rate, The effect of reducing disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

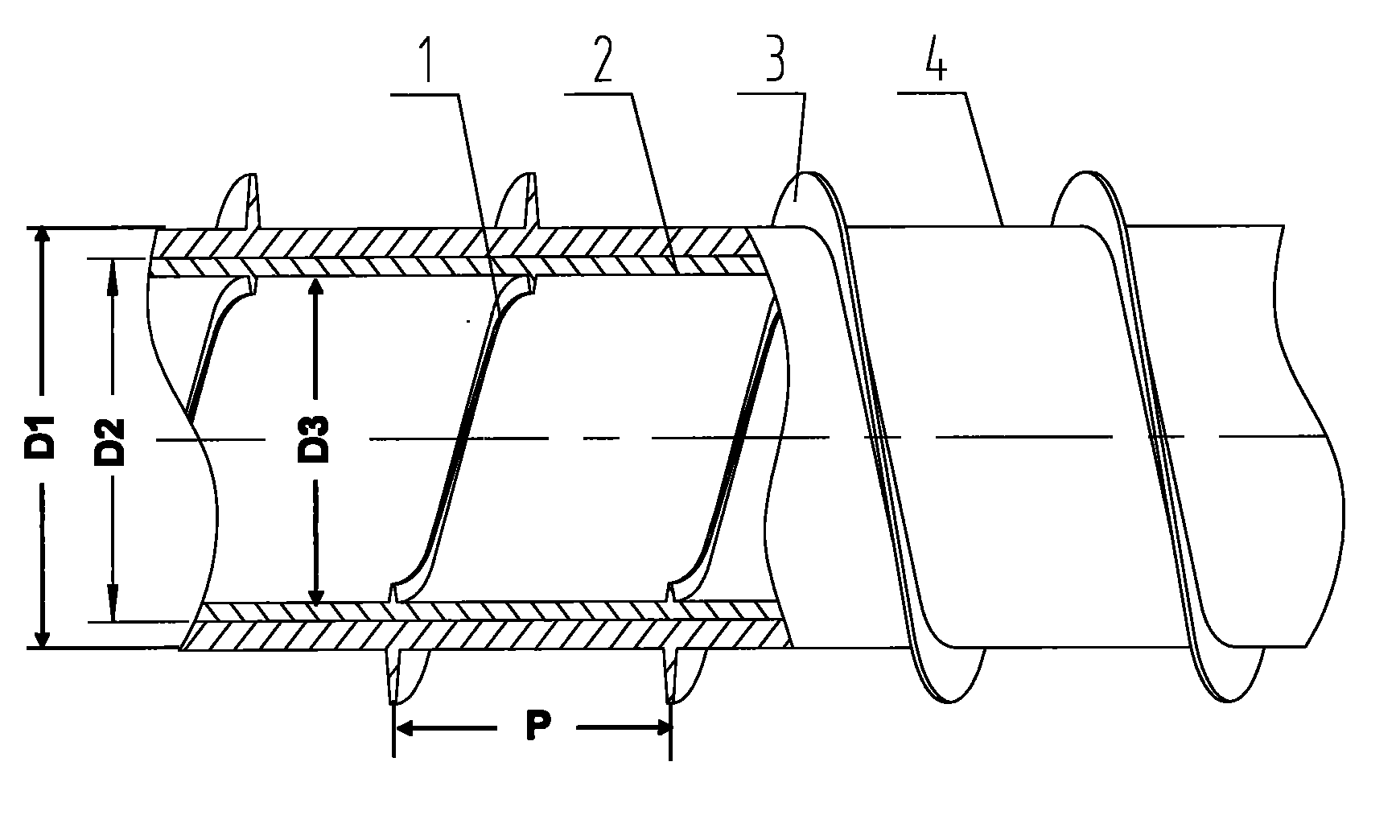

[0018] Such as figure 1 As shown, the metal hollow drill pipe 4 outer diameter (not including the outer thread) D1 is 116mm; the inner diameter D2 is 100mm, which is also the outer diameter of the polymer liner 2; the inner diameter D3 of the polymer liner 2 is 90mm (not including the inner thread) teeth); screw pitch P is 100mm.

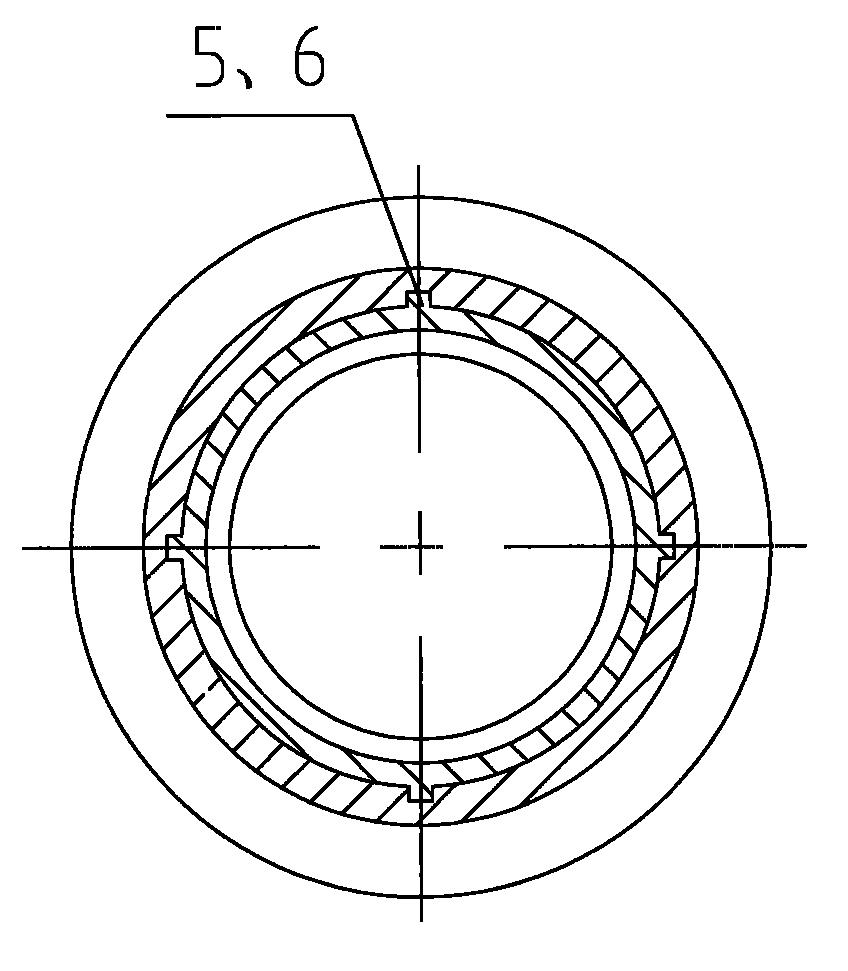

[0019] Such as figure 2 As shown, a groove 5 is provided on the metal hollow drill pipe 4 , and a convex wedge 6 is provided on the polymer liner 2 . The convex wedge 6 is a linear convex wedge on the outer wall of the polymer liner 2, its thickness d is 3 mm, its width w is 5 mm, and the groove 5 matches it. Before use, the polymer liner 2 with internal threads is packed into the metal hollow drill pipe 4. After the groove 5 and the convex wedge 6 are combined, the axial positions of the drill pipe and the liner are fixed and cannot rotate freely. After drilling, the liner is removed from the drill pipe to obtain the core.

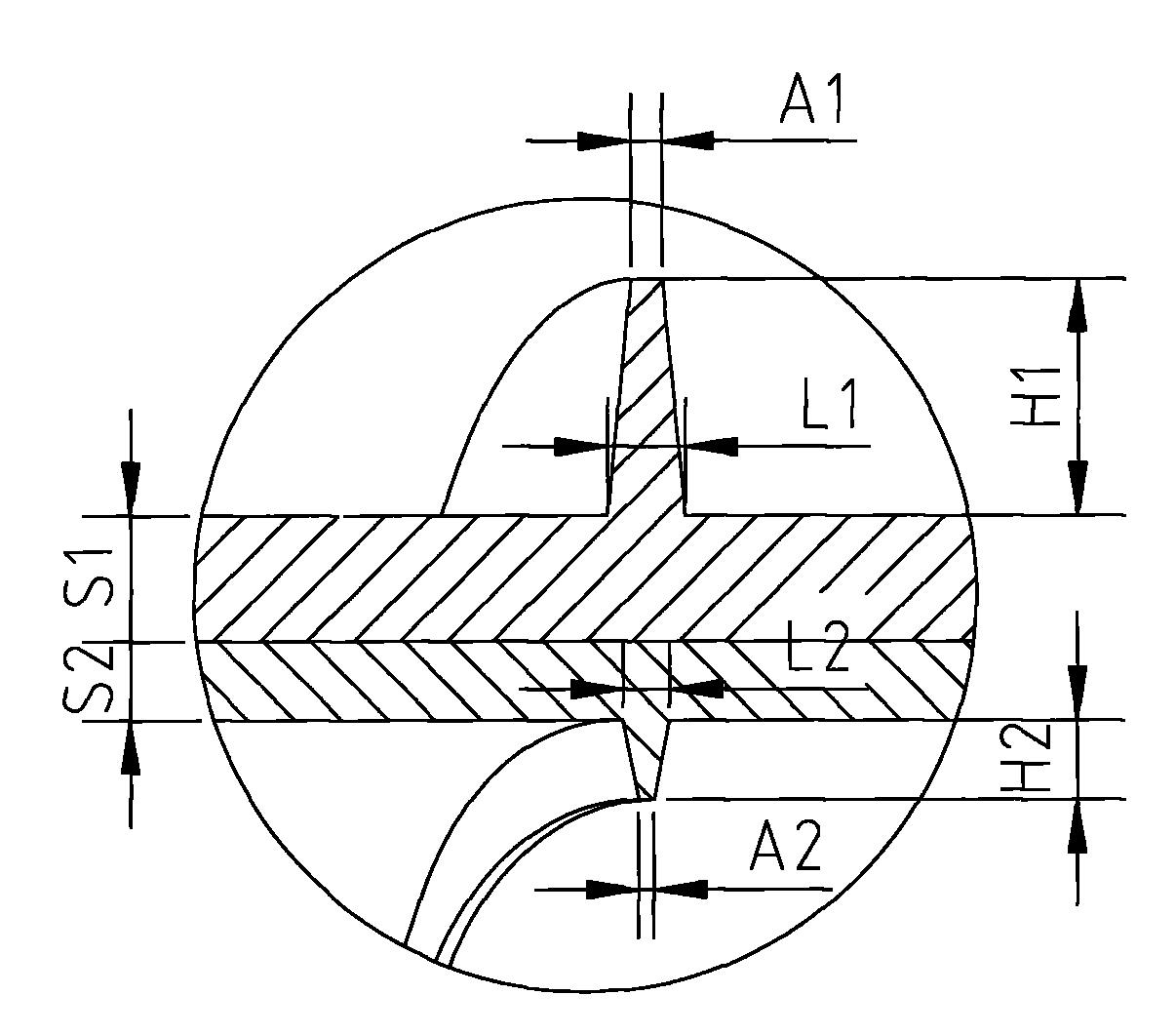

[0020] image 3 I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com