Gear shift mechanism of manual transmission

A technology of manual transmission and gear selection, which is applied in the field of automobile transmission, can solve the problems of multiple gear selection mechanisms and complex structures, and achieve the effect of simple and compact structure and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

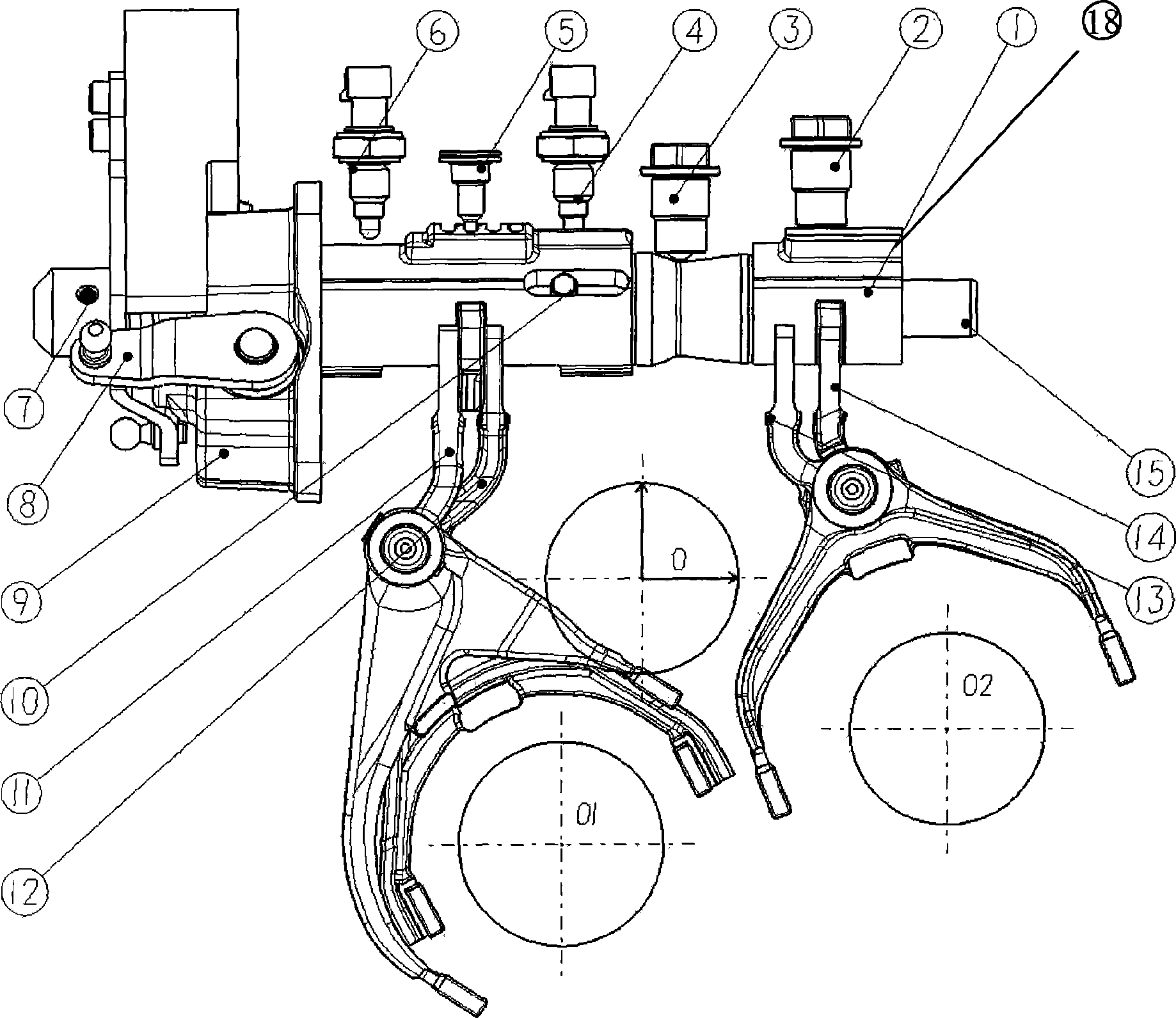

[0019] Such as figure 1 As shown, points O, O1, and O2 are the axes of the drive shaft of the transmission and the two auxiliary shafts respectively, and the three shafts are respectively installed on the transmission housing through bearings. One of the auxiliary shafts is provided with a gear fork 11 for 1 / 2 gear and a gear fork 12 for 5 / 6 gear, and the other auxiliary shaft is provided with a reverse gear fork 13 and a gear fork for 3 / 4 gear. Bit shift fork 14.

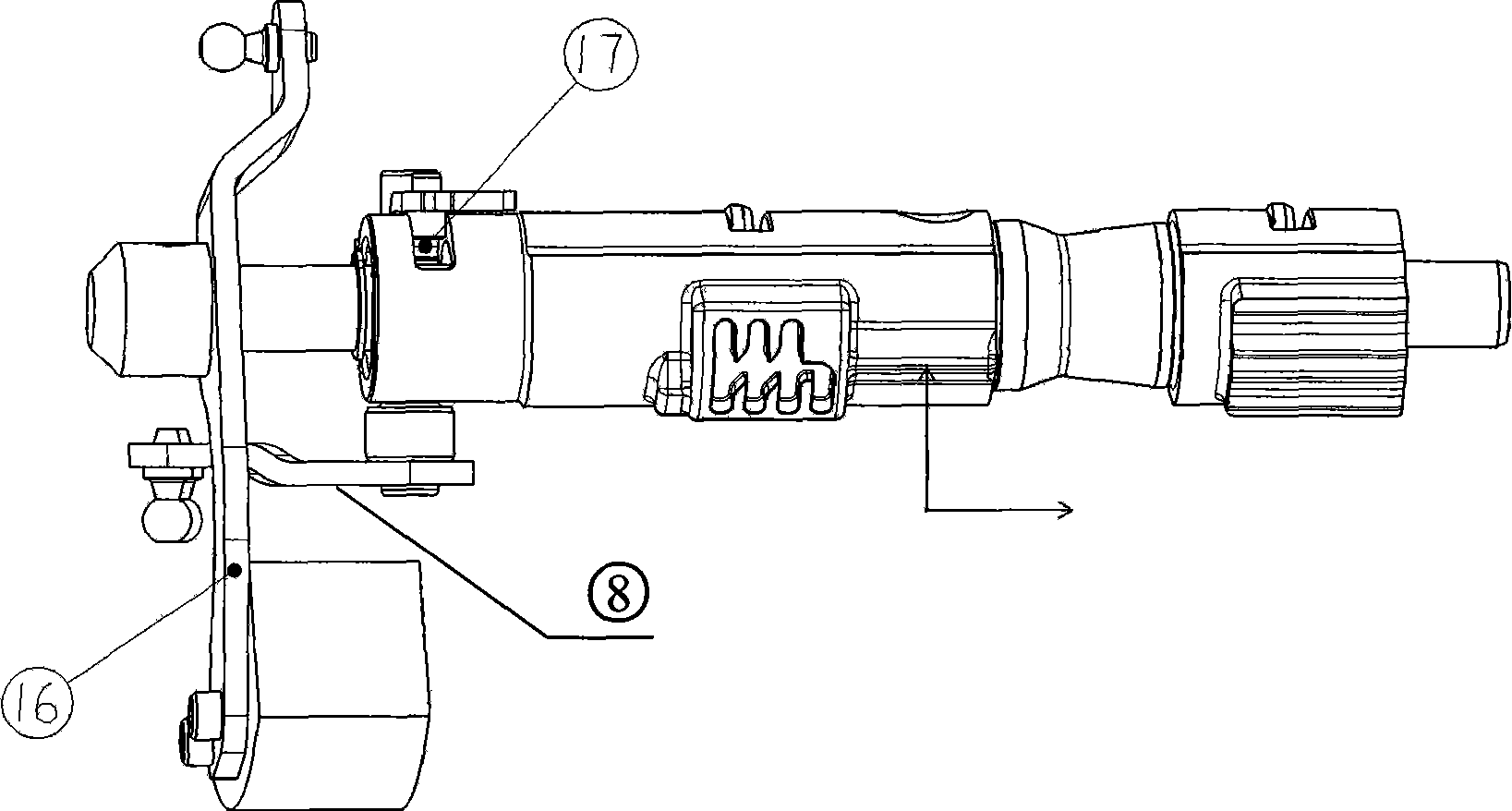

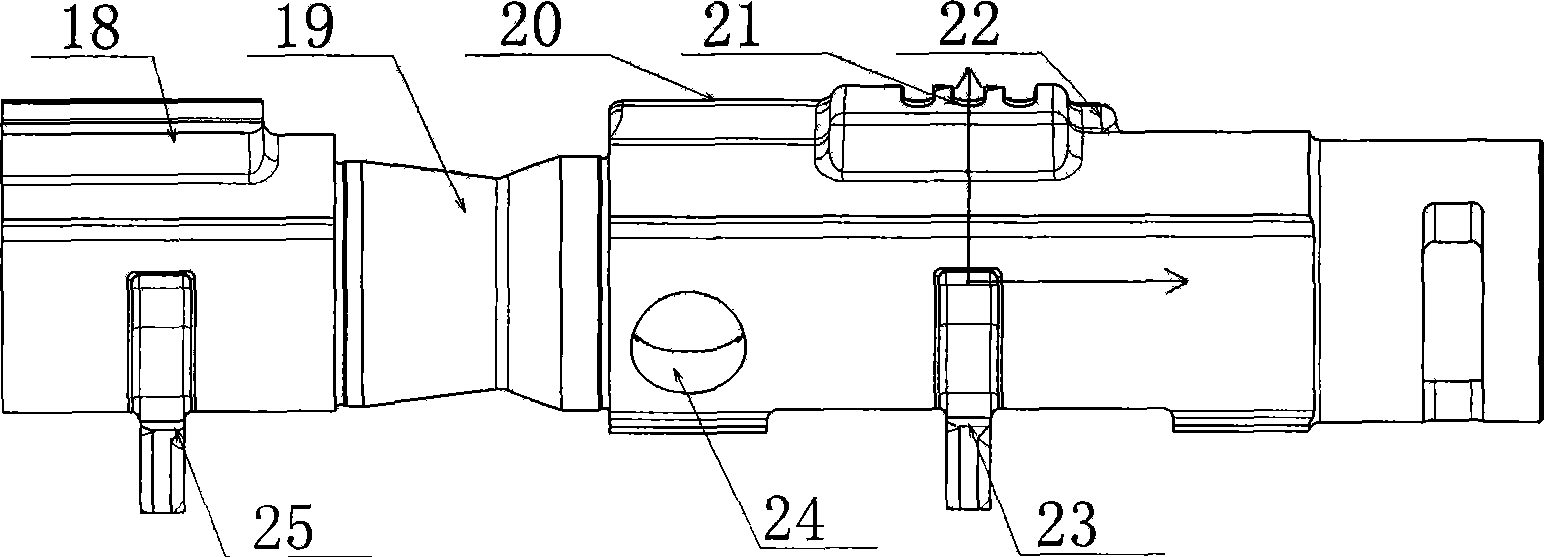

[0020] combine figure 1 , figure 2 , the wooden invention comprises a selection shift shaft 15, and the selection shift sleeve 1 that is sleeved on the selection shift shaft 15. One end of fixed row pin 2, gear selection return pin 3, neutral switch 4, interlock pin 5 and reverse gear switch 6 is equipped with a ball, and the other end is fixedly installed on the transmission case, and a retractable spring is installed inside . The gear shift rocker arm assembly 16 is fixedly connected to one end of the gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com